Replaceable anti-fatigue orthotropic plate structure and replacement method

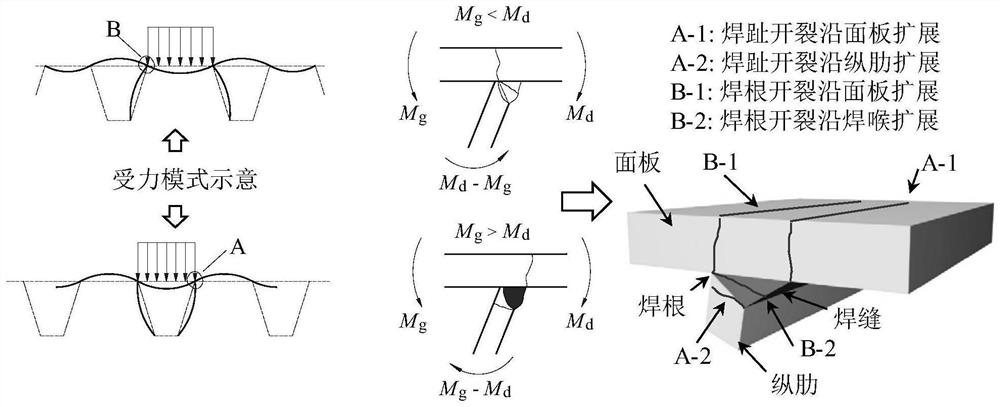

An anti-fatigue technology for orthotropic plates, applied to bridge parts, erection/assembly bridges, bridge materials, etc., can solve the problems of difficult repair of damage, fatigue damage of orthotropic plates, etc., and achieve the effect of avoiding fatigue damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing:

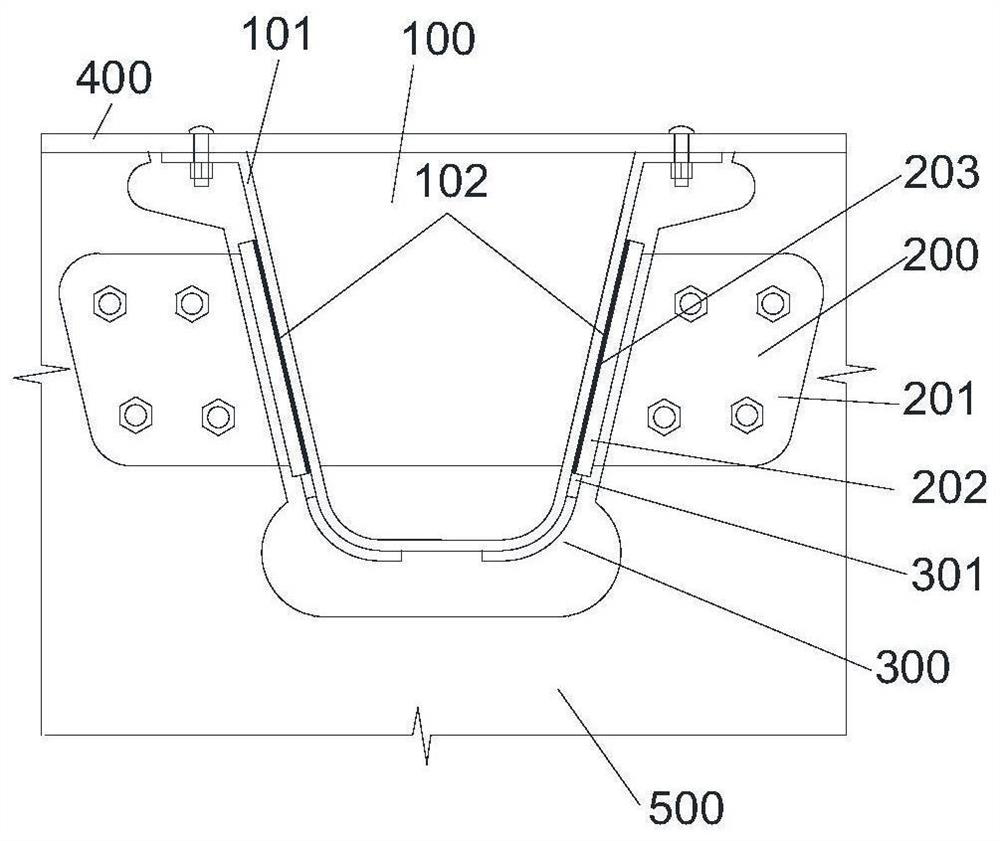

[0038] Such as image 3 As shown in , it is a schematic structural diagram of a replaceable anti-fatigue orthotropic plate structure.

[0039] The detachable anti-fatigue orthotropic plate structure of the present invention includes several U-rib assemblies 100 detachably arranged. The U-rib assemblies 100 include U-shaped ribs 101, and the two sides of the U-shaped ribs 101 are inclined edges. The upper end of the U-shaped rib 101 is fixedly connected to the top plate 400 by non-welding. Preferably, the connection manner between the U-shaped rib 101 and the top plate 400 includes bolt connection or riveting.

[0040] On the outer sides of both sides of the U-shaped rib 101, a receiving plate 102 is affixed, and the receiving plate 102 abuts against the oblique lateral limiting assembly 200. The connecting plate 201 is vertically provided with a limiting plate 202 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com