Sampling test tube cleaning equipment for clinical laboratory urine examination

A technology for cleaning equipment and laboratory, applied in the field of sampling test tube cleaning equipment for urine testing in laboratory, can solve the problems of low work efficiency, complicated operation, labor-intensive and other problems, and achieve the effect of improving work efficiency, simple operation and saving labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

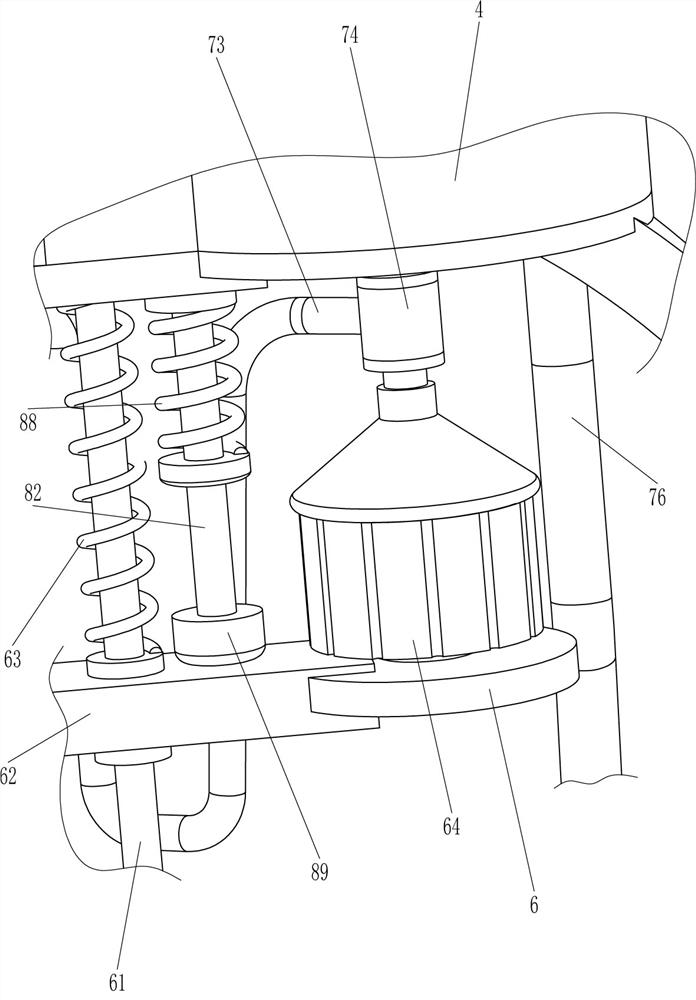

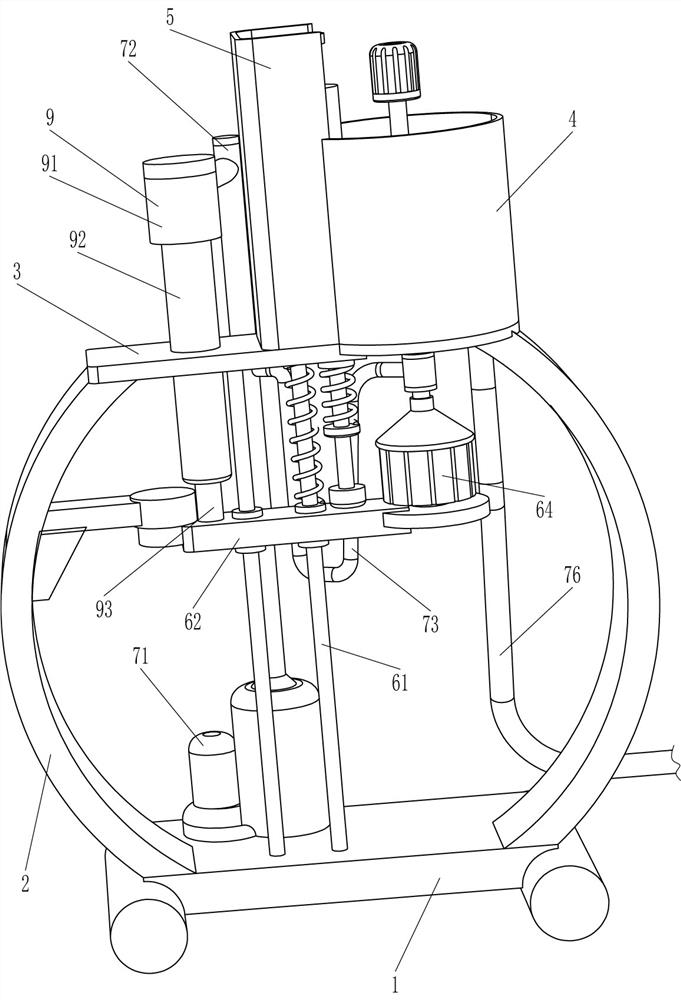

[0026] A kind of sampling test tube cleaning equipment for laboratory urine test, such as Figure 1-4 As shown, it includes a support 1, an arc plate 2, a mounting plate 3, a water collection frame 4 and a water retaining groove 5. The left and right sides of the top of the support 1 are connected with the arc plate 2, and the top of the arc plate 2 on both sides A mounting plate 3 is connected between them, a water collection frame 4 is connected to the top right side of the mounting plate 3, a water retaining groove 5 is connected between the left side of the water collection frame 4 and the mounting plate 3, and a cleaning mechanism 6 and a water injection mechanism 7 are also included. A cleaning mechanism 6 is provided between the seat 1 and the mounting plate 3 , and a water injection mechanism 7 is provided between the support 1 and the cleaning mechanism 6 .

