Intermittent circulating two-sided flipping high-efficiency printing and dyeing device

A circular, double-sided technology, applied in the processing of textile materials equipment configuration, textiles and papermaking, textile processing machine accessories, etc., can solve the problems of printing and dyeing purity and precision reduction, insufficient uniformity of fabric printing and dyeing, unfavorable energy-saving production, etc. To achieve the effect of sufficient power, fast speed and prevention of mutual influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

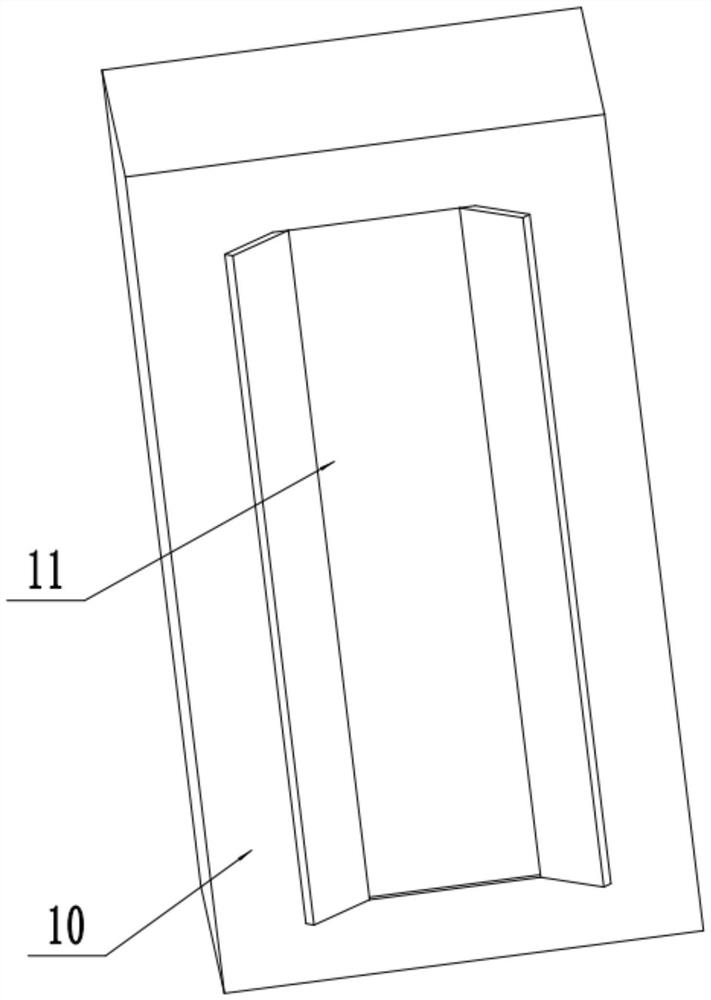

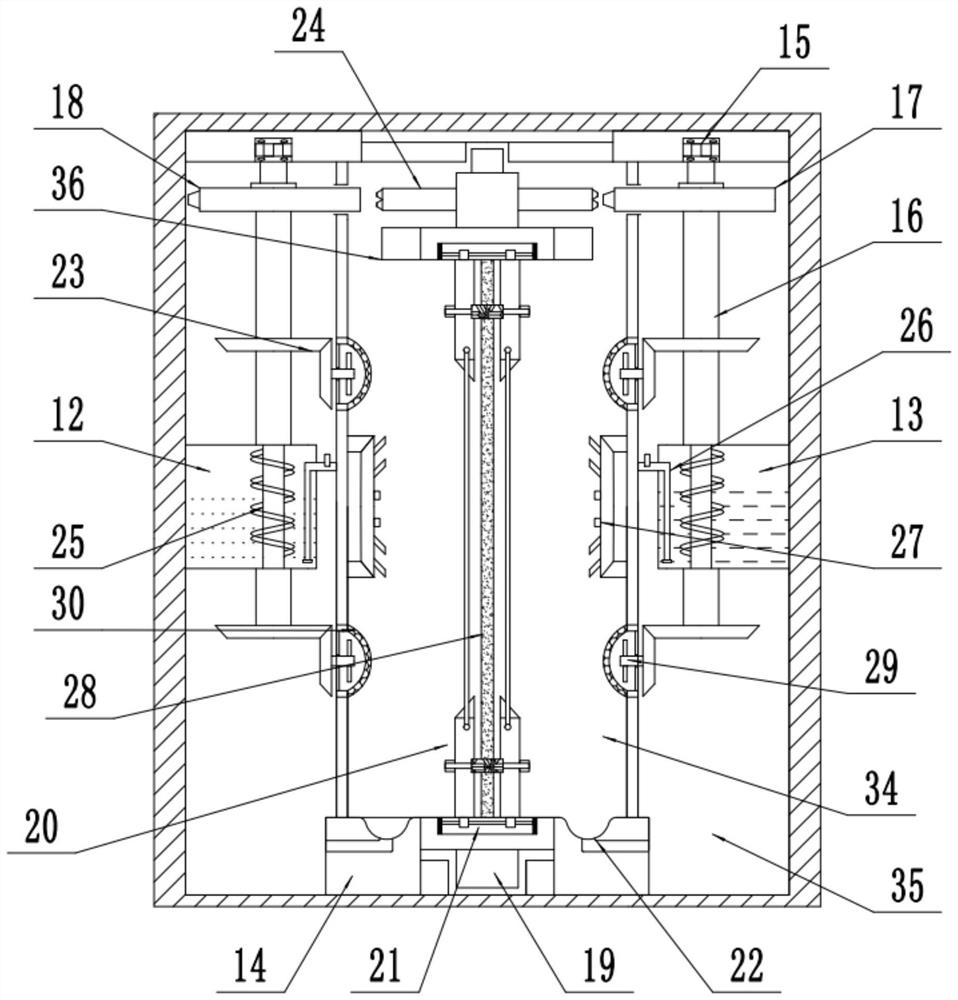

Embodiment 1

[0024] see Figure 1-4 , an intermittent cycle type double-sided flip high-efficiency printing and dyeing device, including a box body 10, the box body 10 is arranged in a rectangular structure and the front side of the box body 10 is hinged with a box door 11, through which the box door 11 is convenient for printing and dyeing. Clothing material 28 is placed inside the casing 10 . The inner middle part of the box body 10 is provided with a printing and dyeing chamber 34 with a cylindrical structure, and the left and right sides of the printing and dyeing chamber 34 are symmetrically provided with transmission chambers 35 respectively. There are two sets of fastening devices 20 for clamping and