System and method for measuring plane and line segment directions by means of cylindrical cavity liquid sections

A technology for measuring plane and cylindrical cavity, applied in the field of measurement, can solve the problems of high cost, single function, laborious measurement and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

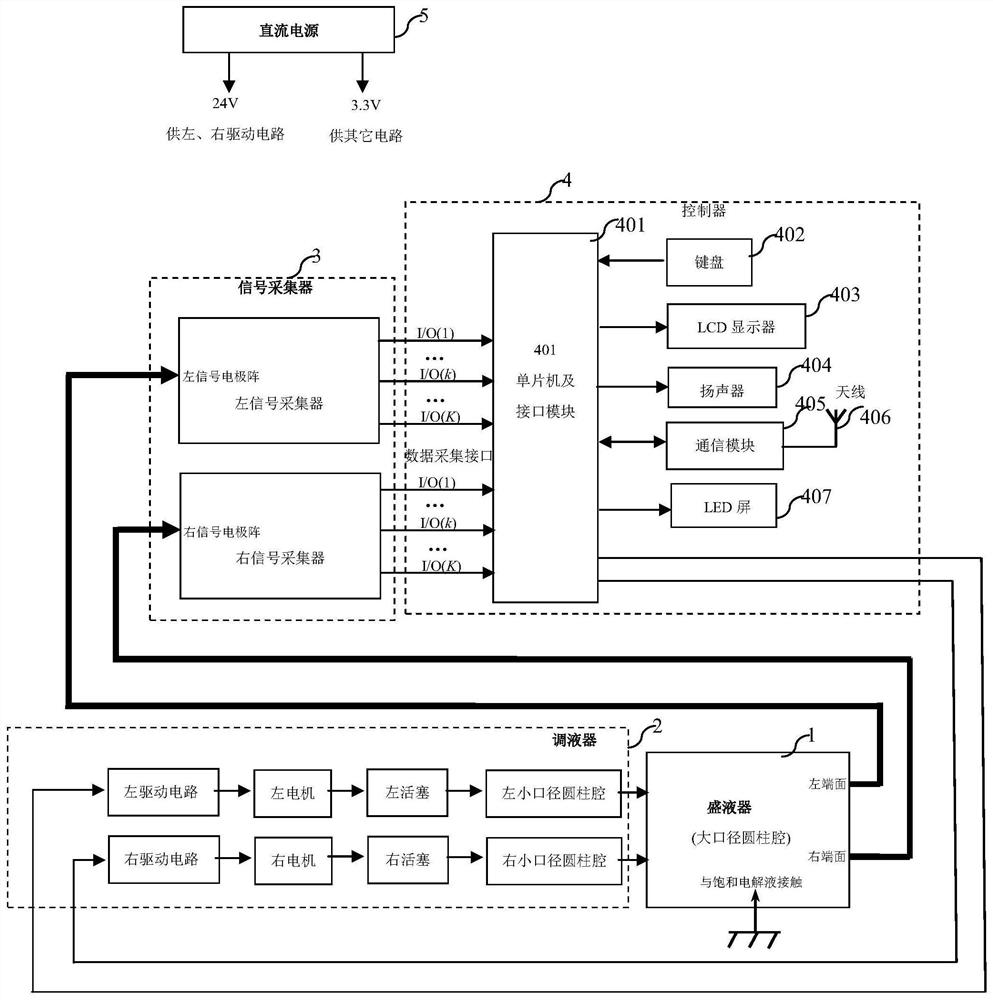

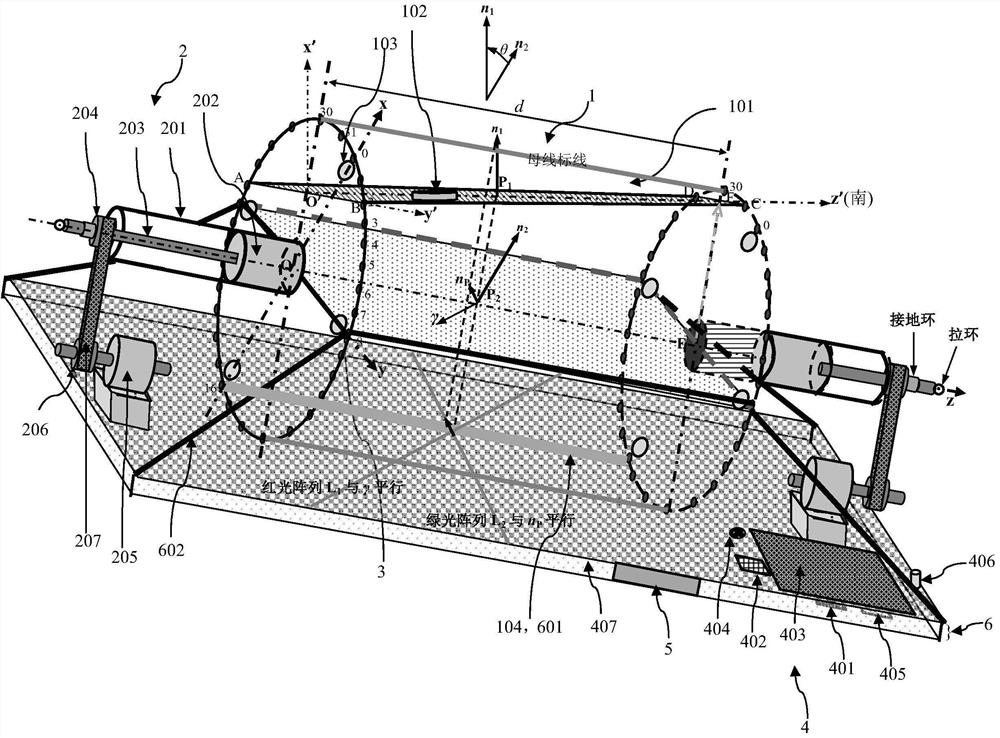

[0036] Please refer to Figure 1 to Figure 7 , the present invention is a system for measuring the direction of a plane by means of a liquid section in a cylindrical cavity, which includes a liquid container 1, a liquid regulator 2, a signal collector 3, a controller 4, a DC power supply 5, an electronic module box 6 and the attached of fasteners.

