A device for preparing heterostructure anodized aluminum template

An anodized aluminum, heterostructure technology, applied in the direction of anodic oxidation, coating, surface reaction electrolytic coating, etc., can solve the problem of inability to produce double-sided heterostructure anodized aluminum template, process stability and operability Problems such as unevenness and product quality are not guaranteed, so as to achieve the effect of reducing and stabilizing the temperature of the overall reaction area, the electrolyte concentration is sufficient to meet the standard, and the process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

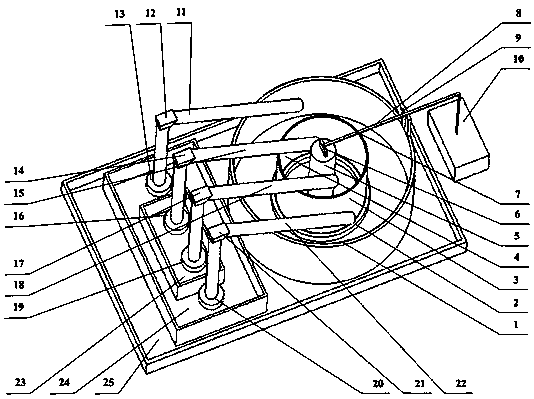

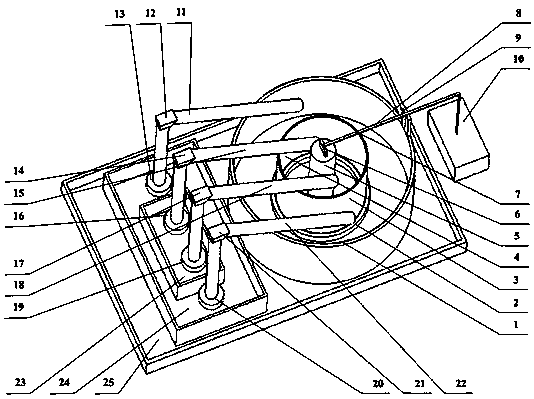

[0017] A device for preparing a heterogeneous structure anodized aluminum template described in this embodiment (such as figure 1 shown), including phosphoric acid external oxidation system, oxalic acid internal oxidation system, power supply 10, phosphoric acid circulation system, oxalic acid circulation system, cooling water circulation tank 25; external oxidation negative electrode ring 1 is a columnar structure with a closed bottom, placed in the cooling water circulation tank 25, the raw material sealing slot 2 is a ring structure, located in the middle of the bottom of the outer oxidation negative electrode ring 1, and the inner oxidation negative electrode rod 5 is fixed between the raw material sealing slots 2; the raw material (the outer oxidation surface of the raw material aluminum foil roll 3 ) and the external oxidation negative electrode circle 1 are connected to the power supply through the conductive support 8 to form a phosphoric acid external oxidation system;...

Embodiment approach

[0023] As another embodiment of the present invention, the outer oxidation negative electrode ring 1, the raw material, and the inner oxidation negative electrode rod 5 are respectively provided with a negative electrode ring electrode button 9, a raw material electrode button 7, and a negative electrode rod electrode button 6. The raw material on the raw material The electrode buckle 7 is connected to the negative pole ring electrode buckle 9 on the outer oxidation negative pole circle 1 with the power supply through the conductive support 8; .

[0024] The principle of the device described in this example is as follows: the biggest difficulty in preparing heterogeneous structure templates by double-sided oxidation is that because the common raw material aluminum foil is used as the anode, the voltage applied to the inner and outer oxidation surfaces is the same value, while different electrolytes need to be matched with different suitable materials. Voltage distribution is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com