A kind of lithium cobalt oxide composite cathode material and preparation method thereof

A composite positive electrode material and a technology of positive electrode materials, which are applied in the field of preparation of lithium cobaltate composite positive electrode materials, can solve problems such as poor cycle performance, and achieve the effects of high specific capacity, low cost, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

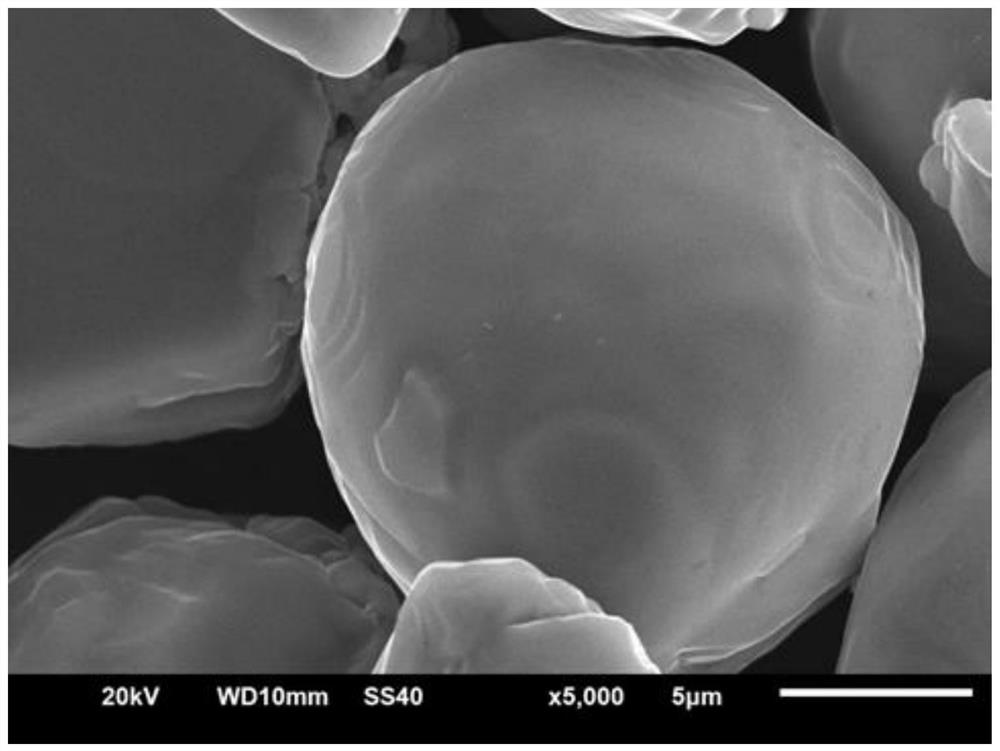

[0043] In the present invention, on the one hand, a method for preparing a high-capacity and high-voltage lithium cobalt oxide composite positive electrode material is provided, and the method includes the following steps:

[0044] Step 1, prepare the first type of positive electrode material I, and refine it;

Embodiment approach

[0045] According to a preferred embodiment of the present invention, the first type of positive electrode material I is a positive electrode material for a power lithium battery.

[0046] In a further preferred embodiment, the positive electrode material of the power lithium battery is one or more of lithium manganate, NCM523, NCM622, NCA, lithium iron phosphate, and lithium vanadium phosphate.

[0047] In a further preferred embodiment, the positive electrode material of the power lithium battery is one or more of lithium manganate, lithium iron phosphate and lithium vanadium phosphate.

[0048] Among them, the synthesis process of lithium manganate is simple, the thermal stability is good, and the rate performance and low temperature performance are superior. Lithium iron phosphate has good thermal stability and cycle performance, which is due to the stabilizing effect of the phosphate-based polyanion in the structure on the framework of the entire material. Lithium vanadiu...

