Overhead-line-type carrier

A carrier and wire-type technology, applied in the field of wire-type carriers, can solve problems such as danger, application of force, wood movement, etc., and achieve excellent safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

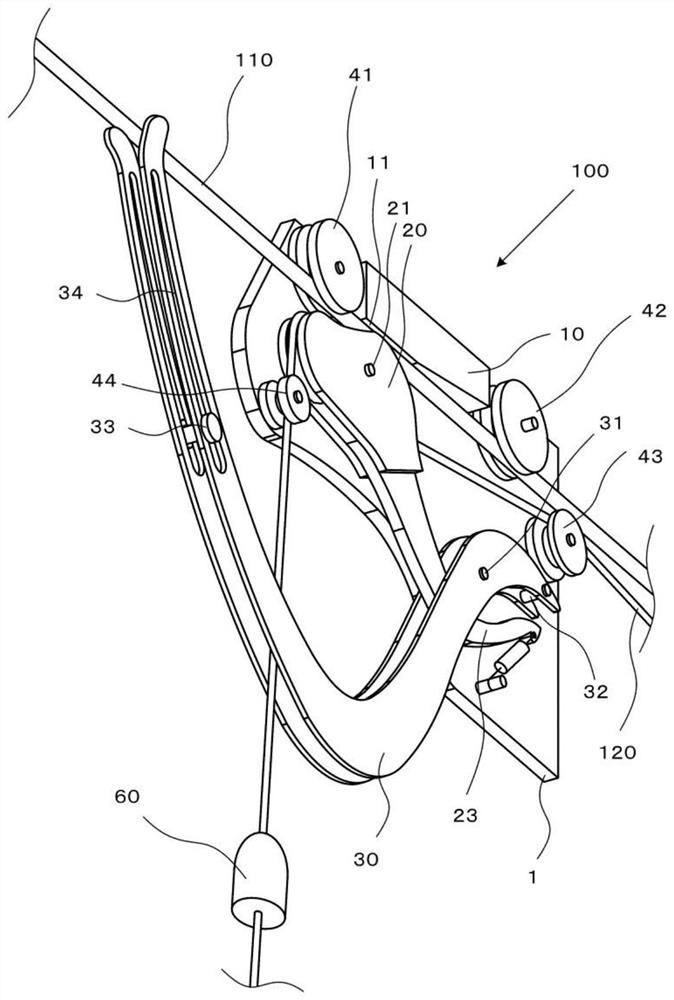

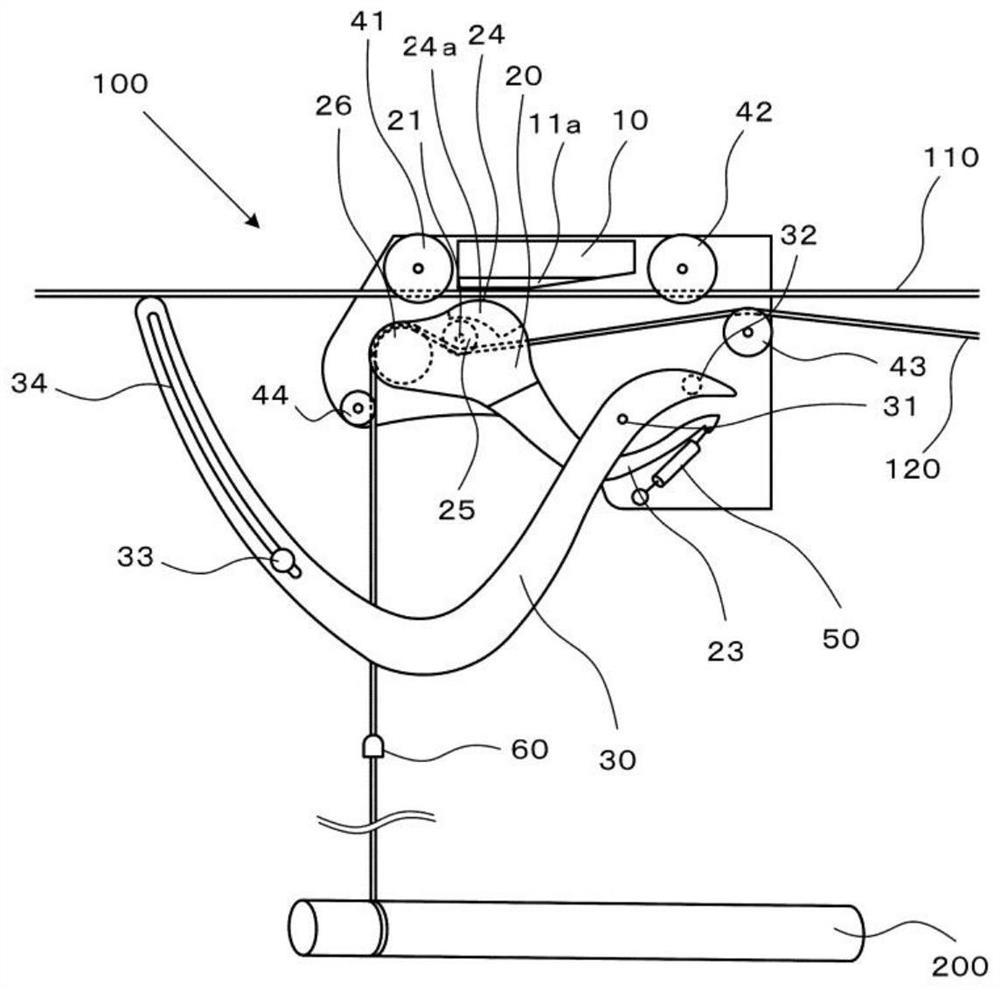

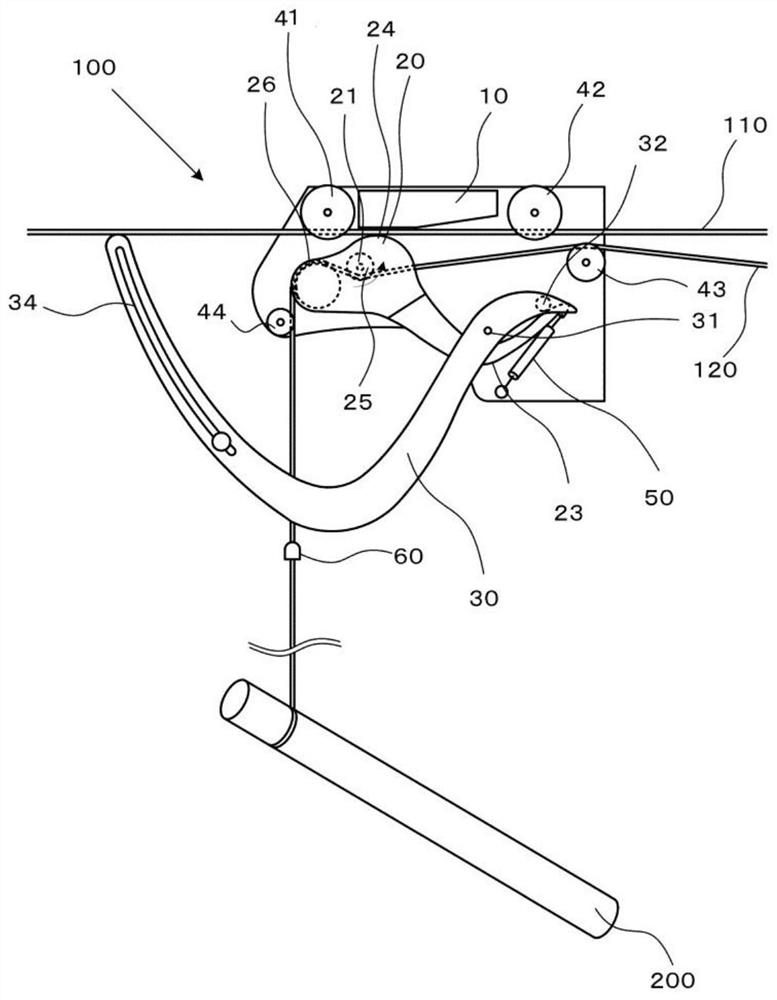

[0039] Next, the wire carrier 100 of the present invention will be described in detail with reference to the accompanying drawings. figure 1 It is a perspective view of the wire carrier 100 of this embodiment, figure 2 It is a front view of the wire carrier 100 of this embodiment.

[0040] The wire carrier 100 of the present invention uses a wire consisting of a main cable 110 for suspending the wire carrier 100 and a moving cable 120 for moving the wire carrier 100, and is used to control the movement of a single unit using a single winch. type carrier. The wire carrier 100 is particularly suitable for collecting felled logs as goods through ground traction.

[0041] Such as figure 1 As shown, the wire carrier 100 of the present invention mainly includes: a base part 1; a main cable braking part 10 installed on the base part 1; The first lever 20 of the moving part 10; the second lever 30 that moves the first lever 20 through the trigger 60 installed on the moving cable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com