Rice processing equipment with automatic feeding function

A rice processing and automatic feeding technology, which is applied in the directions of large containers, loading/unloading, containers, etc., can solve the problems such as the inability of the rice to be discharged smoothly, the feeding effect is poor, and the processing is interrupted, and the rice feeding effect is good. Good anti-blocking effect and anti-piling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

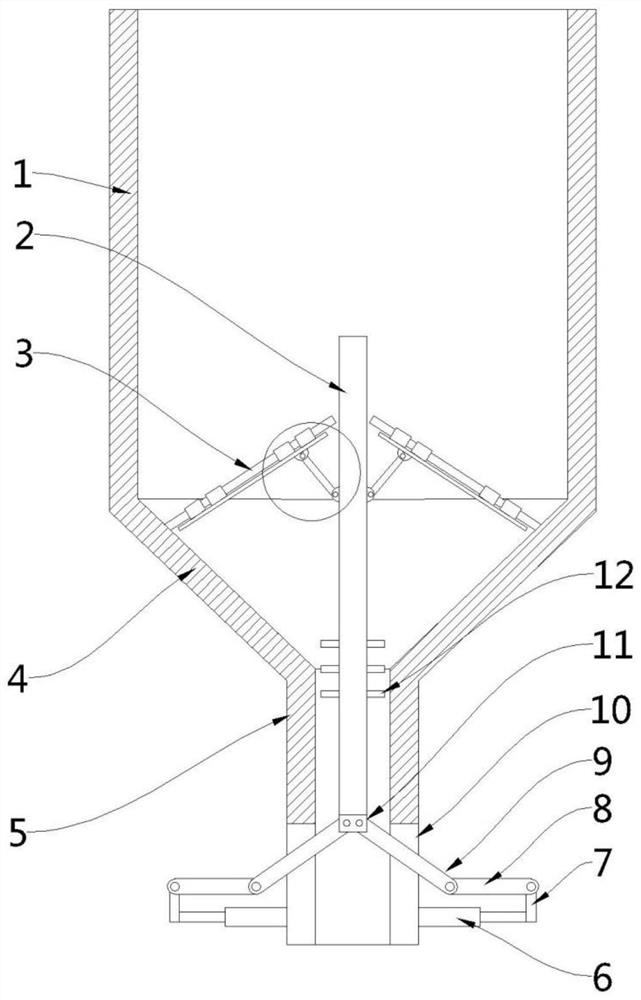

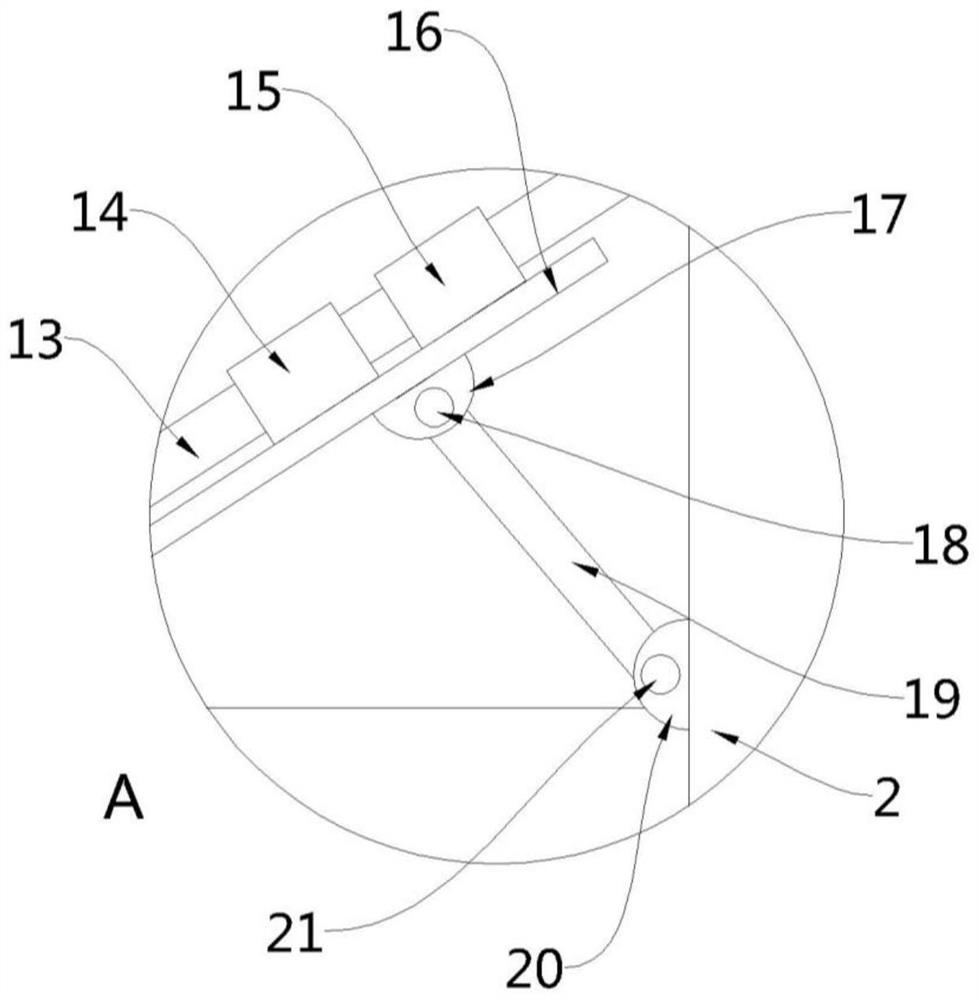

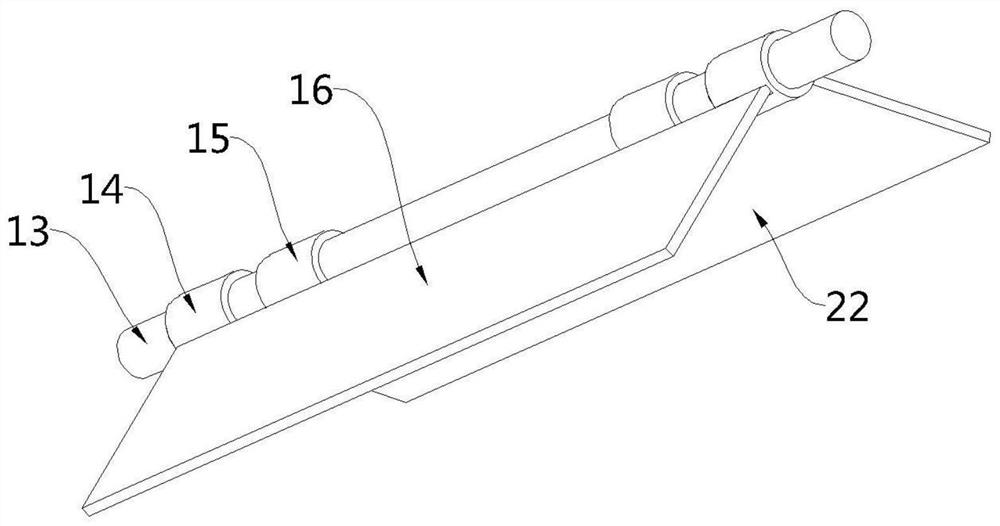

[0023] see Figure 1-3 , this embodiment provides an automatic feeding rice processing equipment, including a barrel 1, a conical material guide 4 arranged at the bottom of the barrel 1, and a lower bottom set at the bottom of the conical material guide 4 A material pipeline 5, the inside of the barrel 1 is provided with a movable rod 2 along the vertical centerline, the lower end of the movable rod 2 passes through the tapered material guide part 4 and extends to the inside of the discharge pipeline 5, the discharge The bottom of the pipeline 5 is equipped with a drive assembly for driving the movable rod 2 to move up and down, and the inside of the tapered material guide part 4 is provided with a material thinning assembly 3. Specifically, the said thinning assembly 3 includes a conical Several support shafts 13 on the inner wall of the material guide part 4 and the first sparse board 16 and the second sparse board 22 that are rotatably arranged on the support shaft 13, the ...

Embodiment 2

[0037] see figure 1 , a kind of rice processing equipment with automatic feeding. Compared with Embodiment 1, the movable rod 2 is fixedly provided with a plurality of driving rods 12 on the external wall of the rod inside the feeding pipe 5, and the driving assembly drives the movable rod 2. When moving up and down, drive the driving rod 12 to move up and down in the inner cavity of the feeding pipe 5, and then scrape the rice inside the feeding pipe 5, thereby preventing the rice from forming a blockage in the feeding pipe 5.

[0038] The embodiment of the present invention has the advantages of good rice feeding effect and good anti-blocking effect. The driving assembly drives the movable rod 2 to move up and down inside the barrel 1, the tapered material guide part 4 and the feeding pipe 5, and then passes through the first The four connecting rods 19 drive the first sparser plate 16 and the second sparser plate 22 to reciprocate and rotate along the support shaft 13, ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com