Waste plastic housing crushing device for home appliance production and crushing method

A waste plastic and crushing device technology, which is applied in the direction of plastic recycling, recycling technology, mechanical material recycling, etc., can solve the problems of affecting the crushing efficiency and incomplete crushing, so as to improve efficiency, facilitate crushing operation, and facilitate waste reuse Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

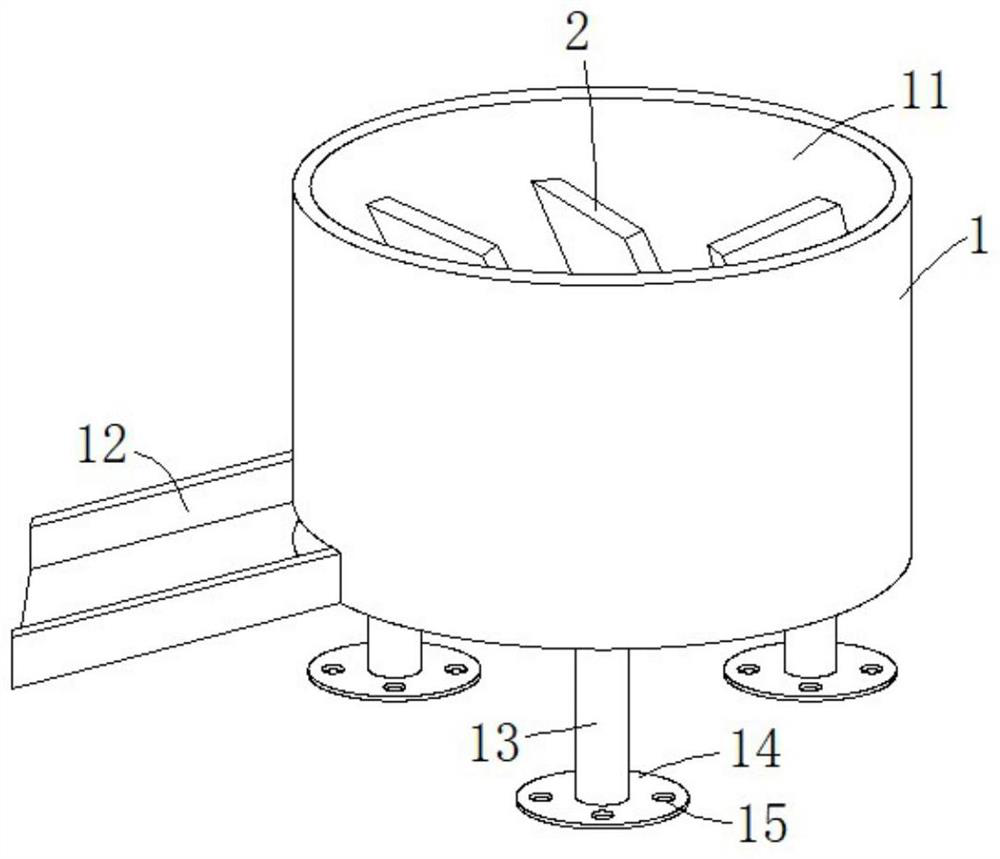

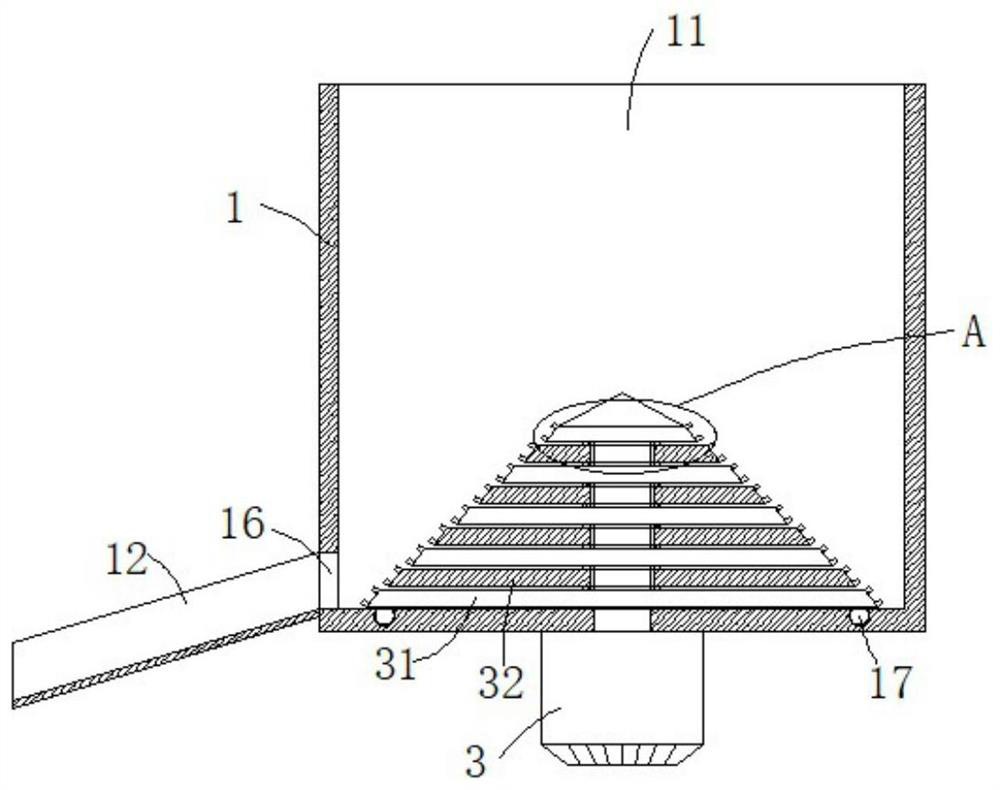

[0028] see Figure 1-3 , this embodiment provides a crushing device for waste plastic shells used in home appliance production. There is a crushing motor 3, and the crushing motor 3 is connected with a first crushing disc 31 through a power shaft. A plurality of steel balls 17 are embedded in the edge of the bottom end surface of the crushing cavity 11 of 1, which are evenly distributed in a ring shape and are rotated and attached to the bottom end surface of the bottommost first crushing disc 31 .

