Protocol conversion module between robot and welding equipment and conversion method thereof

A protocol module and welding equipment technology, which is applied in the protocol conversion module and its conversion field between robots and welding equipment, can solve the problems of ineffective industrial enterprises, complexity, difficulty in adapting a single protocol to the market, etc., and achieve fast connection transmission speed , the effect of reducing switching costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

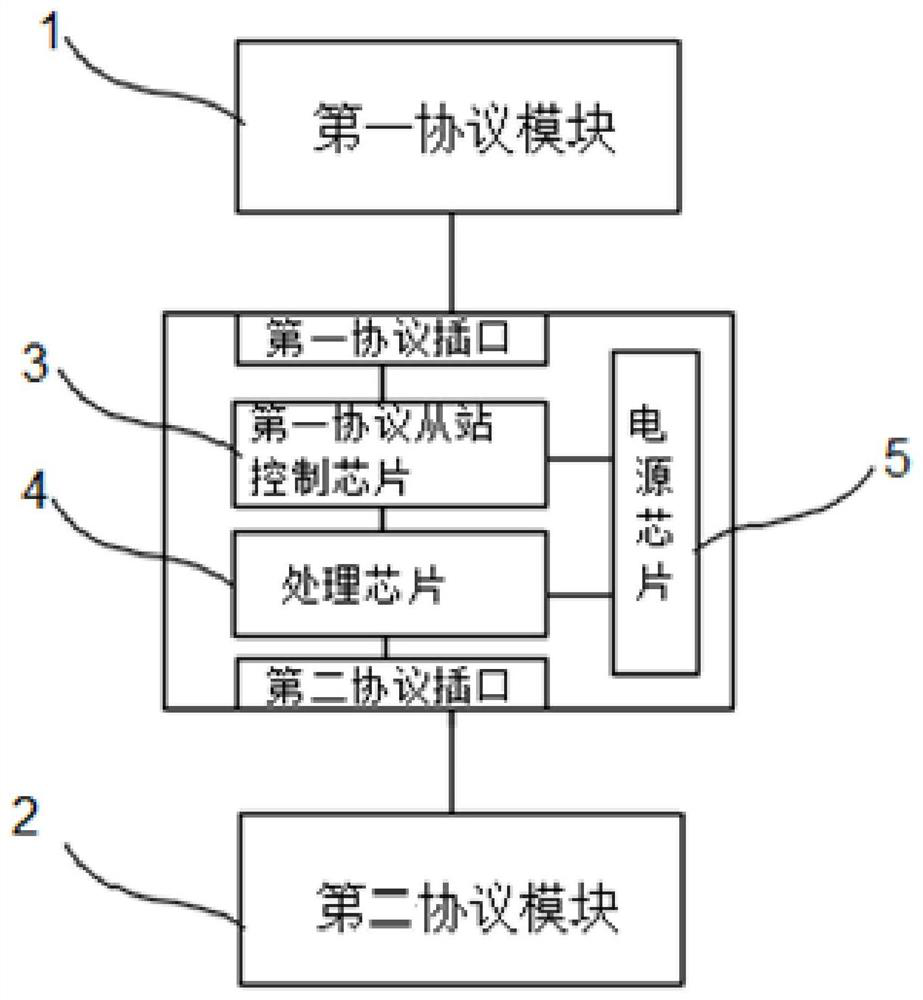

[0041] See attached Figure 1-2 As shown, a protocol conversion module between a robot and welding equipment of the present invention is applied between the first protocol module 1 and the second protocol module 2, the first protocol module 1 is located on the robot, and the second protocol module Module 2 is located on the welding equipment. The protocol conversion module includes a housing, the housing is provided with a first protocol slave control chip 3, a processing chip 4 fixed on the circuit board and a power supply for the first protocol slave control chip 3, the processing chip 5 Chip 5, the first protocol slave station control chip 3 communicates with the first protocol module 1 through the first bus through the housing, and the processing chip 4 receives the first language data transmitted by the first protocol slave station control chip 3 And analyze it into the second language data and transmit it to the second protocol module 2, and the processing chip 4 commun...

