Amphibious vehicle and bottom plate compensation and trim adjustment device thereof

A trim adjustment, amphibious technology, applied to amphibious vehicles, motor vehicles, transportation and packaging, etc., can solve the problems of resistance and sailing stability, insufficient drag reduction effect, high weight density of amphibious vehicles, etc., to increase Sailing stability, drag reduction and energy saving effects are obvious, and the effect of improving vehicle navigation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

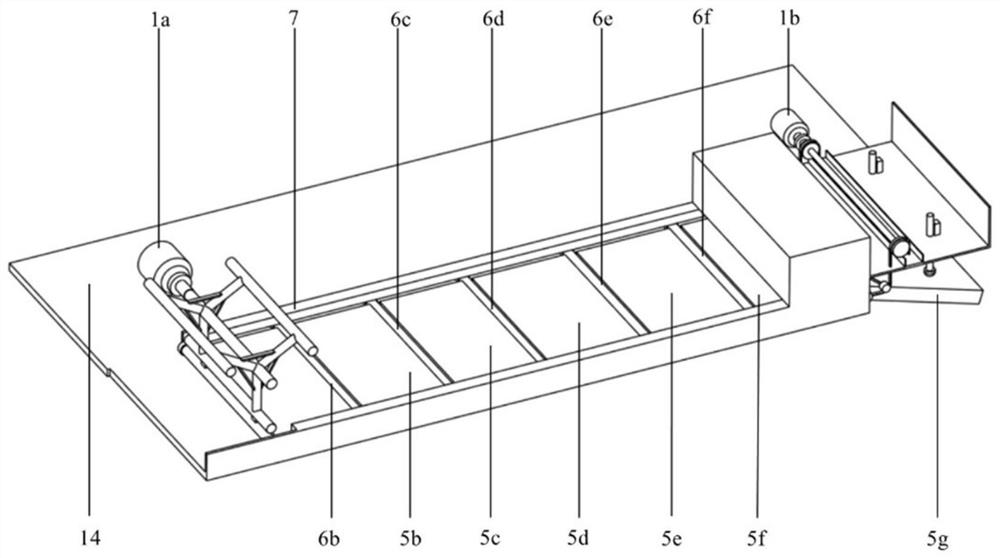

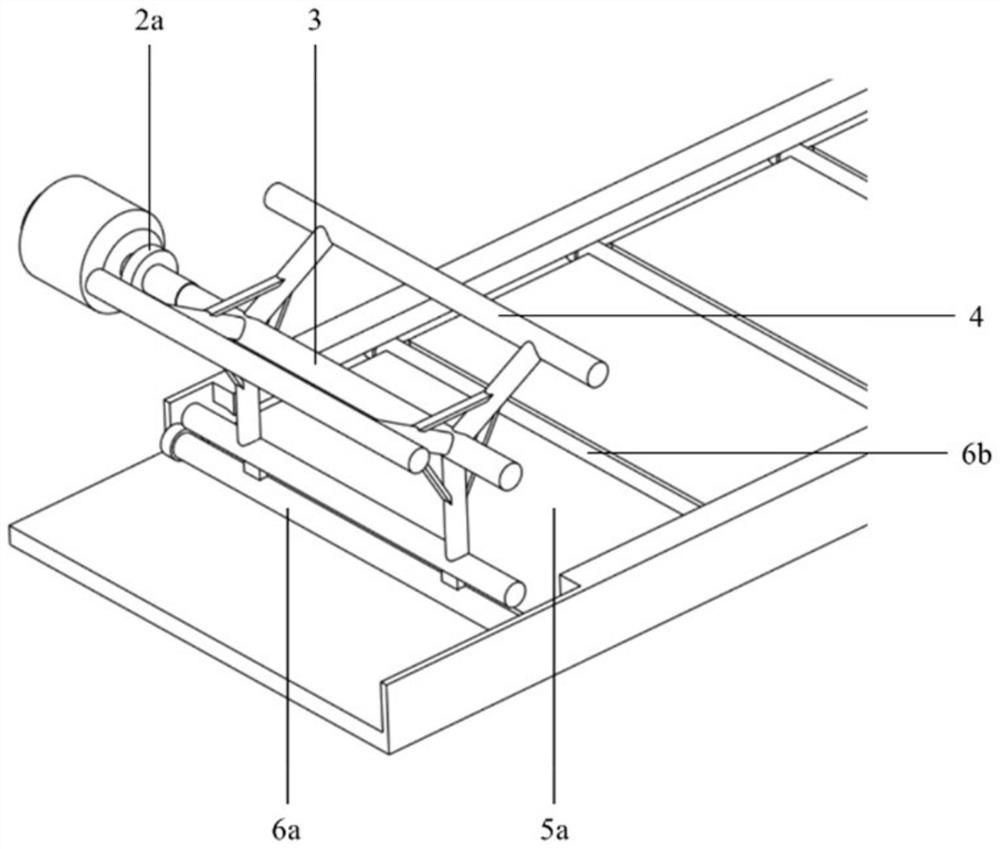

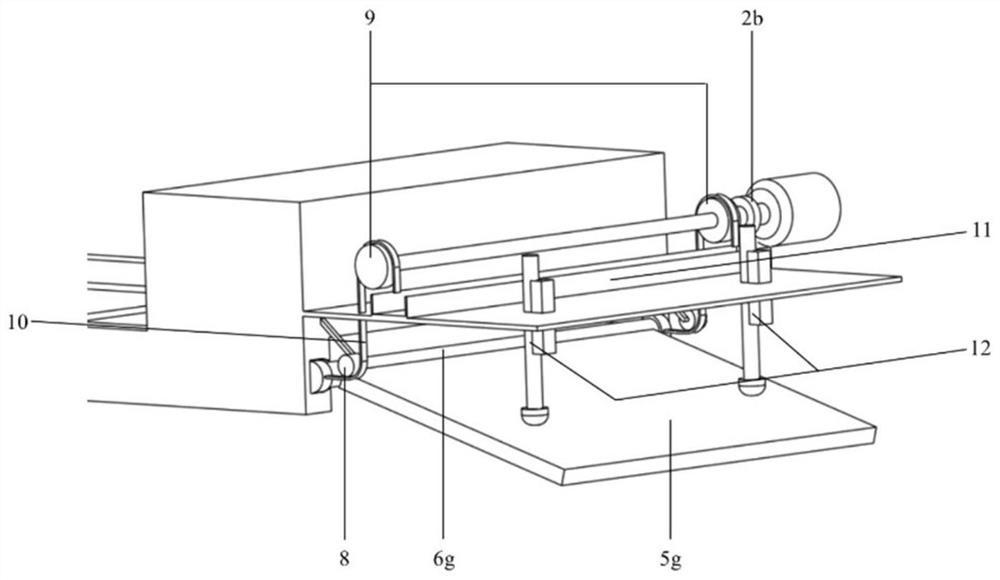

[0035] Such as figure 1 As shown, the floor compensation and pitch adjustment device of the amphibious vehicle of the present invention mainly includes a guide rail 7, a panel unit recovery structure, a panel unit pull-out and reception, a pitch adjustment structure and an integrated controller.

[0036] The guide rails 7 are arranged in two, parallel to each other, respectively located on both sides of the bottom of the rear wheel of the vehicle, arranged close to the bottom surface of the vehicle floor 14, and the front ends of the guide rails 7 extend to the inside of the main vehicle body 17, ensuring that the vehicle floor 14 at this position is compensated. The end of the guide rail 7 is set as a semi-closed structure, allowing the chain 10 to pass through while preventing the No. 7 plate unit connecting shaft 6g from slipping out. Between the two guide rails 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com