A rice processing equipment with automatic feeding

A rice processing and automatic feeding technology, which is applied to large containers, packaging, loading/unloading, etc., can solve the problems of poor feeding effect, processing interruption, and easy material blocking, etc., and achieve good anti-blocking effect and good effect Effect

Active Publication Date: 2022-05-31

南县金谷丰米业有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Most of the existing rice processing equipment includes a barrel for containing rice. The bottom of the barrel usually has a conical structure, which plays the role of guiding and controlling the material. However, due to the existence of the conical structure, the discharge diameter gradually decreases, and the rice Stacking is easy to occur in the conical structure, resulting in the failure of the rice to be smoothly discharged into the processing equipment, causing the processing to be interrupted. Therefore, the existing rice feeding mechanism has the defects of poor feeding effect and easy occurrence of material blocking. Unable to meet rice processing needs

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0031] Specifically, the power assembly 6 is a pneumatic push rod.

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

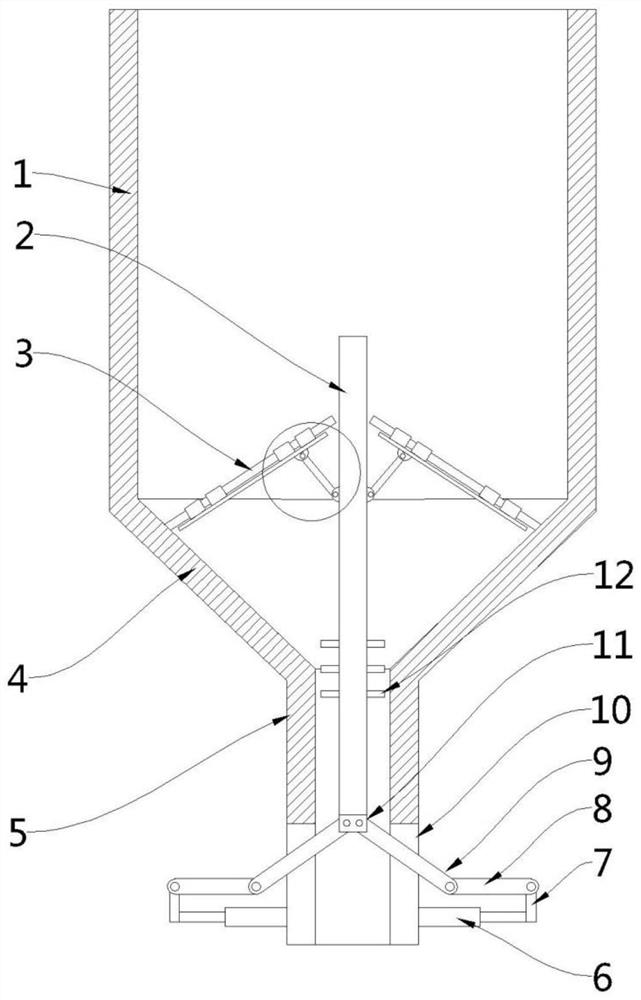

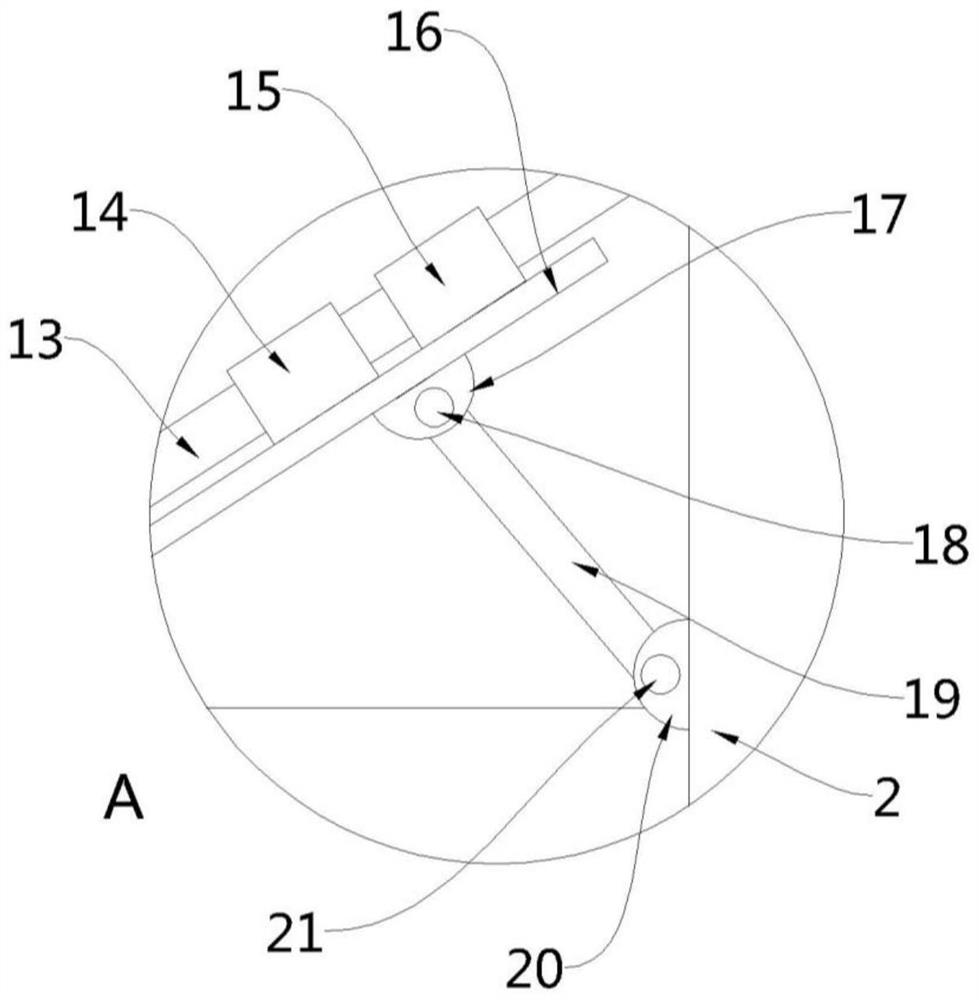

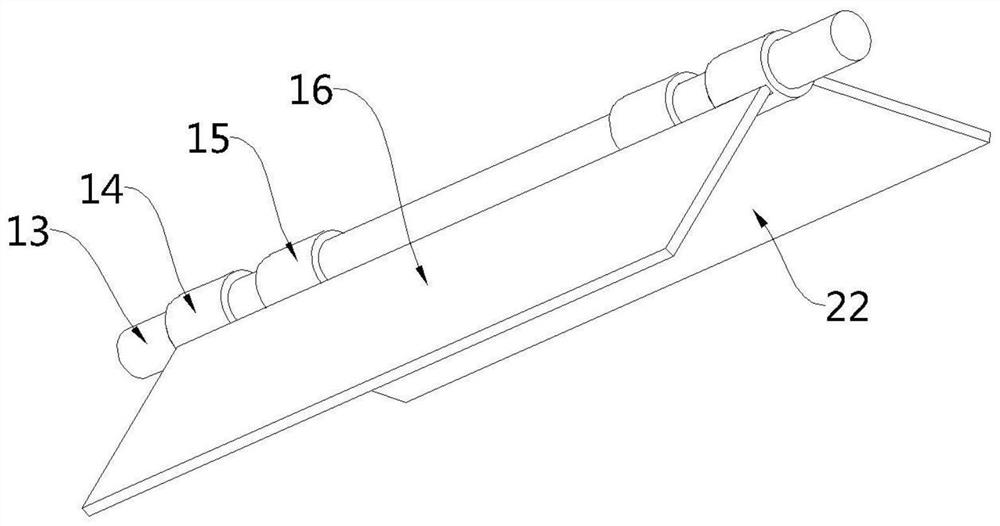

The invention provides an automatic feeding rice processing equipment, belonging to the technical field of rice processing, comprising a material cylinder, a conical material guide part arranged at the bottom of the material cylinder, and a lower material guide part arranged at the bottom of the conical material guide part The material pipe is provided with a movable rod along the vertical centerline inside the material cylinder. The embodiment of the present invention has the advantages of good rice feeding effect and good anti-blocking effect. The driving assembly