Concrete stirring device convenient to feed

A mixing device and concrete technology, which is applied in the direction of cement mixing device, clay preparation device, sales raw material supply device, etc., can solve the problems of low efficiency, time-consuming and laborious, etc., and achieve high mixing efficiency, good mixing effect and high feeding efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

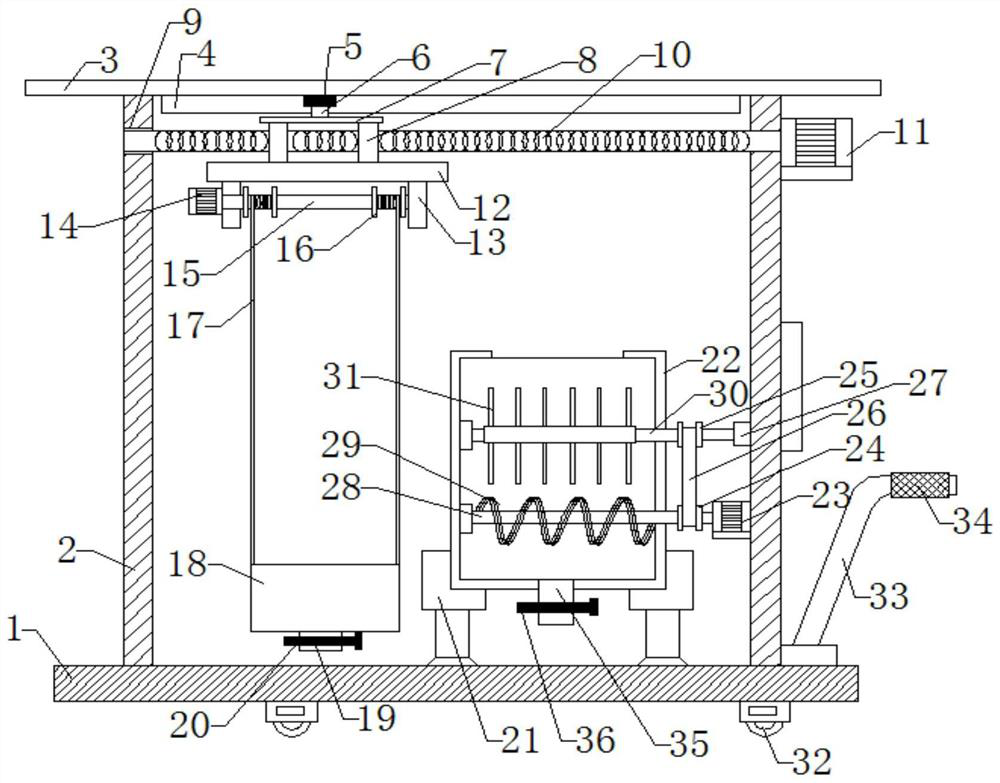

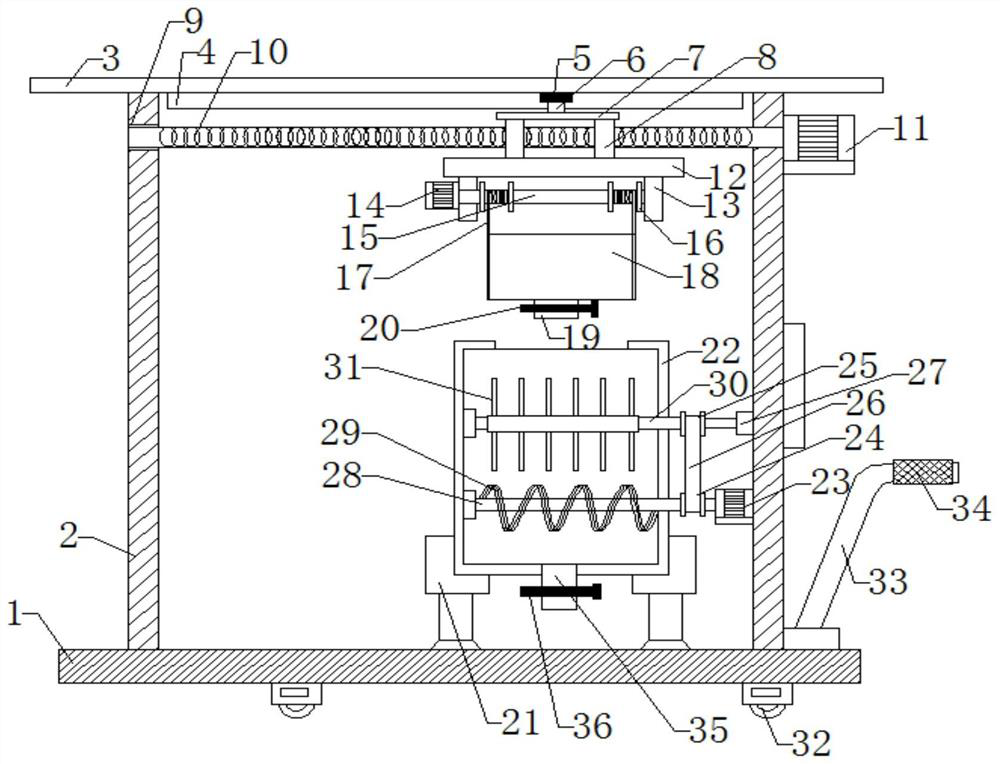

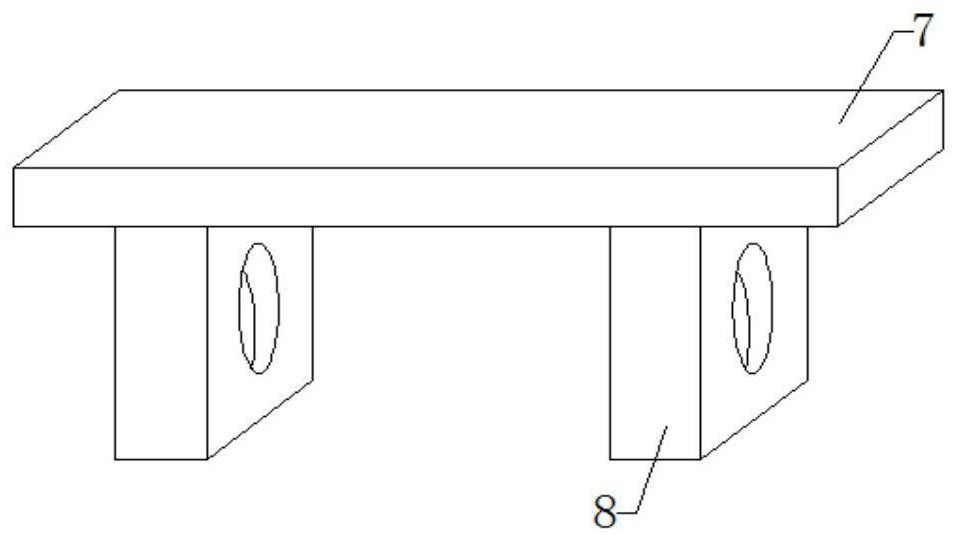

[0021] see Figure 1~3 , in an embodiment of the present invention, a concrete mixing device convenient for feeding includes a base 1, side plates 2 are fixedly installed on the left and right sides of the upper surface of the base 1, and the upper sides of the two side plates 2 are fixedly installed with the same A beam 3; the upper end of the side plate 2 on the right side is fixedly installed with a first motor 11, and the output end of the first motor 11 is fixedly connected with a threaded rod 10; the side plate 2 on the left side A bearing 9 is fixedly installed in the upper end plate wall, and one end of the threaded rod 10 away from the first motor 11 passes through the side plate 2 on the right side and extends to the side plate 2 on the left side and is fixedly installed in the bearing 9; The threaded rod 10 is provided with two moving seats 8 matched with the threaded rod 10, the same connecting plate 7 is fixedly installed on the upper side of the two moving seats ...

Embodiment 2

[0028] see Figure 1~2 , in order to make the mixing effect of the convenient concrete mixing device of the present invention better, this embodiment has been further improved on the basis of embodiment 1, and the improvement is: the inner side of the side plate 2 located on the right side A fixed seat 27 is fixedly installed, and the fixed seat 27 is located above the third motor 23; a driven rotating shaft 30 is rotatably installed in the fixed seat 27, and the driven rotating shaft 30 passes through the right side of the mixing box 22. The wall extends to the inside of the stirring box 22, and the driven rotating shaft 30 is fixedly installed with a stirring blade 31 on the shaft wall inside the stirring box 22; There is a driving wheel 24 , and a driven wheel 25 is fixedly sleeved on the shaft wall at one end of the driven rotating shaft 30 close to the fixed seat 27 , and a belt 26 is arranged between the driven wheel 25 and the driving wheel 24 .

[0029] The working pr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap