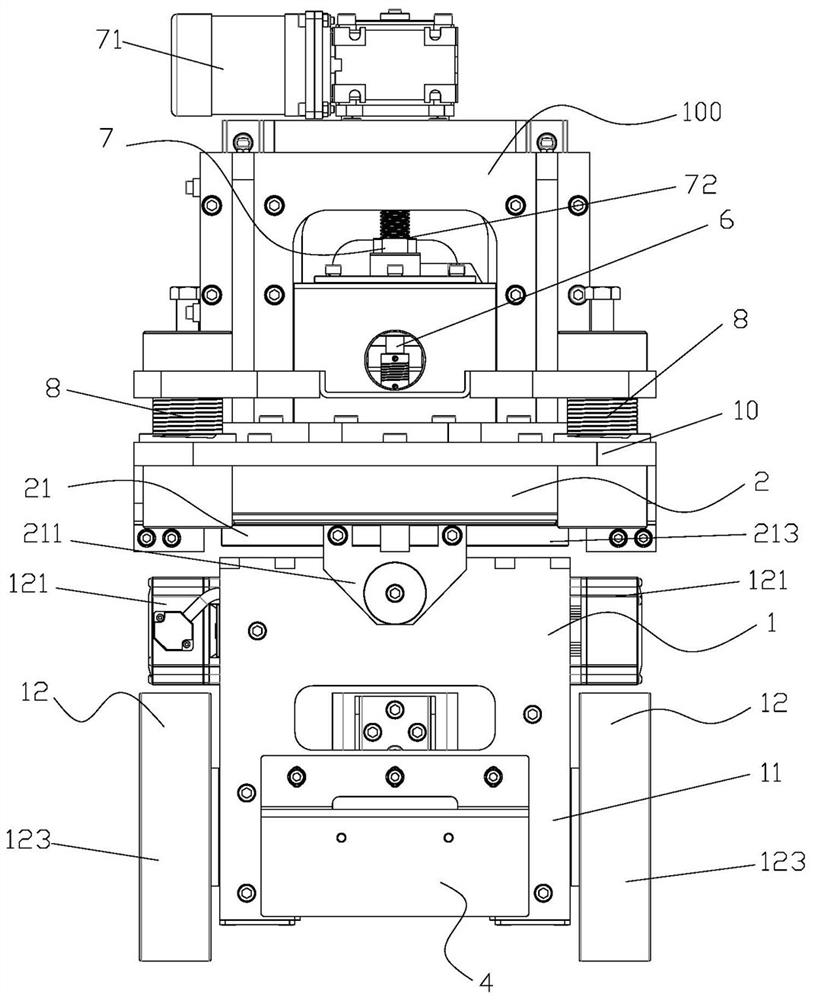

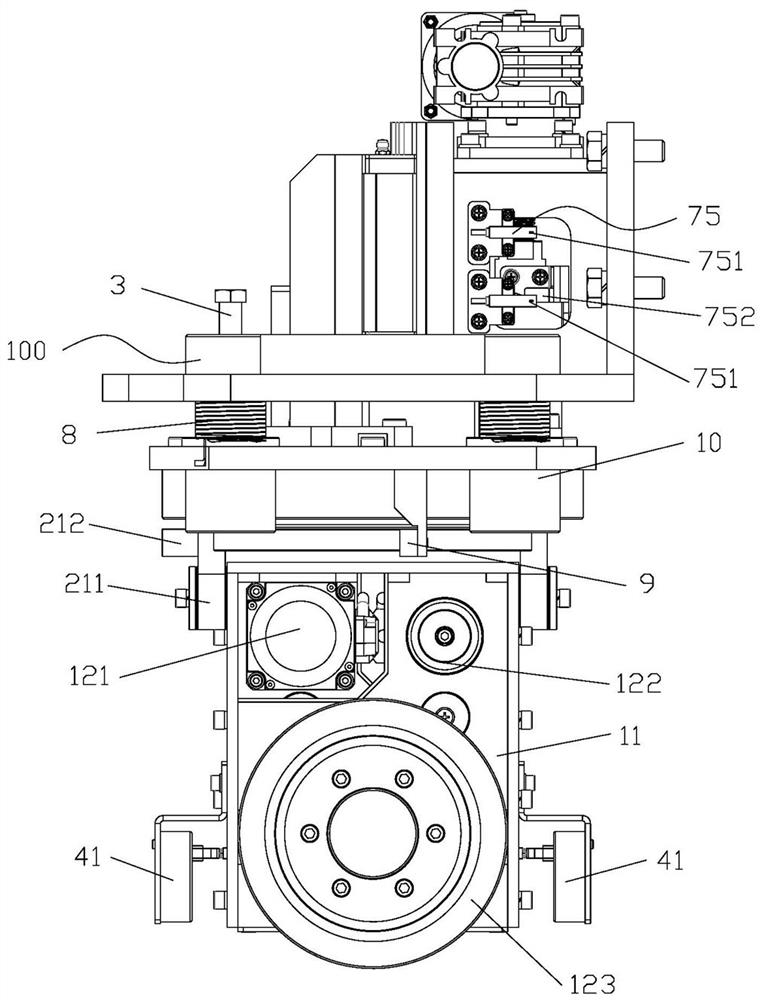

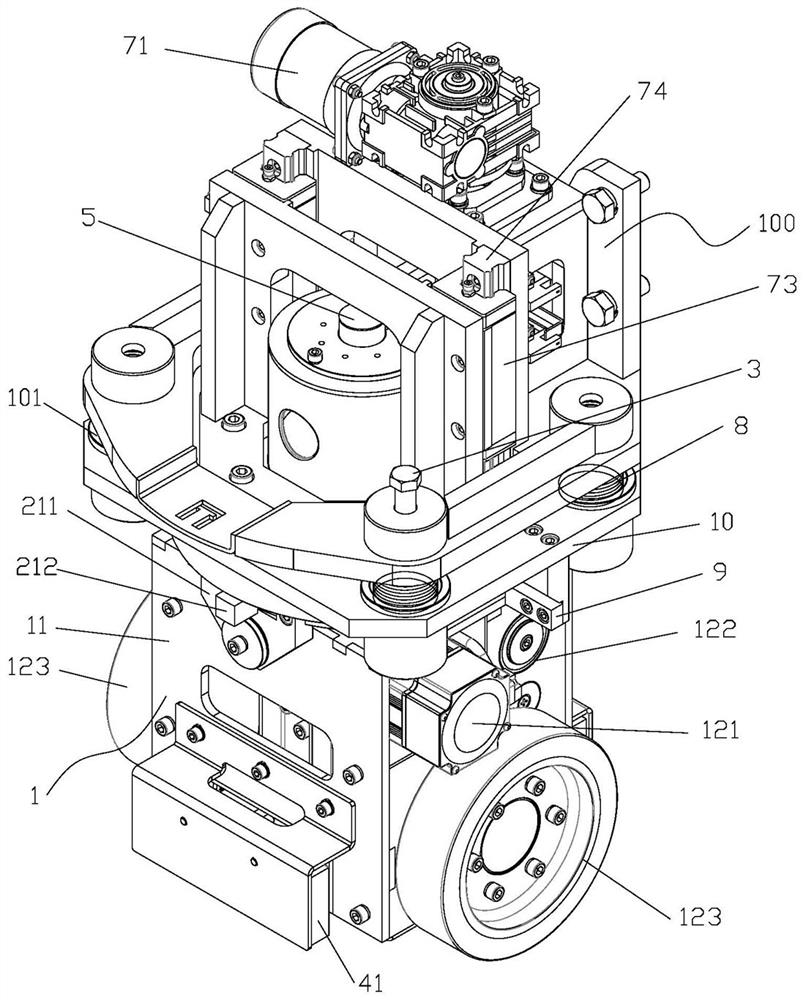

A vertical differential drive assembly

A differential drive and assembly technology, applied in the direction of lifting devices, etc., can solve the problems of inconvenient forklift switching work sites, difficulty in setting up driving and lifting devices, unfavorable magnetic navigation sensor layout, etc., to achieve convenient switching of work sites and ground pressure Large, strong anti-interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following detailed description provides various embodiments or examples for implementing the invention. Of course, these are merely embodiments or examples and are not intended to be limiting. In addition, repeated reference numerals, such as repeated numbers and / or letters, may be used in different embodiments. These repetitions are for the purpose of simply and clearly describing the present invention, and do not represent any specific relationship between the different embodiments and / or structures discussed.

[0032] In addition, terms related to space may be used, such as "below", "underside", "inside out", "above", "upper side" and similar terms, these relative words In order to facilitate the description of the relationship between one (some) elements or features and another (some) elements or features in the drawings, these spatial relative terms include different orientations of the device in use or operation, as well as the position. The device may be t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com