Multi-angle circular stretching device for film

A stretching device and multi-angle technology, which is applied in the field of multi-angle circular film stretching, can solve the problems of central folds of the film, insufficient stretching flatness, and the stretching effect is not as perfect as imagined, and achieves a simple and compact structure. The effect of improving uniformity and flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

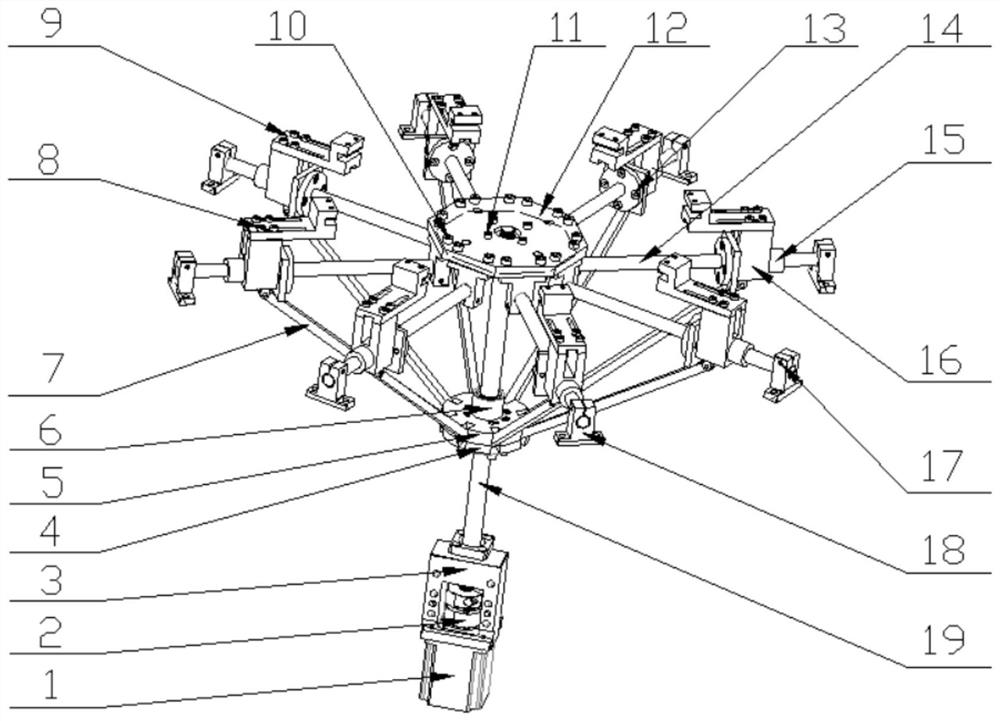

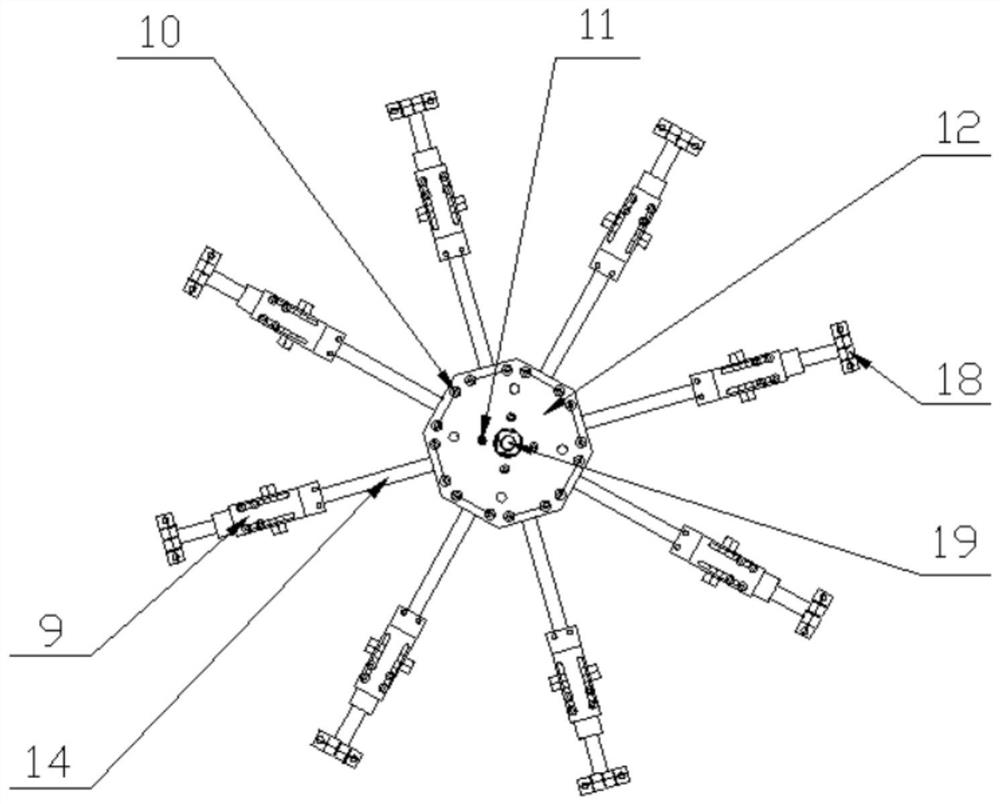

[0031] The polygonal dish in the present embodiment is octagonal.

[0032] A multi-angle film circular stretching device, such as figure 1 with figure 2 As shown, a lead screw 19 is included, the lower end of the lead screw 19 is connected to the motor shaft of the stepper motor 1 through a coupling 2, and the stepper motor 1 and the lead screw are connected through a stepper motor seat 3 to effectively control the lead screw. Axial movement of the bar. The middle part of the lead screw is provided with an up and down moving device, and the top is provided with a multi-angle plate 12 through a fixed support seat;

[0033] The above-mentioned moving device up and down comprises a connecting slider one 5 and a connecting slider two 4 which are arranged up and down and are connected by a bearing pin 5-2, such as Figure 4 As shown, the connecting slider one 5 and the connecting slider two 4 are fixed on the lead screw nut 6 by the screw one 5-1, and the lead screw nut 6 is sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com