Duplex block overrunning clutch

An overrunning clutch, clutch technology, applied in the direction of clutch, one-way clutch, mechanical equipment, etc., can solve the problems of damaged transmission surface, small transmission area, limited use range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

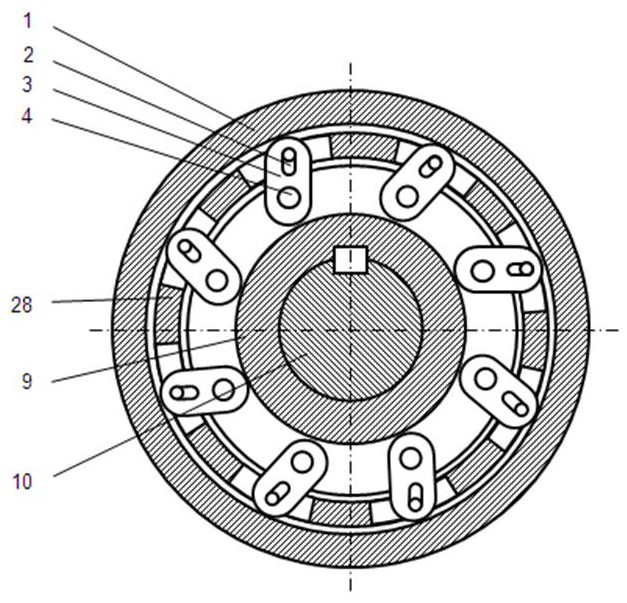

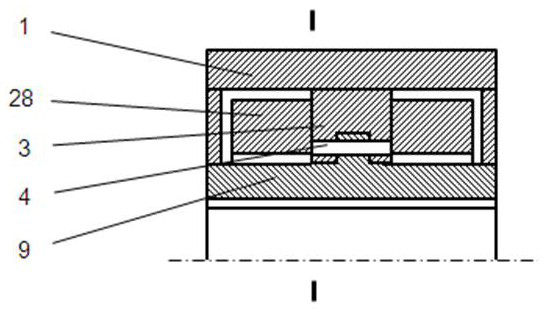

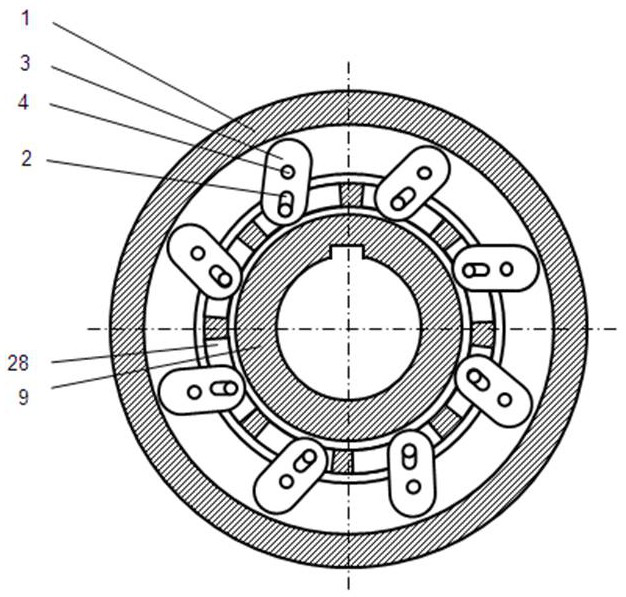

[0018] refer to figure 1 and figure 2 , the present invention has a middle ring 28, which can rotate coaxially with the outer ring 1, the clutch seat, the inner ring 9 or the central shaft 10 in the radial direction; Also one side of the middle ring 28 is rotationally connected with the outer ring 1, the clutch seat, the inner ring 9 or the central shaft 10, and the two connection points are at different radial positions, so that the middle ring 28 and the outer ring 28 linked with it through the double block 3 When an angular displacement occurs between the ring 1, the clutch seat, the inner ring 9 or the central shaft 10, it can drive the double block 3 to tilt in the circumferential direction; The change of the included angle changes in a negative correlation. When the included angle was the largest, the double joint block 3 could not contact or have no pressure contact with the outer ring 1, the clutch seat, the inner ring 9 or the central shaft 10 on the other side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com