Embodiment 1

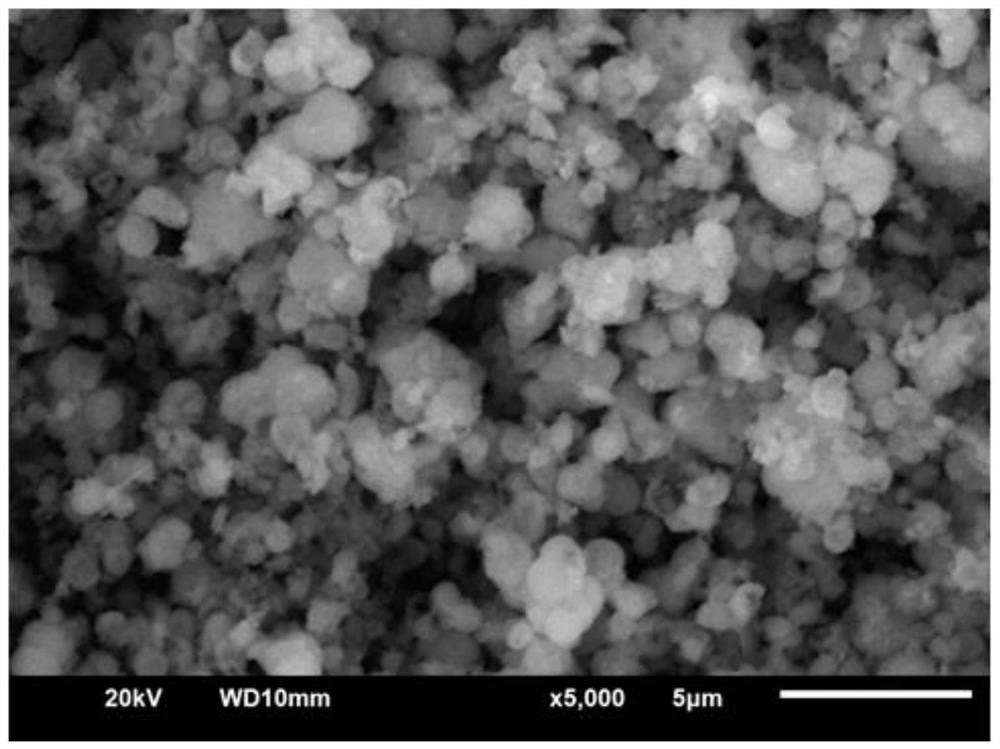

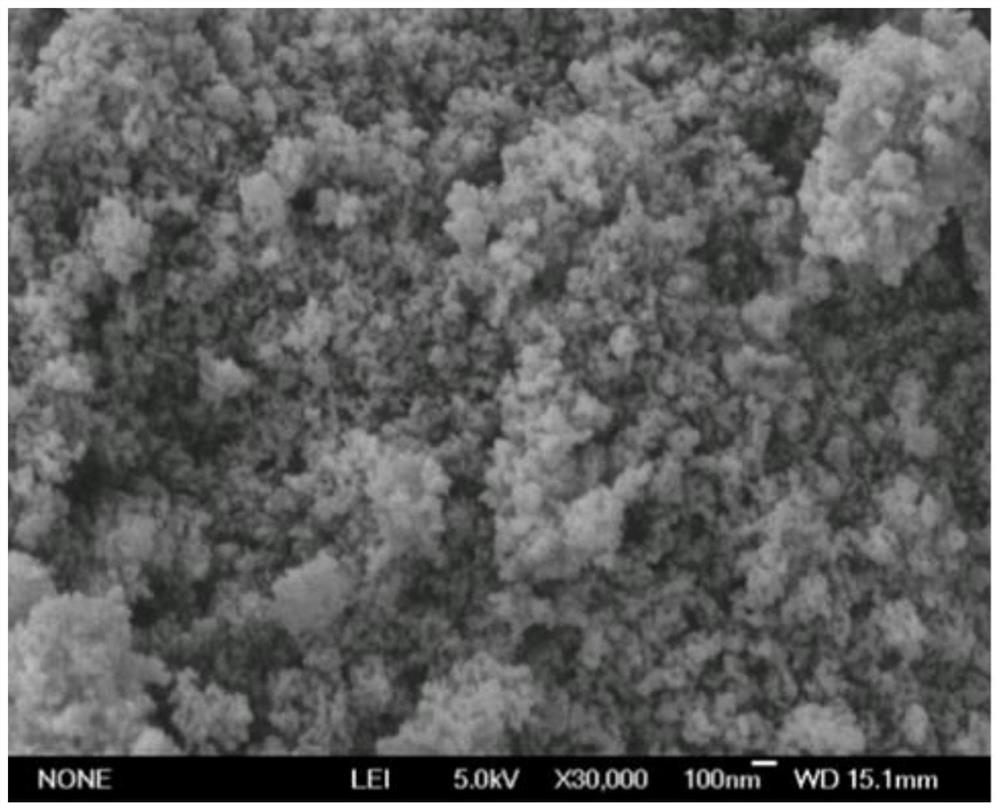

[0129] 500g of commercial lithium iron phosphate cathode material and 5000g of grinding balls were weighed and mixed uniformly according to the mass ratio of 1:10, and then added to a 5L high-speed heating mixer. Start the mixer at a speed of 100 r / min, weigh anhydrous ethanol according to a solid content of 80%, and slowly pour it into the mixer, and continue stirring for 15 minutes.

[0130] Set the cooling temperature of the high-speed heating mixer to 20°C, connect nitrogen gas to the protective gas valve, set the gas flow rate to 5L / min, adjust the speed of the mixer to 2500r / min, and continue stirring for 6 hours to complete the nanometerization .

[0131] Finally, the heating temperature of the high-speed heating mixer is adjusted to 55 degrees Celsius, the rotating speed is adjusted to 100r / min, the vacuum valve is opened, and vacuum filtration is carried out for 6 hours until the liquid in the mixed material is completely volatilized.

[0132] The mixed material is r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com