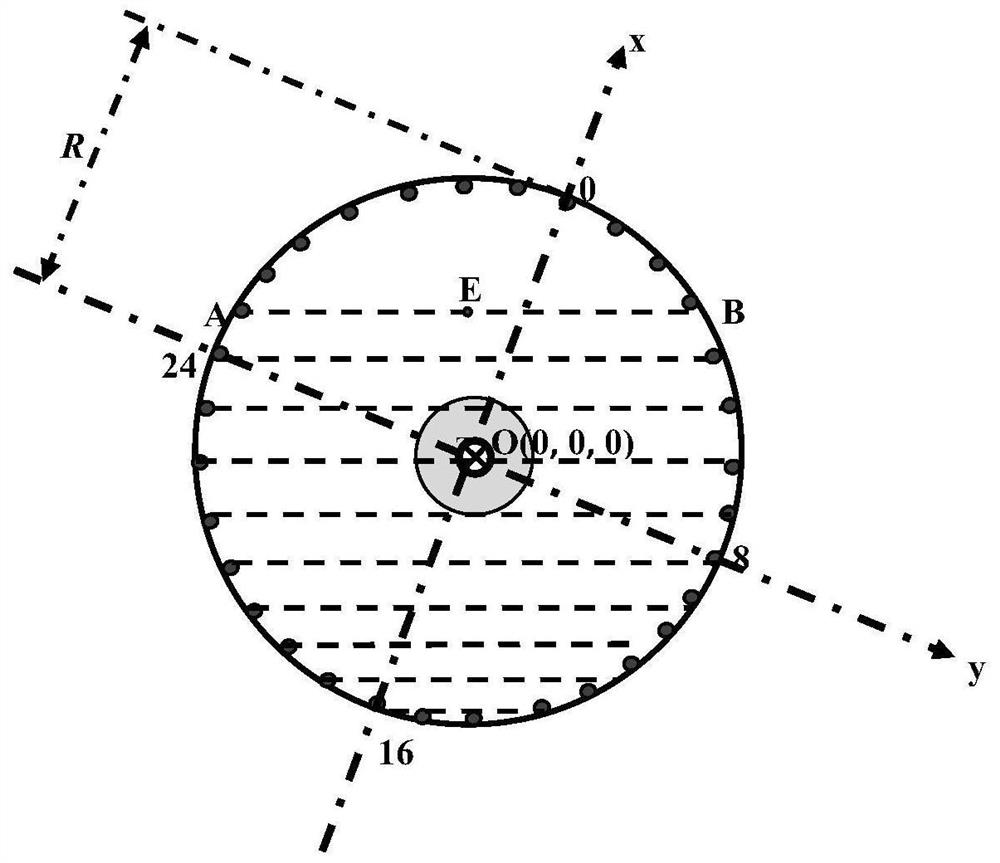

[0037] The liquid container 1, whose function is to hold the saturated electrolyte with adjustable liquid volume, includes a large-diameter cylindrical chamber 101, made of tempered glass, its side is smooth and transparent and engraved with busbar markings, and the inner side of the end face circumference is also opened Four water injection vent valves 103 are used to replenish or replace the electrolyte, and maintain the balance of internal and external air pressure when adjusting the liquid level. The large-diameter cylindrical cavity 101 is filled with saturated electrolyte, and a compass 102 with a pointer floats on the surfac...

Embodiment 2

[0129] In this embodiment, on the basis of the first embodiment, features and algorithms required for horizontal correction of the inclined plane are added. refer to Figure 9 , this embodiment also proposes a method for horizontal correction of the inclined plane, the principle is to obtain the projection component of the normal vector of the horizontal plane on the measured plane, and the orthogonal vector of the projected vector on the measured plane, to The above mentioned orthogonal vectors are rotated around the axis to correct the tilted plane to horizontal the fastest. If the user needs to correct the measured plane to be horizontal, the user is prompted to place the fulcrum of a tool such as a jack on a straight line parallel to the above-mentioned projection vector and the orthogonal vector on the measured plane, so that the correction efficiency is the highest. When it is necessary to correct the inclined plane close to the lower surface of the electronic module bo...

Embodiment 3

[0131] refer to Figure 10 to Figure 13 , this embodiment provides a system for measuring the direction of a line segment with general accuracy by means of a cylindrical chamber liquid section. The system also includes a pull ring on the basis of the system in Embodiment 1. The pull ring is divided into left and right, respectively connected to The left side of the liquid regulator and the right side of the liquid regulator away from the liquid container; Figure 10 The hanging ring is the content in the fourth embodiment, and the relevant technical features of the hanging ring and the drop are not considered in this embodiment.

[0132] This embodiment provides a method for measuring the direction of a line segment with general accuracy by means of a liquid cross section of a cylindrical cavity, using the above-mentioned system for measuring the direction of a line segment by means of a liquid cross section of a cylindrical cavity to measure the direction of a line connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com