stabilizing the fabric 28 to be printed and dyed symmetrically on the upper and lower sides. The bottom of the side of the fastening device 20 away from the center of the box body 10 is provided with a rotating seat 36, and the rotating seat 36 faces the printing and dyeing chamber 34. ...

Embodiment 2

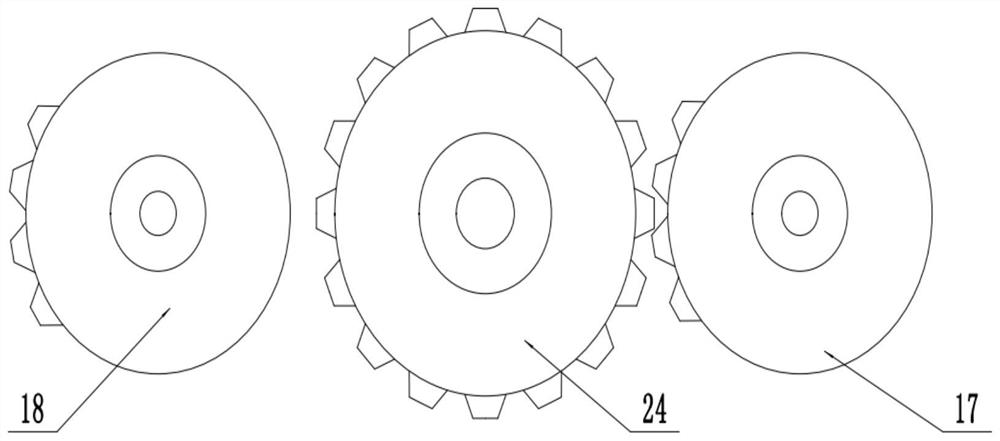

[0028]On the basis of Embodiment 1, a vertical transmission rod 16 is fixedly installed at the lower center of the first incomplete gear 17 and the second incomplete gear 18, and the transmission rod 16 passes through the first dye tank 12 downwards. And the inside of the second dye tank 13, the bottom and the top of the transmission rod 16 are fixedly equipped with a helical gear transmission mechanism 23 composed of two groups of vertical meshing helical gears, and the vertical segment helical gear of the helical gear transmission mechanism 23 rotates to the right through the bearing Connected in the side wall of the printing and dyeing chamber 34, the right side of the vertical segment helical gear is fixedly installed with a fan 29 placed inside the printing and dyeing chamber 34, and the outer side of the fan 29 is equipped with a protective cover 30 that is convenient for gas discharge and prevents impurities from entering. The rotation of the transmission rod 16 drives t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com