Movable integrated-type filter automatic assembling machine and system used for nuclear power plant

A filter and integrated technology, which is applied in the field of mobile integrated filter intelligent assembly machine and system for nuclear power plants, can solve the problems of unsuitable integrated filter assembly, low assembly efficiency, poor precision, etc., and achieve automatic operation , Accurate and fast assembly, low adjustment difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

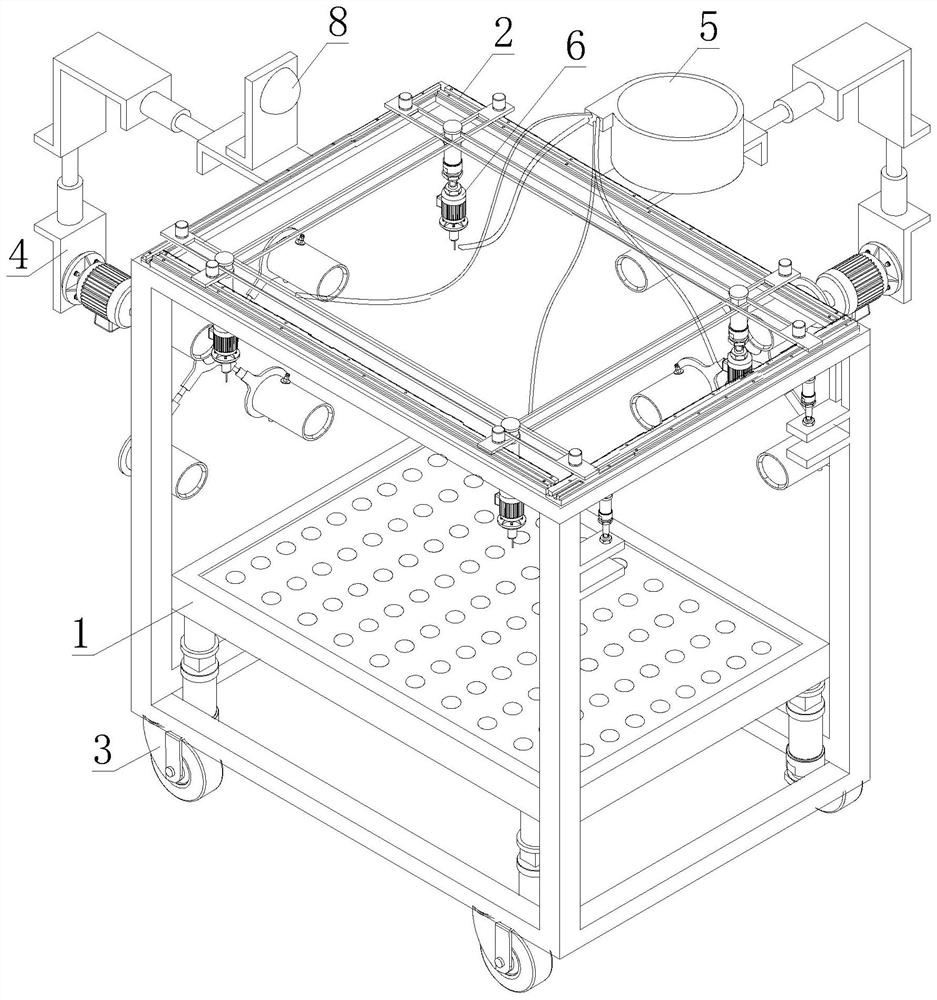

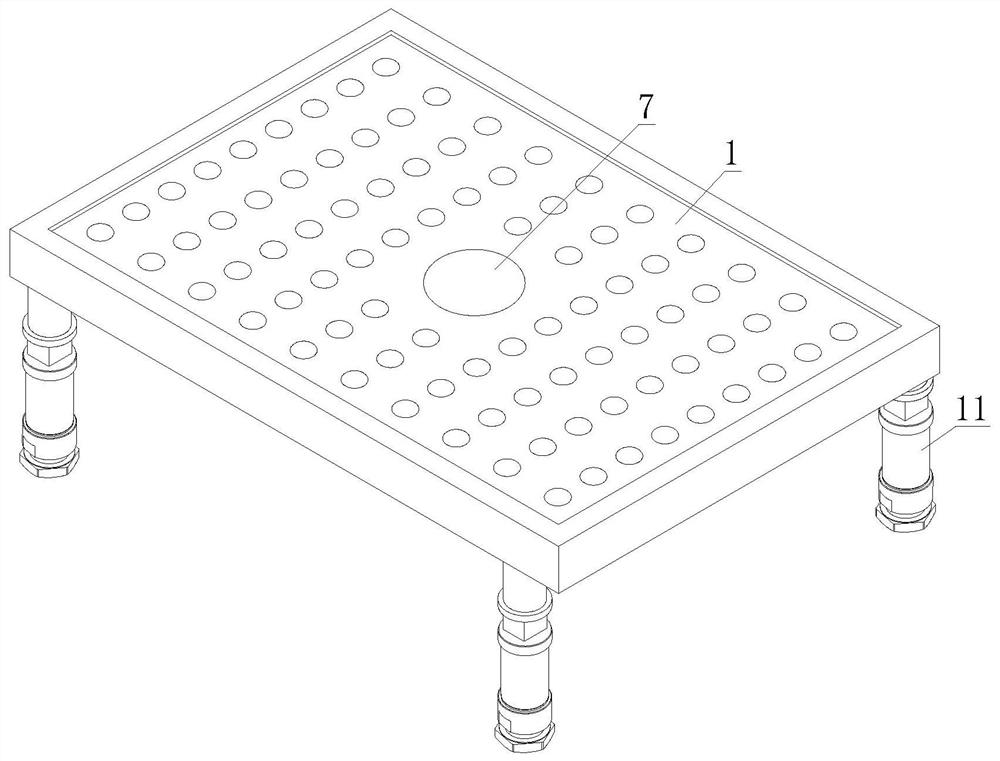

[0035] refer to Figure 1 to Figure 2 , a mobile integrated filter intelligent assembly machine for nuclear power plants, including a vacuum platform 1, a bracket 2, a running mechanism 3, a turning device 4, a screw feeding device 5 and a screwing device 6, and the lower end of the bracket 2 is provided with a vacuum platform 1. The four corners of the lower end of the vacuum platform 1 are equipped with lifting cylinders 11, the upper surface of the vacuum platform 1 is equipped with a gravity sensor 7, the gravity sensor 7 is connected to the scanner 8 through wireless signals, and the lower bottom surface of the bracket 2 is installed. The traveling mechanism 3 is equipped with a screwing device 6 on the upper end of the support 2, and the screwing device 6 is connected with the screw feeding device 5, and the turning device 4 is installed on the support 2.

