Cloth rolling device for garment production

A technology for fabrics and garments, applied in the field of fabric rolling devices for garment production, can solve problems such as errors, inconvenience in removing fabrics, and consistent lengths of reeled fabrics, so as to achieve good rewinding work, maintain rewinding lengths, and maintain consistency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

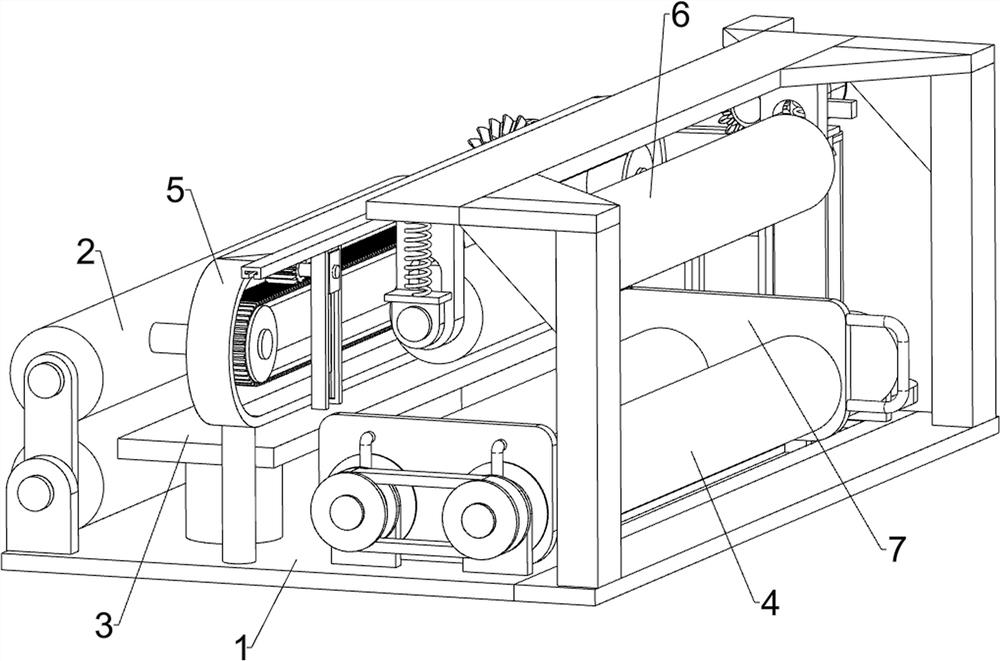

[0026] A cloth rolling device for garment production, such as Figure 1-7 As shown in the figure, it includes a bottom plate 1, a limit roller 2, a spreading platen 3, a rolling mechanism 4 and a cutting mechanism 5. The top left side of the bottom plate 1 is rotatably connected with two limit rollers 2. The two limit The rotating roller 2 is symmetrical up and down, the top of the bottom plate 1 is connected with a cloth spreading platen 3, the cloth spreading platen 3 is located on the right side of the limit rotating roller 2, and the top of the bottom plate 1 is respectively equipped with a rolling mechanism 4 and a cutting mechanism 5.

[0027] The winding mechanism 4 includes a first drum 41 , a second drum 42 , a first transmission belt group 43 , a fixed baffle 44 , a second transmission belt group 45 , a mounting plate 46 , a first bevel gear 47 , and a double-head bevel gear 48 and servo motor 49, a fixed baffle 44 is connected to the top right front side of the bott...