drives the movable rod to move up and down in the barrel, the tapered material guide part and the inside of the feeding pipe, and then drives the movable rod through the fourth connecting rod. The first sparser plate and the second sparser plate rotate reciprocally along the support shaft, thereby using the first sparser plate and the second sparser plate to scrape the rice in the inner cavity of the conical material guide to realize the dredging of the rice and ensure that the rice can It smoothly slides into the feeding pipe from the tapered feeding part, and then is discharged from the feeding pipe into the rice processing equipment for processing, preventing the rice from forming a pile in the inner cavity of the tapered feeding part and affecting the normal feeding of rice.

Description

An automatic feeding rice processing equipment technical field The invention belongs to the technical field of rice processing, specifically a kind of rice processing equipment of automatic feeding. Background technique Existing rice processing equipment mostly includes the barrel that is used to contain rice, and the bottom of the barrel is usually a conical structure, It plays the role of guiding and controlling the material, but due to the existence of the conical structure, the discharge caliber is gradually reduced, and the rice is in the conical structure. The phenomenon of stacking is prone to occur in the interior, which causes the rice to be unable to be smoothly discharged into the processing equipment, which makes the processing interrupted. Therefore, the existing The existing rice feeding mechanism has the defects of poor feeding effect and easy material blocking, which cannot meet the needs of rice processing. SUMMARY OF THE INVENTION For the deficien...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B65D88/66B65D88/68B65G65/40

CPCB65D88/66B65D88/68B65G65/40

Inventor 王贤楷

Owner 南县金谷丰米业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com