Production method of highlight UV paint spraying product

A production method and product technology, applied in the direction of pretreatment surface, device for coating liquid on the surface, coating, etc., can solve problems such as orange peel, sink marks, surface waves of high-gloss UV products, etc., to achieve control and improvement, qualified high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

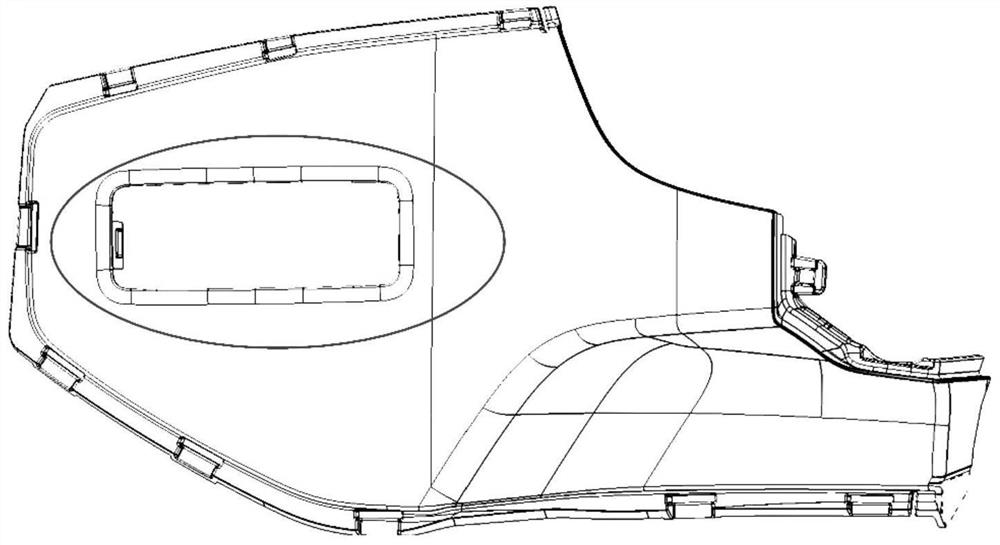

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0021] A method for producing a high-gloss UV spray paint product, the method comprising:

[0022] Mold processing method: Mold processing stage - use imported pure copper electrodes for precision EDM processing (machine model and processing parameters can be provided if necessary), after processing, use 600# oil stone for polishing, further use 800#, 1000# for polishing, and use 1200# Sandpaper, 1500# sandpaper, 2000# sandpaper for fine polishing, and finally use abrasive paste + wool ball to complete the glazing, which requires smoothness and no ripples.

[0023] Two-color injection molding with two-color injection moldi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com