[0029] The edge position of the bottom end surface of the crushing cylinder 1 is vertically welded with several evenly spaced support legs 13, the bottom end surface of each support leg 13 is provided with a mounting plate 14, and the edge position of each mounting plate 14 is provided with several evenly spaced The mounting holes 15.

[0030] The radial side wall of the crushing cavity 11 of the crushing cylinder 1 is provided with several annular baffles 2 evenly spaced apart,...

Embodiment 2

[0038] see Figure 1-3 , further improvements have been made on the basis of Example 1:

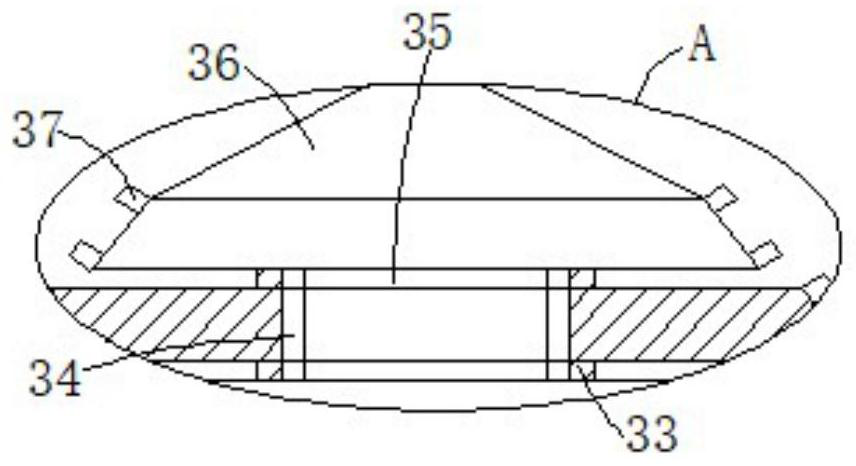

[0039]The top surface of the uppermost first crushing disc 31 is provided with a conical top block 36. By setting the conical top block 36, it is avoided that waste plastic shells of household appliances remain on the top surface of the topmost first crushing disc 31;

[0040] The front section of each first crushing disk 31 and each second crushing disk 32 is a truncated cone structure, and the radius of each first crushing disk 31 and each second crushing disk 32 decreases proportionally from bottom to top , so that it is convenient to slide down along the radial outer wall of each first crushing disc 31 and each second crushing disc 32, which is convenient for rapid crushing operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com