Two-dimensional motion mixer

A two-dimensional motion and mixer technology, which is applied in the direction of mixers, transportation and packaging, mixer accessories, etc., can solve the problems that the production efficiency of two-dimensional motion mixers cannot meet the planned requirements, so as to improve the mixing effect, ensure stability, The effect of speeding up the mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

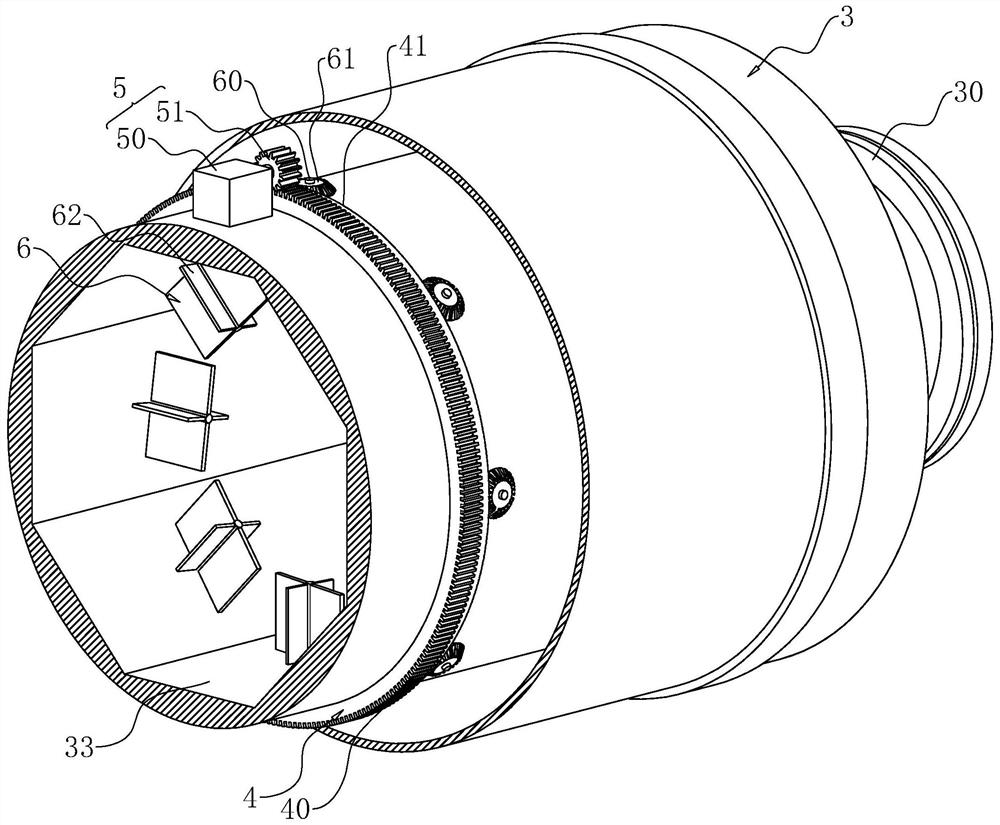

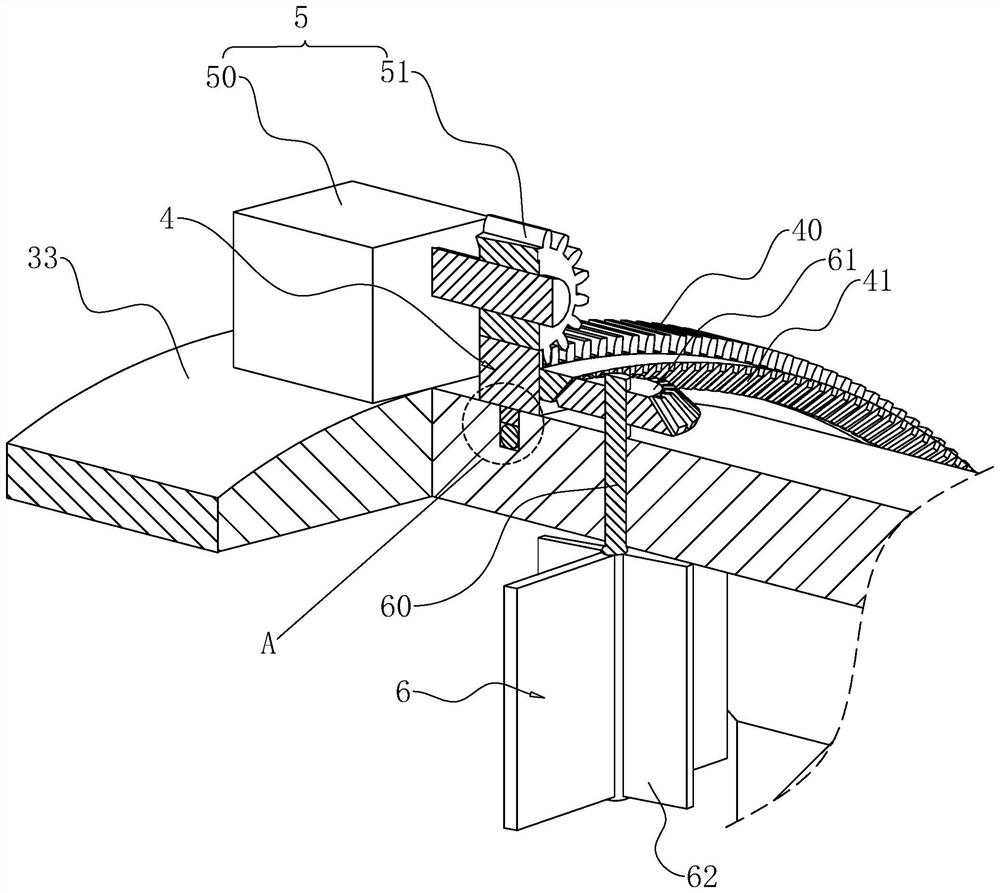

[0032] The following is attached Figure 1-4 The application is described in further detail.

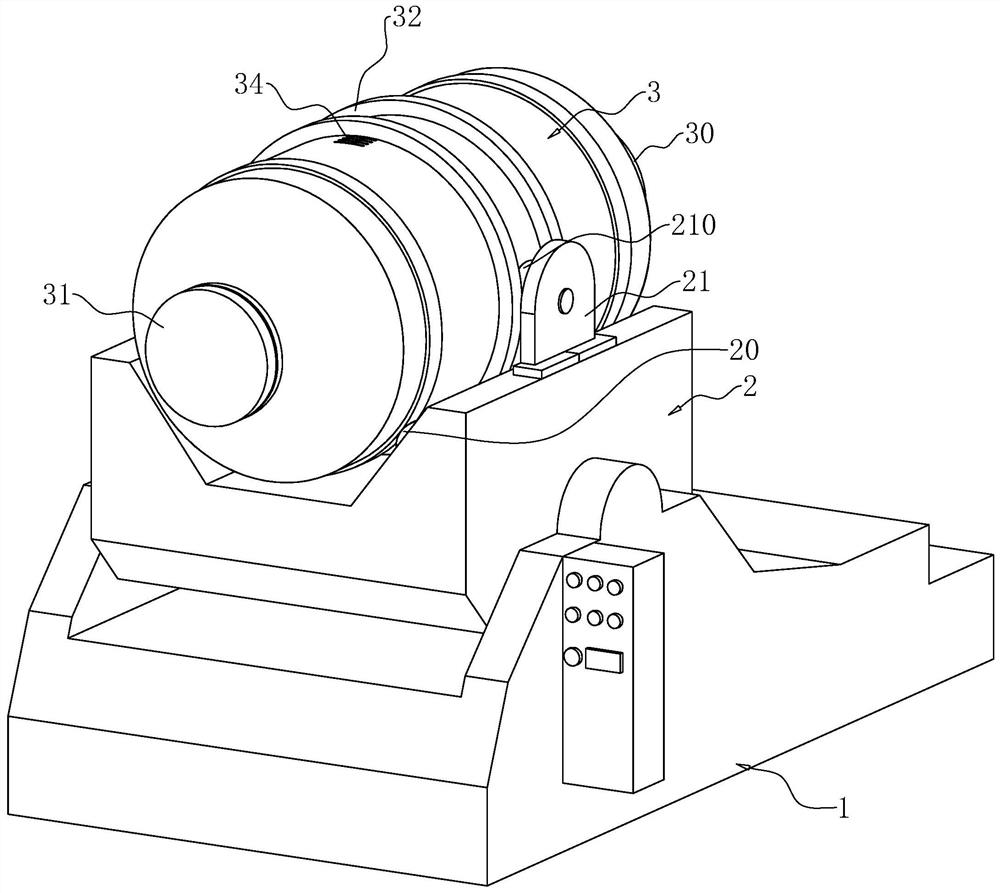

[0033] The embodiment of the present application discloses a two-dimensional motion mixer. refer to figure 1 , the two-dimensional motion mixer includes a frame 1, a swing frame 2 is installed on the frame 1, a drum 3 is arranged above the swing frame 2, and four supports for supporting the drum 3 are installed on the swing frame 2 The roller 20 is provided with a rotating power system for driving the two supporting rollers 20 to rotate in the swing frame 2, and a crank swing rod system for driving the swing frame 2 to swing in the frame 1, where the rotating power system is a two-dimensional motion hybrid The system commonly used in the machine, such as using a motor drive, the crank swing rod system also adopts a conventional structure, which will not be repeated here; two support seats 21 are fixed on the swing frame 2, and the two support seats 21 are respectively located on th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap