General gear pair service life test board

A technology of life testing and gear pairs, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve problems such as restoration, achieve reliable life assessment, save measurement time, and have simple structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with drawings and embodiments.

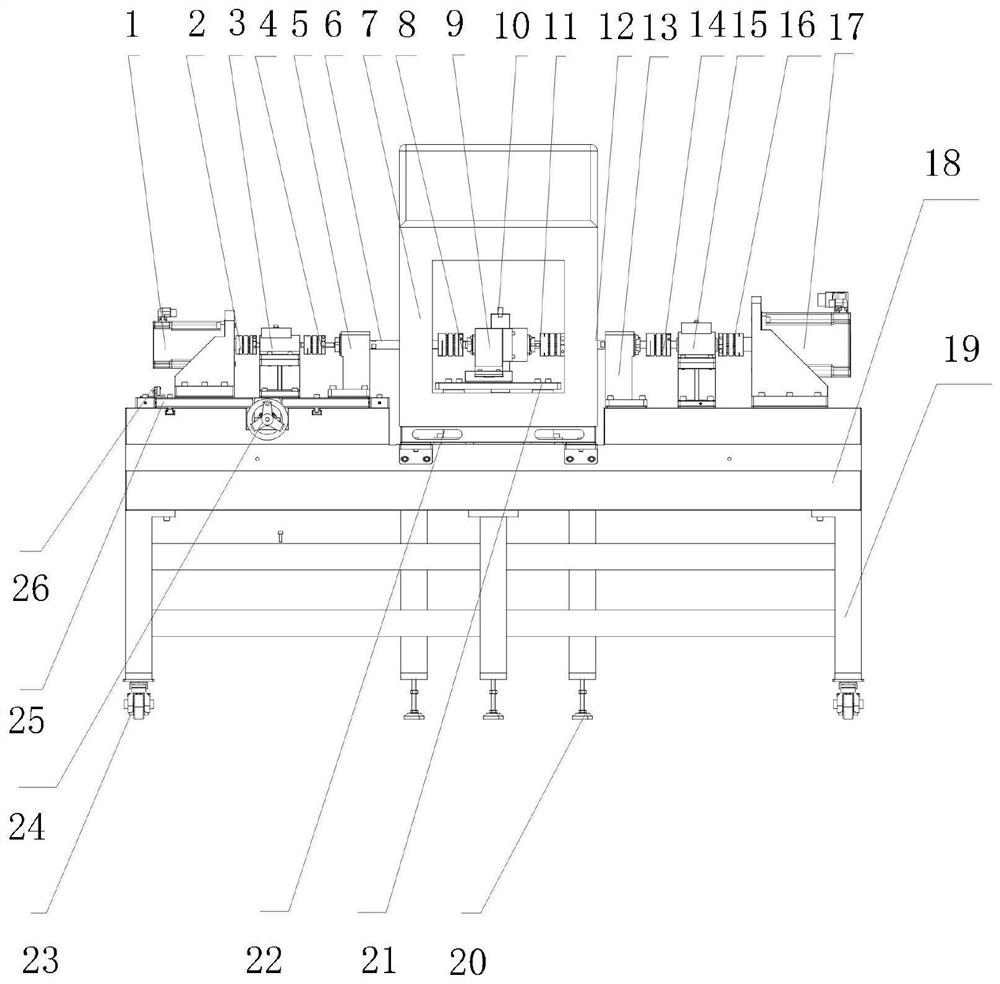

[0025] A general-purpose gear life test bench, comprising respectively a drive motor (1), a coupling (2), an input torque sensor (3), a coupling (4), an input bearing support (5), and an input spindle (6) , temperature control box (7), coupling (8), gear fixture (9), temperature sensor (10), coupling (11), output spindle (12), output bearing support (13), coupling Shaft device (14), output torque sensor (15), shaft coupling (16), load motor (17), marble platform (18), iron frame (19), ground feet (20), support plate (21), Support column (22), Fuma wheel (23), hand wheel (24), input end slide plate (25), magnetic grid (26).

[0026] As a preferred embodiment of the present invention, the driving motor (1), the input torque sensor (3), and the input bearing support (5) are uniformly placed on the input end slide plate (25), through the hand wheel (24) and the magnetic gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com