High-moisture-barrier colorless transparent polyimide composite film and preparation method thereof

A technology of transparent polyimide and polyimide base film, applied in the field of polyimide film, can solve the problems of insufficient flexibility of CPI-glass composite film, insufficient barrier property and hardness of CPI film, etc. The effect of excellent bendable and foldable mechanical properties, high hardness and high water vapor barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

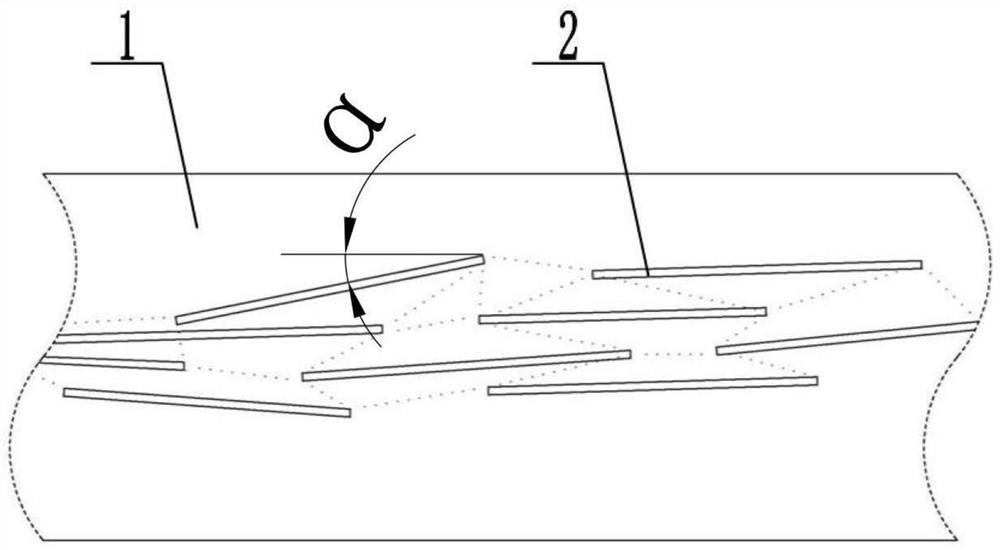

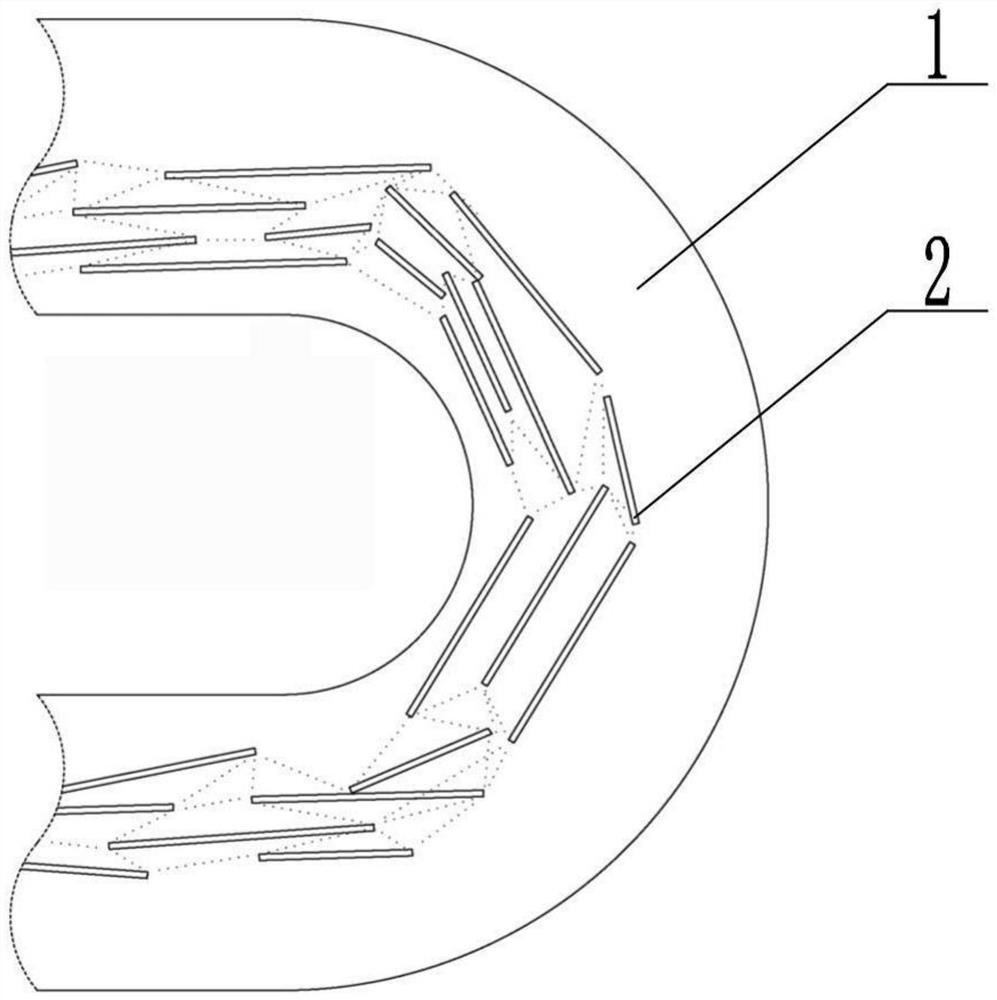

[0033] A high water vapor barrier colorless transparent polyimide composite film, comprising polyimide base film 1, glass microchip 2, said polyimide base film 1 is made of polyamic acid precursor or polyimide The solution is solidified and formed, and also includes an organic filler, and the organic filler is dispersed in the polyimide base film 1, and the polyimide base film 1 wraps the glass microchip 2, and the glass microchip The angle between 2 and the plane of the polyimide base film 1 is α, 0°≤α≤30°, the thickness of the polyimide base film 1 is 15 μm, and the thickness of the glass microchip 2 The diameter of the glass microchip 2 is 1 μm, and the volume ratio of the polyimide base film 1 to the glass microchip 2 is 1:0.05.

[0034] Preferably, the edge of the glass microchip 2 has a cross-linkable group.

[0035] Preferably, the glass microchips 2 are connected to each other through the crosslinkable groups.

[0036] Preferably, the organic filler is a dispersant, ...

Embodiment 2

