Feeding assembly line

An assembly line and feeding hopper technology, applied in the field of assembly line, can solve the problems of small track splints and track displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

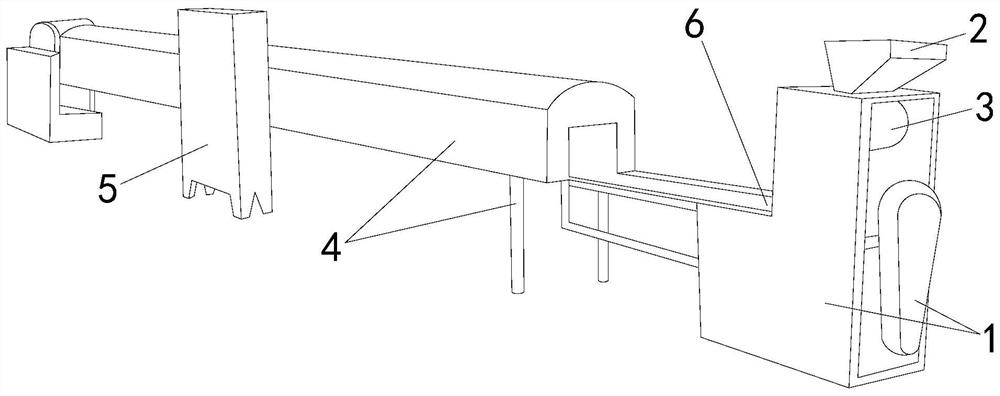

[0023] see figure 1 , the present invention provides a kind of feed assembly line, and its structure comprises: dispersion box 1, feed hopper 2, driving machine 3, conveying frame 4, controller 5, track alignment mechanism 6, described dispersion box 1 top connects feed The bucket 2 is provided with a driving machine 3 between the two to connect with it, and one end of the conveying frame 4 is connected to the dispersion box 1 and is provided with a controller 5 on its side, and the two are connected to each other. The track alignment mechanism 6 is located between the dispersion box 1 and the conveying The frame 4 is connected to the position where the two are connected. The dispersion box 1 is used as the main transmission mechanism of the assembly line equipment. The material is put into the dispersion box 1 through the feeding hopper 2 connected to the top to make it a conveying structure with a feeding function. At the same time, relying on the structure itself The drivi...