Embodiment 2

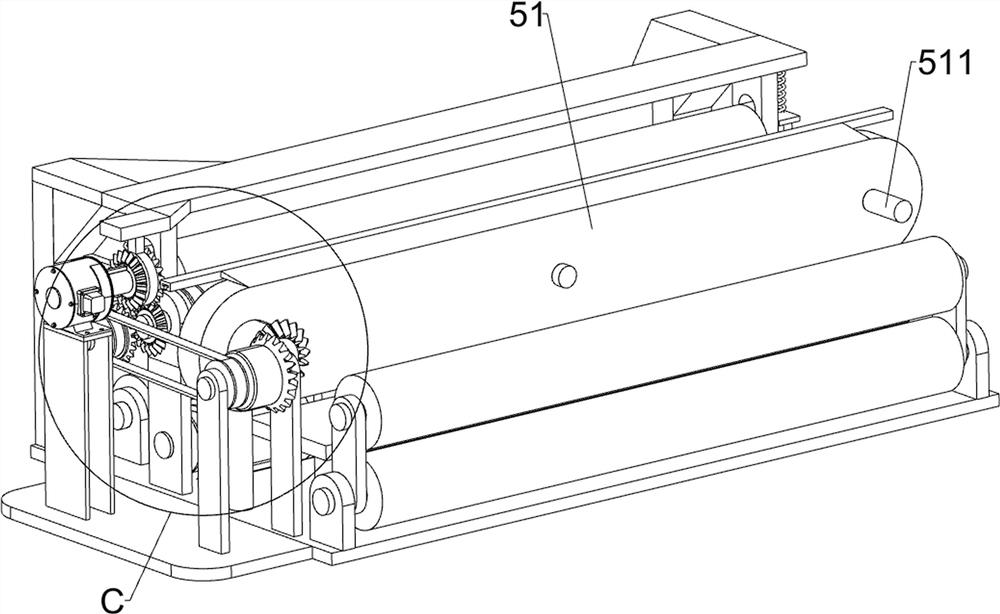

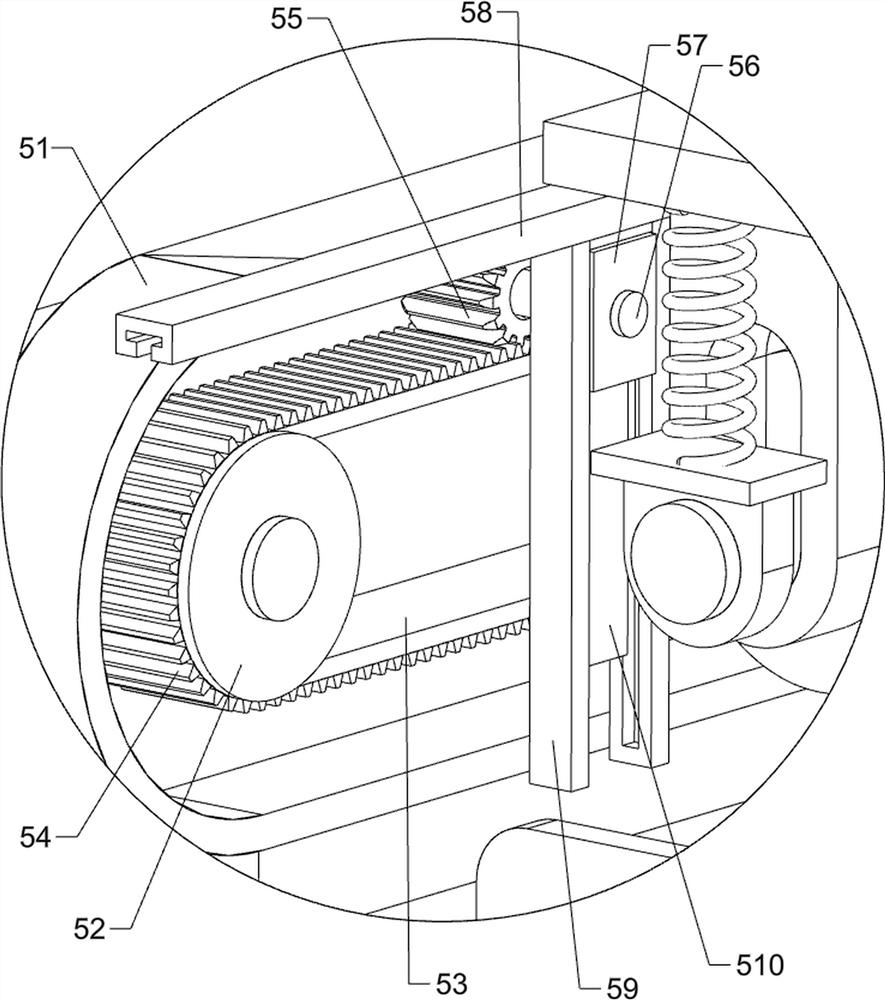

[0031] On the basis of Example 1, as figure 1 , figure 2 , image 3 , Figure 5 and Figure 7As shown, a trigger mechanism 6 is also included. The trigger mechanism 6 includes a mounting frame 61, a sliding roller 62, a guide block 63, a connecting block 64, a support spring 65, a wedge push rod 66, a sliding collar 67, and a second bevel gear. 68. The third drive belt set 69, the third bevel gear 610, the fourth bevel gear 611 and the fixing frame 612, the mounting frame 61 is connected to the right side of the top of the bottom plate 1, and the front and rear sides of the inner top of the mounting frame 61 are connected with guide blocks 63, a connecting block 64 is slidably connected between the two guide blocks 63, a sliding roller 62 is rotatably connected in the middle of the connecting block 64, and two supporting springs 65 are connected between the top of the connecting block 64 and the inner top of the mounting frame 61, The two support springs 65 are symmetrica...

Embodiment 3

[0034] On the basis of Example 2, as figure 1 As shown, it also includes a width adjustment plate 7, the top right side of the bottom plate 1 is slidably connected with the width adjustment plate 7, and the width adjustment plate 7 is slidably and rotatably connected with the first roller 41 and the second roller 42.

[0035] The width adjustment plate 7 can be moved so that the width adjustment plate 7 is in contact with the reel, so that the reel can better perform the cloth winding work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com