Integrated kitchen waste crushing, screening and air selection equipment

A food waste and screening technology, which is applied in the fields of screening, winnowing integrated equipment, and food waste crushing, can solve the problems of large power consumption, high energy consumption of the production line, and complicated structural design, so as to shorten the length and promote the flow , The effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, preferred embodiment of the present invention is described:

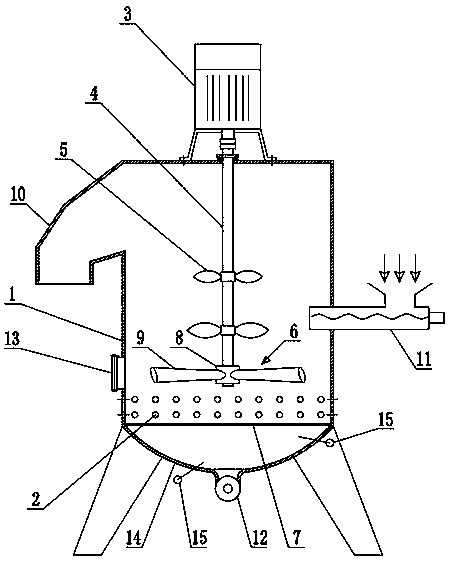

[0025] Such as Figures 1 to 5 As shown, an integrated equipment for crushing, screening, and winnowing of food waste includes: a tank body 1 , an integrated device for introducing wind and crushing, and a screening screen 7 .

[0026] in:

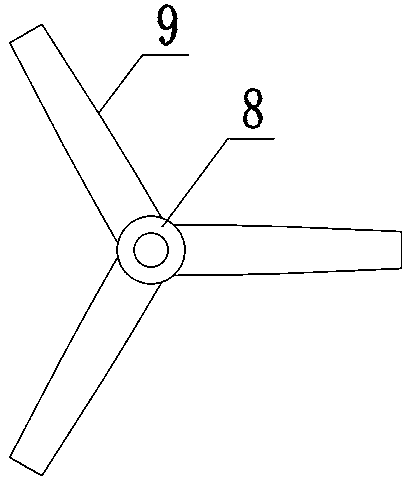

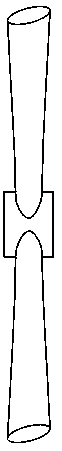

[0027] The tank body 1 is cylindrical as a whole and vertically arranged, and a plurality of air inlet holes 2 are arranged on the outer wall of the tank body 1; Arrangement, the air inlet hole 2 is located between the crushing rod 6 and the screening screen 7; a light material outlet 10 is provided near the top position on the outer circumference of the tank body 1, and a feeding screw is provided at the upper middle position on the outer circumference of the tank body 1 The conveyor 11 is provided with a discharge screw conveyor 12 at the lower end of the tank body 1, and the upper side of the tank body 1 is located on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com