Embodiment 2

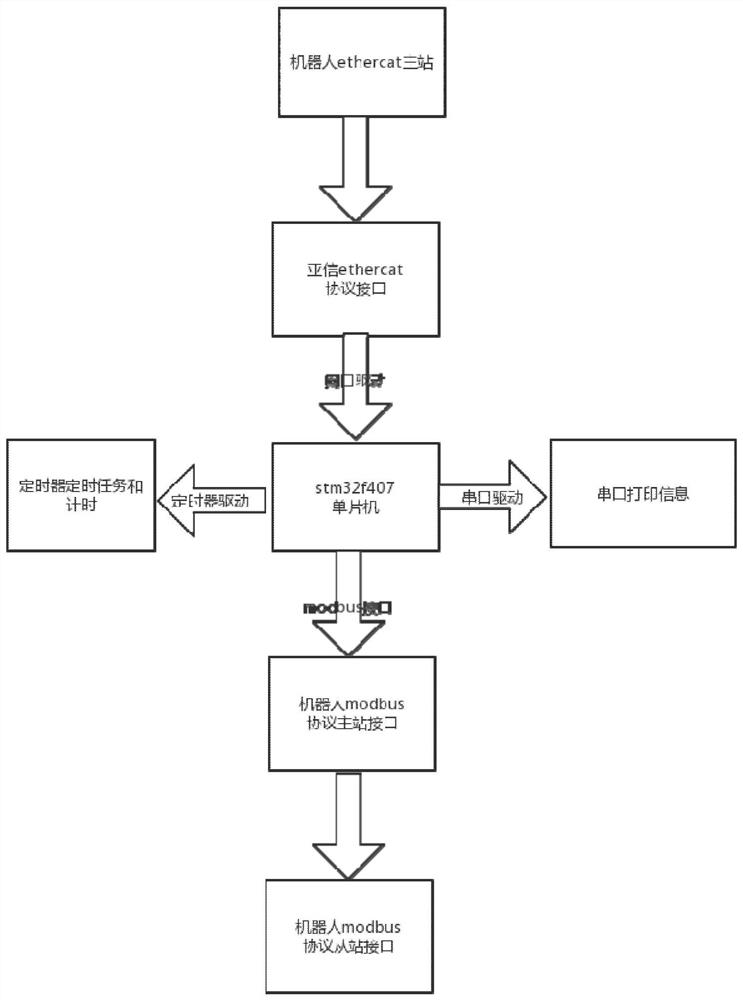

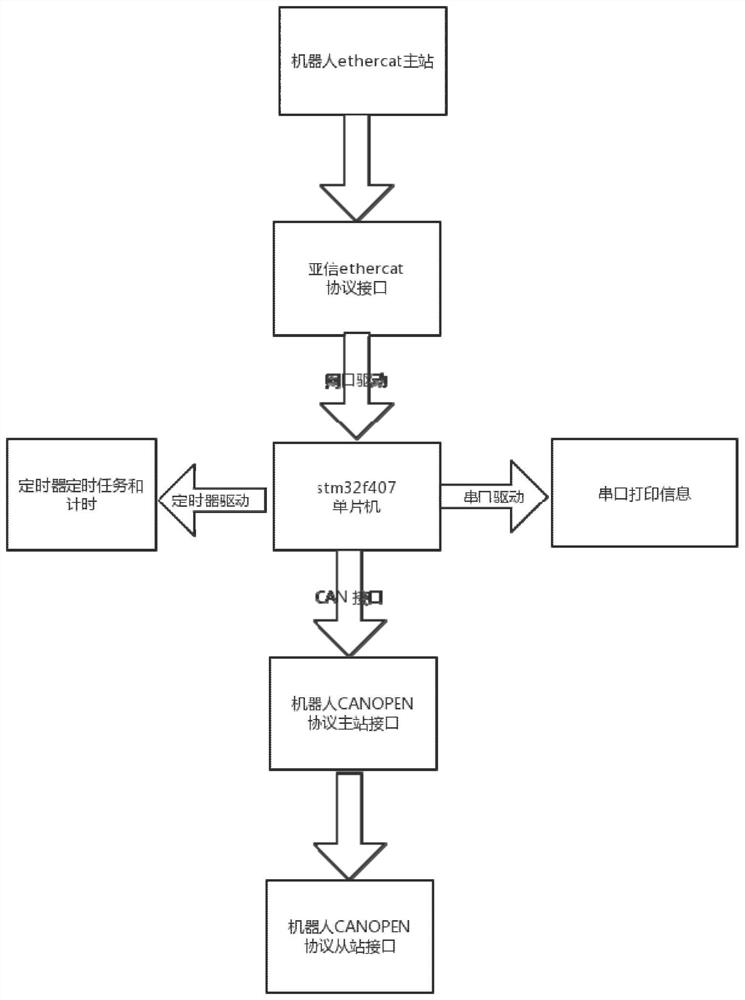

[0046] See attached image 3 , the first protocol module is an ethercat protocol module, the second protocol module is a canopen protocol module or a modbus protocol module, and the first protocol slave station control chip includes the AsiaInfo ax5800 chip using the ethercat protocol, and the AsiaInfo ax5800 chip It is used to receive the ethercat protocol instructions transmitted by the ethercat protocol module and transmit them to the processing chip. The processing chip is used to convert the transmitted ethercat protocol instructions into corresponding canopen protocol instructions, and communicate with the CAN transceiver set in the housing. Second bus connection, electrical schematic diagram of CAN transceiver see attached Figure 9 . Implement ethercat protocol to canopen protocol.

Embodiment 3

[0048] See attached Figure 4 , the first protocol module is a profibus protocol module, the second protocol module is an ethercat protocol module, and the first protocol slave station control chip includes a Hilscher netTAP100 chip. For the electrical schematic diagram of the Hilscher netTAP100 chip, see the attached Figure 10 , the Hilscher netTAP100 chip is used to receive the profibus protocol instructions transmitted by the profibus protocol module and transmit them to the processing chip, and the processing chip is used to convert the transmitted profibus protocol instructions into corresponding ethercat protocol instructions, and set The second RS485 transceiver in the casing is connected to the second bus, and the electrical distance diagram of the second RS485 transceiver is shown in the attachment Figure 11 . Realize profibus protocol to ethercat protocol.

[0049] The invention also discloses a conversion method of the protocol conversion module between the robo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com