Cable anti-damage wall-penetrating bushing protector

An anti-damage and protector technology, applied in the direction of electrical components, etc., can solve the problems of high friction, limited anti-wear effect, and wear of the clamping position of the cable, so as to ensure shock absorption and anti-wear performance, and use The effect of simple and convenient operation and streamlined structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

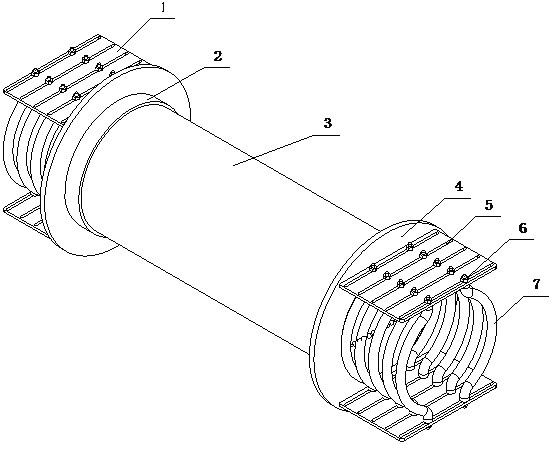

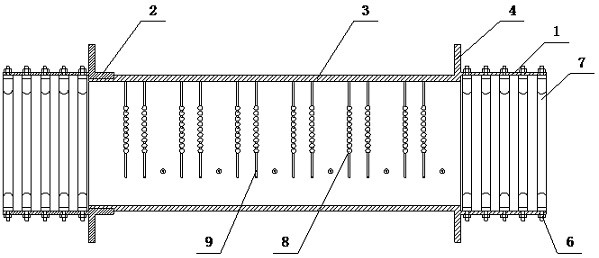

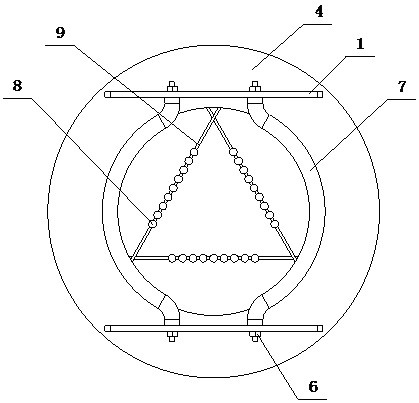

[0020] An anti-damage wall-piercing sleeve protector for cables of the present invention is realized in the following way: a cable-damage-proof wall-penetrating sleeve protector of the present invention consists of a fixing plate (1), a connecting sleeve (2), and a main sleeve ( 3), the limit plate (4), the chute (5), the locking screw (6), the guide hoop (7), the ball (8) and the support rib (9), and the connecting sleeve (2) is screwed respectively On one end of the main casing (3), a limiting plate (4) is fixed on the other end of the main casing (3), between the limiting plate (4) and the wall of the main casing (3) The included angle is an acute angle, and the limiting plate (4) is fixed on the connecting sleeve (2). The included angle between the limiting plate (4) and the wall of the connecting sleeve (2) is an acute angle, and the two fixing plates (1) Symmetrically placed on the limit plate (4), the fixed plate (1) is provided with a plurality of equidistantly distrib...

Embodiment 2

[0023] The difference between this embodiment and Embodiment 1 is that one pair of guide hoops (7) is increased into two pairs, and the two ends of the guide hoops (7) are provided with connecting shafts (10), and the two pairs of guide hoops (7) ) on the connecting shaft (10) is connected through the fixed piece (11), and the fixed piece (11) is connected with the locking screw (6); when in use, the two pairs of guide hoops (7) can be rotated and adjusted according to the bending requirements ) to improve the arc fineness of its guide bending;

[0024] The angle between the limiting plate (4) and the wall of the main casing (3) is an acute angle, and the angle between the limiting plate (4) and the wall of the connecting sleeve (2) is an acute angle design. During installation, it can elastically push the wall and enhance the connection strength of the protective structure;

[0025] The chute (5) is designed as a long trough, so that the guide hoop (7) can slide in the chute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com