A kind of paint spraying system for wall surface and surface spraying method thereof

A technology for spraying surfaces and walls, which is applied to the paint spraying system on the wall surface and the field of surface spraying, which can solve the problems of high labor intensity, difficulty in spraying paint, and uneven spraying, so as to reduce labor intensity and improve spraying effect and spraying quality, the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

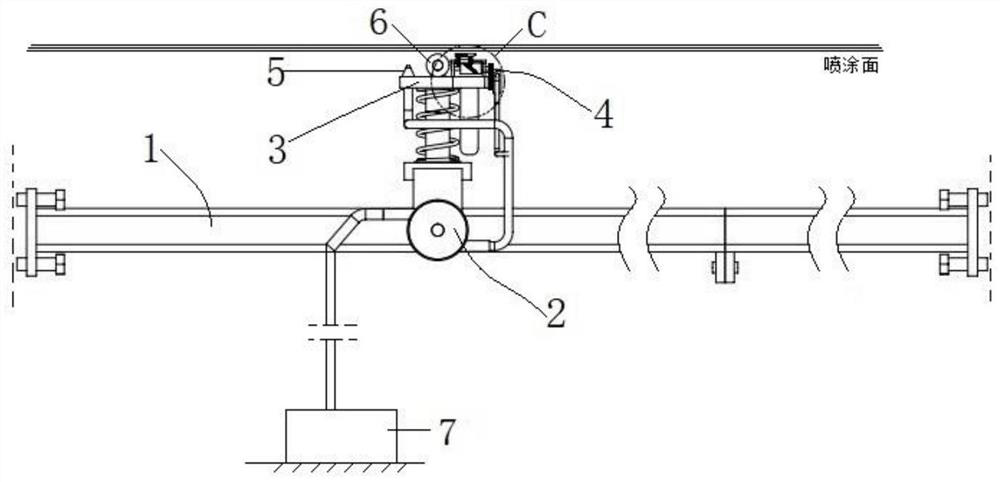

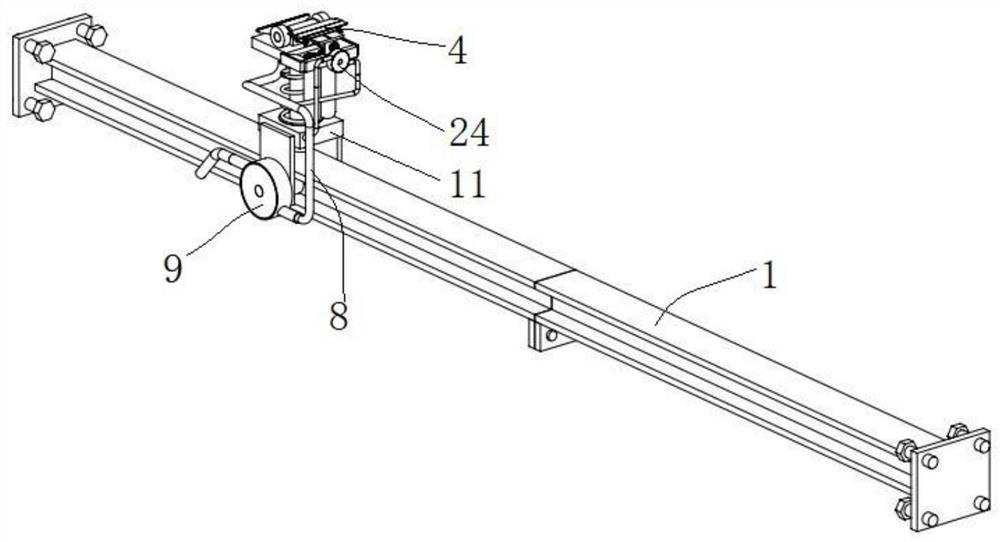

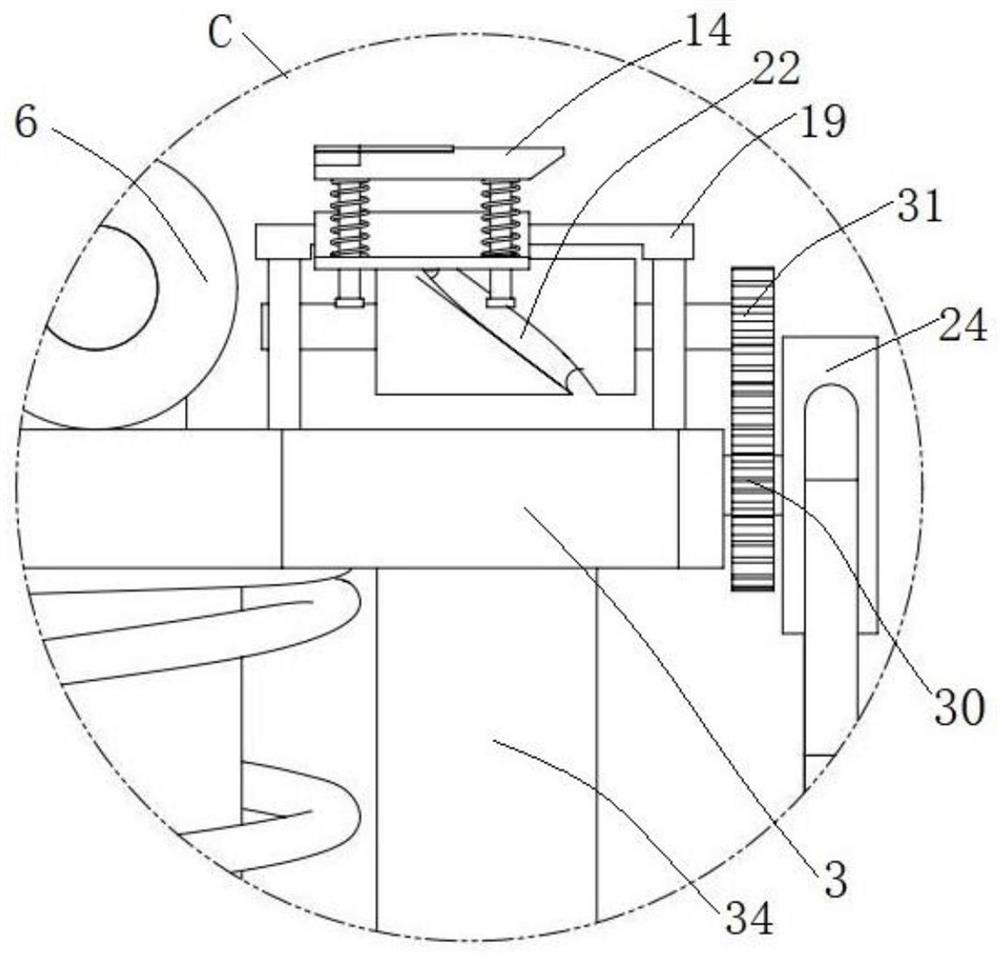

[0029] as attached figure 1 to the attached Figure 4 As shown, a paint spraying system for the surface of a wall includes a support rail 1, a displacement mechanism 2, a spraying mechanism, a support plate 3, a grinding mechanism 4 and a rolling wheel 6, and the support rail 1 is arranged at a parallel interval to be sprayed Below the top wall, the support rail 1 is an I-beam, and the displacement mechanism 2 is provided on the support rail 1 to move back and forth along the length direction. The displacement mechanism travels on the support rail to ensure spraying operation. The stability and the uniformity of spraying are improved, and the labor intensity of the operators is reduced. The displacement mechanism 2 is elastically provided with a support plate 3 in the direction perpendicular to the spray surface. The elastically arranged support plate 3 ensures the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com