[0045]A high water vapor barrier colorless transparent polyimide composite film, comprising polyimide base film 1, glass microchip 2, said polyimide base film 1 is made of polyamic acid precursor or polyimide The solution is solidified and formed, and also includes an organic filler, and the organic filler is dispersed in the polyimide base film 1, and the polyimide base film 1 wraps the glass microchip 2, and the glass microchip The angle between 2 and the plane of the polyimide base film 1 is α, 0°≤α≤30°, the thickness of the polyimide base film 1 is 200 μm, and the thickness of the glass microchip 2 The diameter of the glass microchip 2 is 150 μm, and the volume ratio of the polyimide base film 1 to the glass microchip 2 is 0.25:1.

[0046] Preferably, the edge of the glass microchip 2 has a cross-linkable group.

[0047] Preferably, the glass microchips 2 are connected to each other through the crosslinkable groups.

[0048] Preferably, the organic filler is a dispersant...

Embodiment 3

[0057] A high water vapor barrier colorless transparent polyimide composite film, comprising polyimide base film 1, glass microchip 2, said polyimide base film 1 is made of polyamic acid precursor or polyimide The solution is solidified and formed, and also includes an organic filler, and the organic filler is dispersed in the polyimide base film 1, and the polyimide base film 1 wraps the glass microchip 2, and the glass microchip The angle between 2 and the plane of the polyimide base film 1 is α, 0°≤α≤30°, the thickness of the polyimide base film 1 is 100 μm, and the thickness of the glass microchip 2 The diameter of the glass microchip 2 is 70 μm, and the volume ratio of the polyimide base film 1 to the glass microchip 2 is 0.62:0.52.

[0058] Preferably, the edge of the glass microchip 2 has a cross-linkable group.

[0059] Preferably, the glass microchips 2 are connected to each other through the crosslinkable groups.

[0060] Preferably, the organic filler is a dispers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com