Embodiment 2

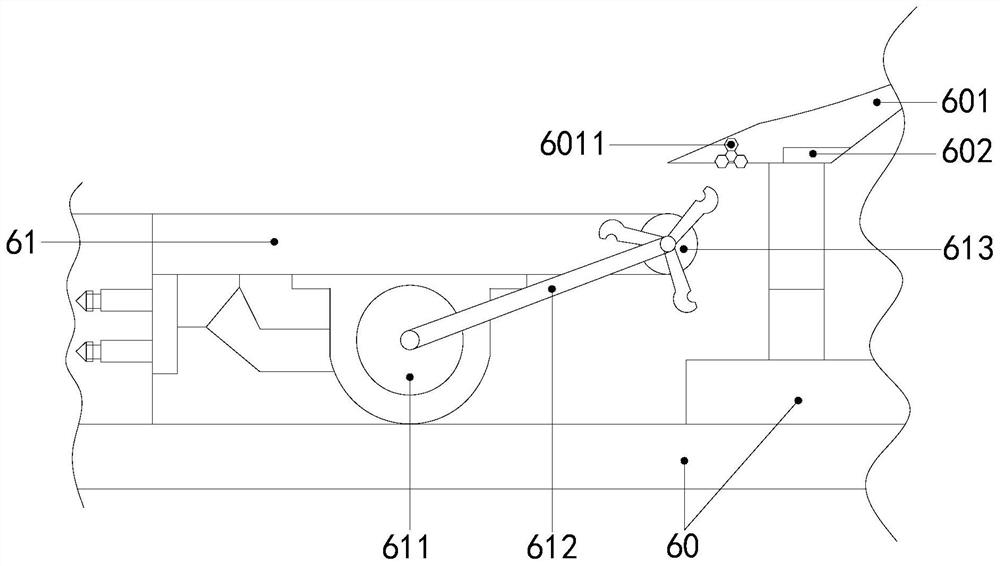

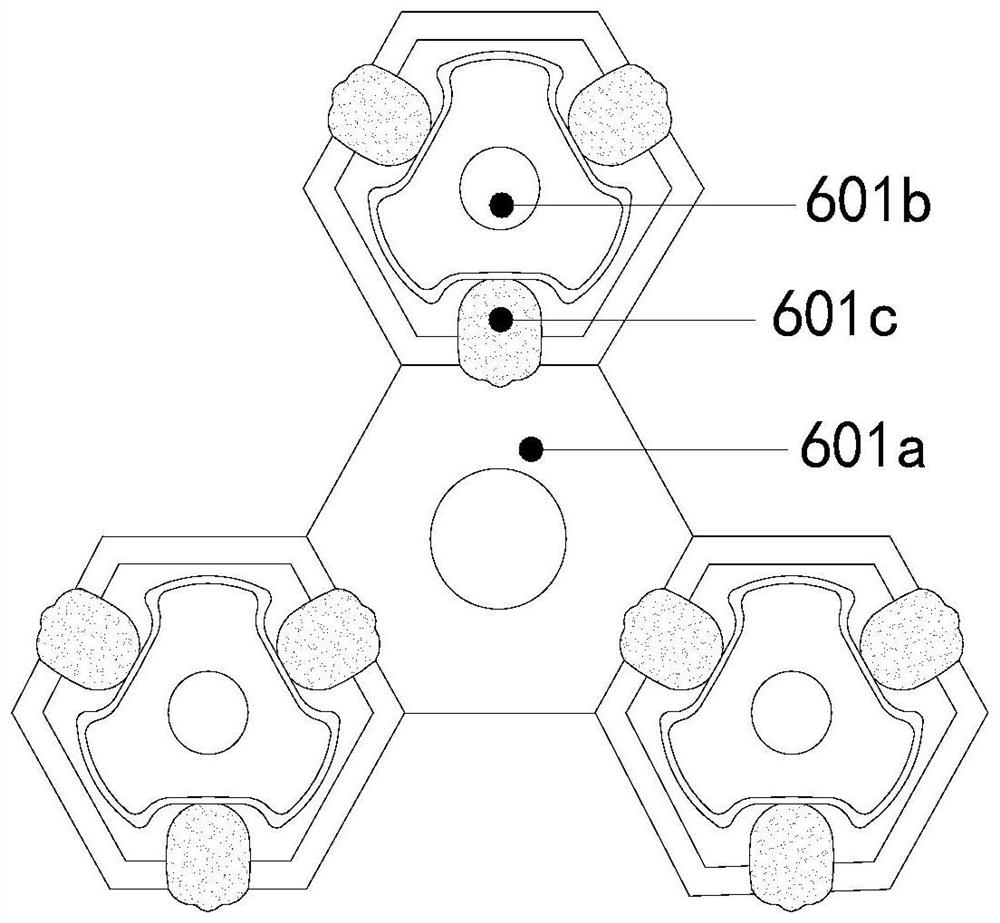

[0029] The description of the second embodiment drawn in conjunction with the first embodiment, combined with figure 2 , image 3 and Figure 5 , the blanking seat 60 and the material receiving plate 61 are set up on one side opposite to each other with a gap left between the two, and the material receiving plate 61 is respectively provided with a driving shaft 611, a transmission belt 612 and a material setting wheel 613. The side of the base point disc wheel 601a is arranged in an equilateral triangle to connect the counterweight disc 601b, and the counterweight disc 601b is equidistantly provided with weak magnetic blocks 601c to connect with it. The two are connected through each other. When the material is put into the hopper 2, the drive shaft 611 provides the source power to start the material wheel 613 through the transmission belt 612. The weak magnetic block 601c will drive the counterweight disc block 601b and The rotation of the base point disc wheel 601a produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com