Magnetic levitation vehicle highway transportation method

A road transportation and vehicle technology, applied in the field of rail vehicles, can solve the problems of high input cost, high professional requirements, and unnecessary resources, etc., and achieve the effect of low input cost, low professional requirements, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment provides a road transport method for maglev vehicles, the specific method is as follows:

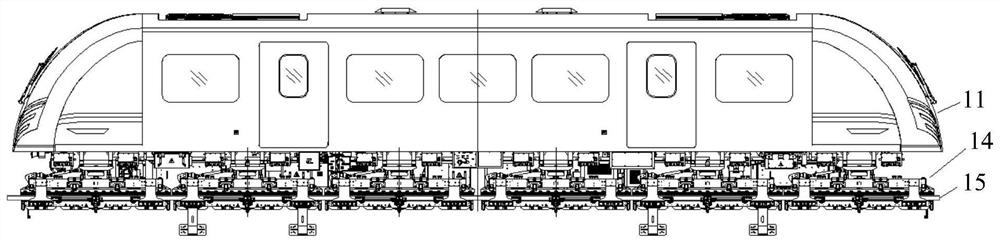

[0047] S1. Disassemble the maglev vehicle into two parts, the suspension vehicle body and the suspension frame, for road transportation respectively;

[0048] S2. Install a plurality of support toolings on the car body side beams at the bottom of the suspended car body; hoist them together with the support tooling and the suspended car body onto the platform of the transport vehicle, and the suspended vehicle body contacts the platform of the transport vehicle through the support tooling.

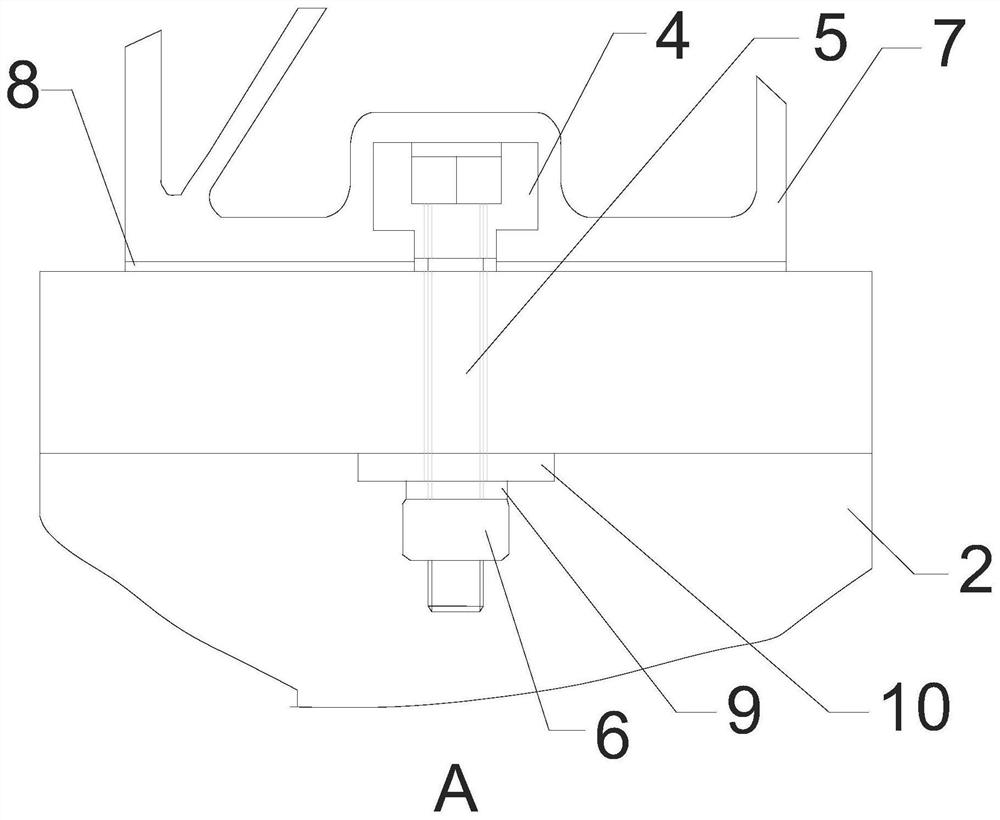

[0049] Use four steel structure support tooling to fix bolts to the side beam chute of the car body according to a certain size interval, and then hoist them together with the support tooling and the car body to the platform of the transport vehicle. Use a pull belt with a certain load to indirectly tie and fix the car body and the transport vehicle together through the support ...

Embodiment 2

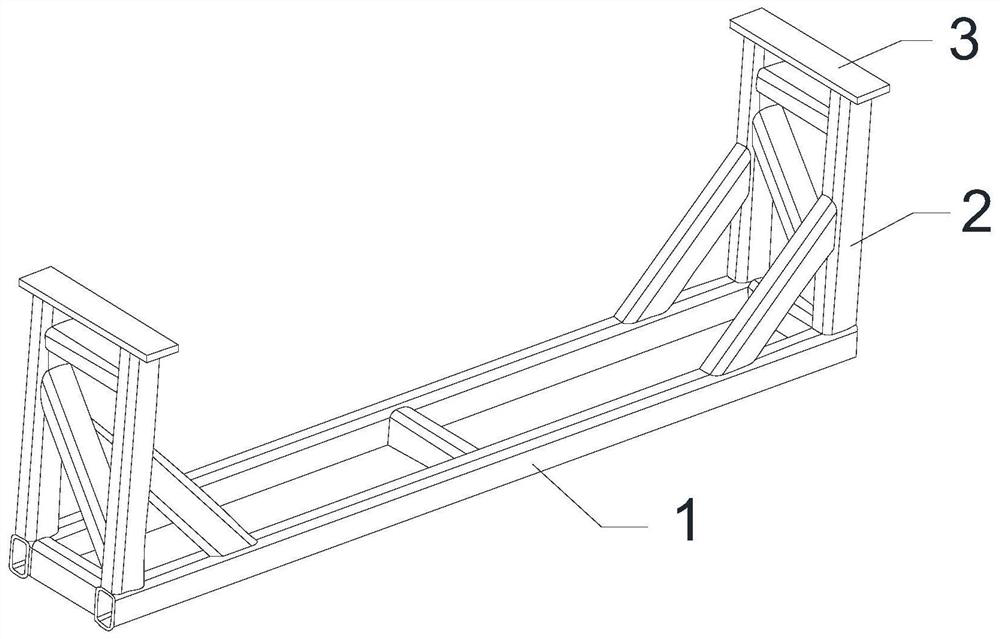

[0052] This embodiment provides a transport support tooling, such as figure 2 As shown, in a road transportation method for a maglev vehicle provided in Embodiment 1, it is used to realize the support for the suspension vehicle body in step S2.

[0053] The whole is made of Q345B material, and the specific structure includes a base 1 and two sets of support frames 2, and the two sets of support frames 2 are installed on both sides of the base 1. The base 1 and / or the support frame 2 is a frame structure formed by welding square steel, specifically: the base 1 is composed of two cross bars, the two cross bars are arranged parallel to each other in the axial direction, and are connected as an integral structure by three connecting rods; The sets of support frames 2 are installed on the axial ends of the cross bars; each set of support frames 2 is composed of two vertical bars, the bottom ends of the two vertical bars are respectively fixed on the corresponding horizontal bars, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com