[0027] The cleaning mechanism 6 includes a slide bar 61, a slide plate 62, a first spring 63, a driving motor ...

Embodiment 2

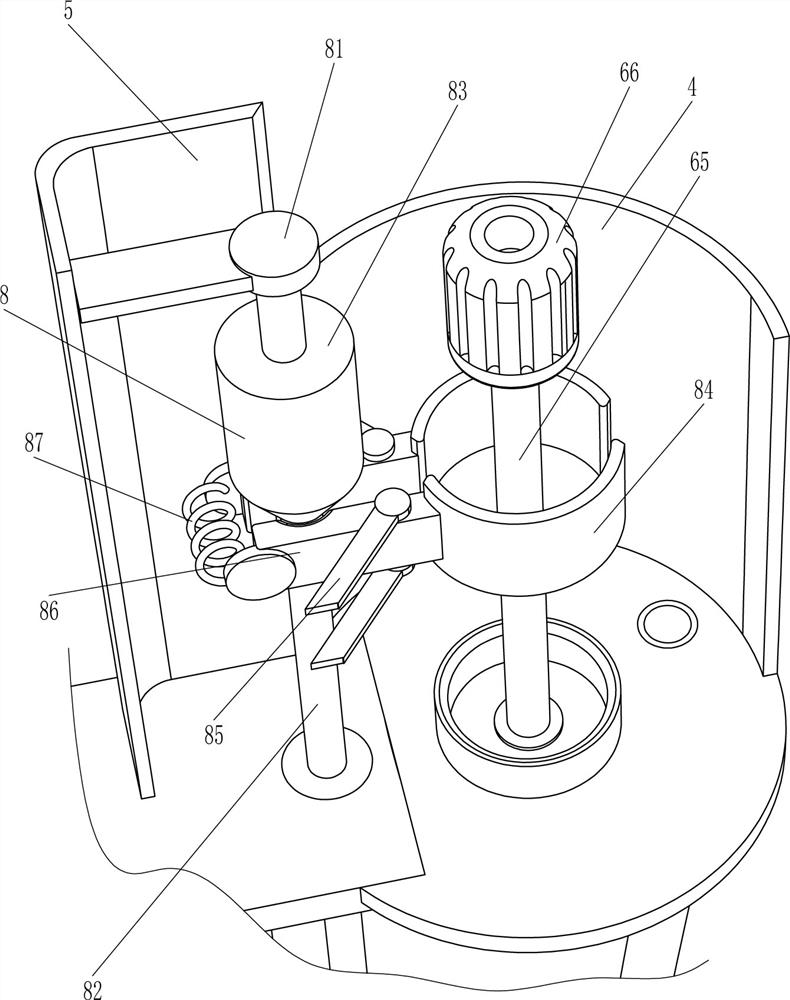

[0031] On the basis of Example 1, such as figure 2 and Figure 4 As shown, a clamping mechanism 8 is also included, and the clamping mechanism 8 includes a baffle plate 81, a sliding rod 82, a tapered column 83, a clamp ring 84, a hinged rod 85, an arc contact plate 86, a second spring 87, a second Three springs 88 and a contact block 89, the upper part of the water retaining tank 5 is connected with a baffle 81, the right side of the mounting plate 3 is slidably connected with a sliding rod 82, the baffle 81 is used to limit the sliding rod 82, and the upper part of the sliding rod 82 is connected There is a tapered column 83, and the front and rear walls of the water retaining tank 5 are connected with hinged rods 85, the hinged rods 85 are hingedly connected with arc contact plates 86, and the arc contact plates 86 are connected with clamp rings 84, and the two arc contacts The second spring 87 is connected between the plates 86, the tapered column 83 cooperates with the ...

Embodiment 3

[0034] On the basis of Example 2, such as figure 1 As shown, a push mechanism 9 is also included. The push mechanism 9 includes a water sleeve 91, a piston pipe 92 and a push rod 93. The top of the vertical pipe 72 is connected with a water sleeve 91, and the water sleeve 91 communicates with the vertical pipe 72. The water jacket 91 is connected with a piston tube 92 , the piston tube 92 passes through the mounting plate 3 , and a push rod 93 is slidably connected in the piston tube 92 , and the bottom of the push rod 93 is connected with the slide plate 62 .

[0035]The water ejected in the standpipe 72 is also injected into the piston tube 92 through the water receiving sleeve 91, more and more water in the piston tube 92 can push the push rod 93 to move downward, and the push rod 93 moves downward to push the slide plate 62 downward. Move, like this, just do not need manually to push slide plate 62 to move downwards, effectively saved manpower.

[0036] like Figure 5 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com