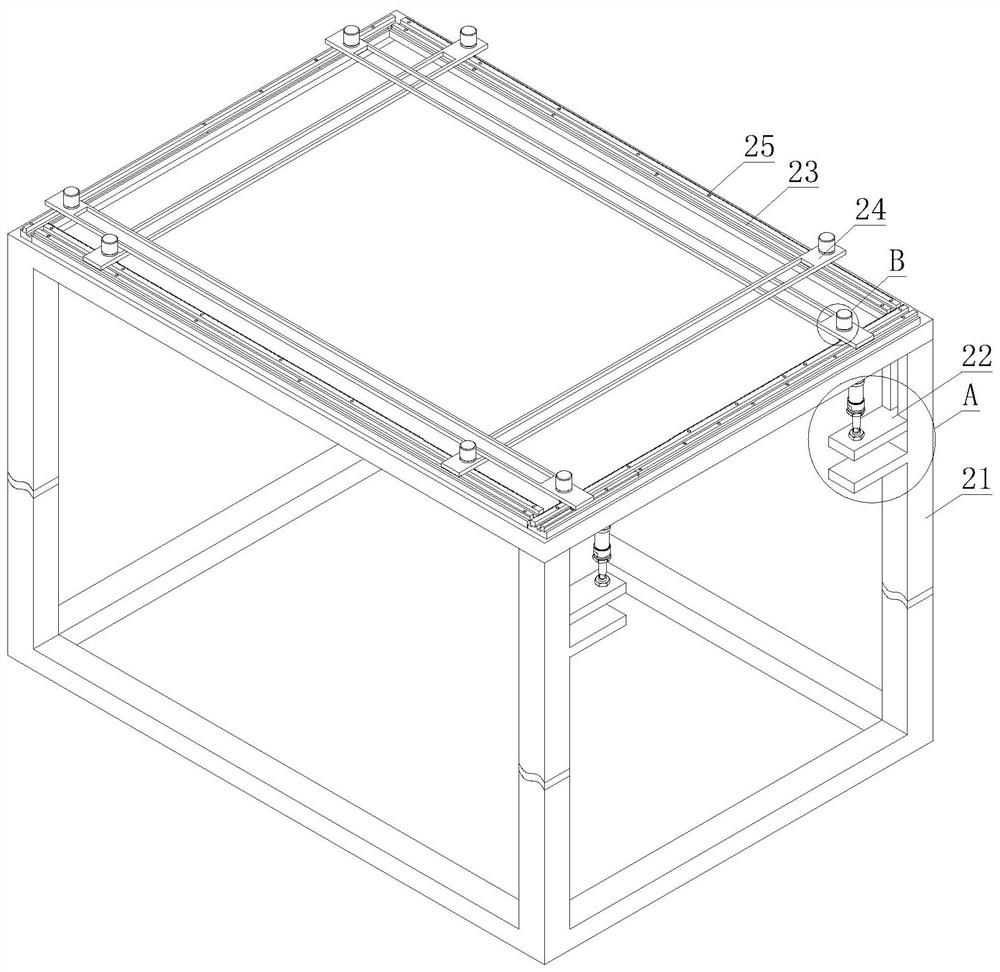

[0036] refer to Figure 3 to Figure 5, the support 2 includes a frame body 21, a filter screen inlet assembly 22, ...

Embodiment 2

[0042] refer to Figure 10 , a mobile integrated filter intelligent assembly machine for nuclear power plants, including a vacuum platform 1, a bracket 2, a running mechanism 3, a turning device 4, a screw feeding device 5 and a screwing device 6, and the lower end of the bracket 2 is provided with a vacuum platform 1. The four corners of the lower end of the vacuum platform 1 are equipped with lifting cylinders 11, the upper surface of the vacuum platform 1 is equipped with a gravity sensor 7, the gravity sensor 7 is connected to the scanner 8 through wireless signals, and the bottom surface of the bracket 2 is installed. The traveling mechanism 3, the upper end of the support 2 is equipped with a screwing device 6, the screwing device 6 is connected with the screw feeding device 5, and the support 2 is equipped with a turning device 4;

[0043] The support 2 includes a frame body 21, a filter screen inlet assembly 22, a slide rail 23, a beam assembly 24 and a rack 25, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com