Outlet conveying belt assembly of belt bonding machine

A technology for conveyor belts and tape stickers is applied in the field of export conveyor belt components, which can solve the problems of increased pollution, troublesome handling and high cost of plastic pull rings, and achieve the effects of reducing friction, compact equipment structure, and improving smoothness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

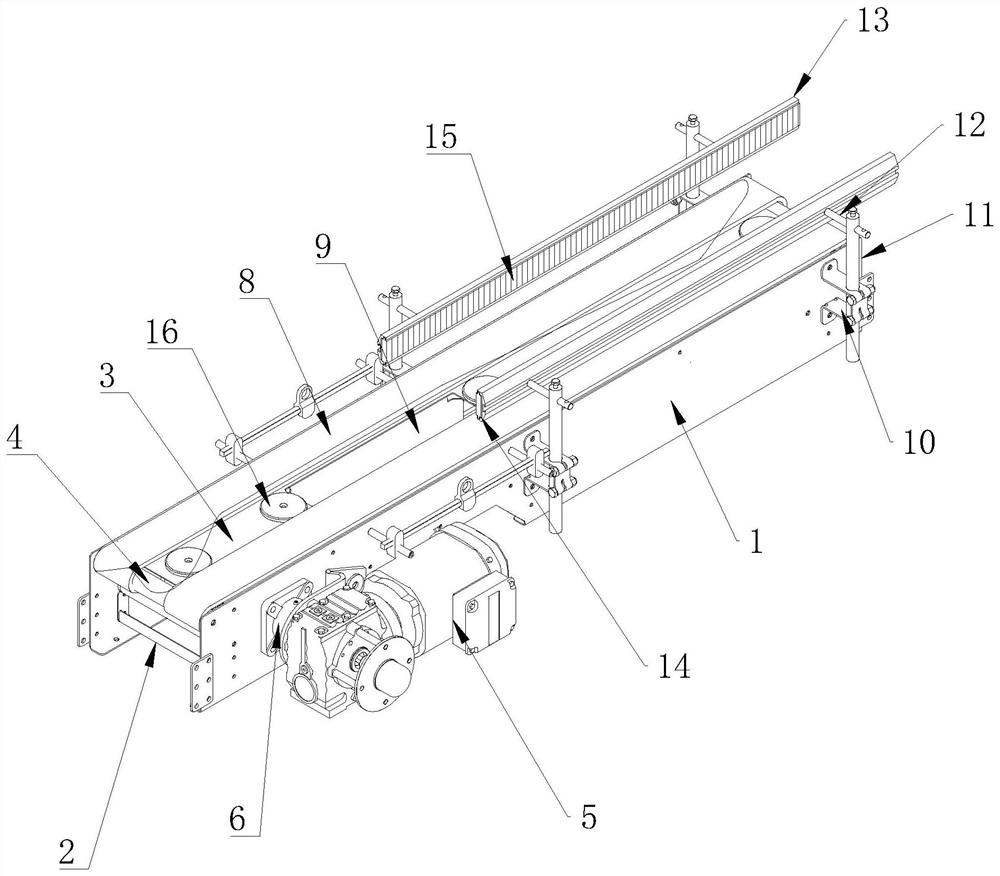

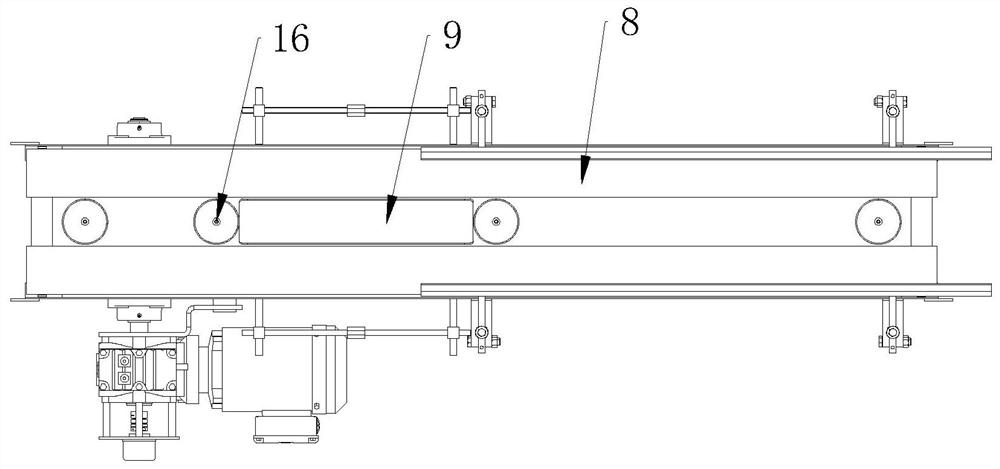

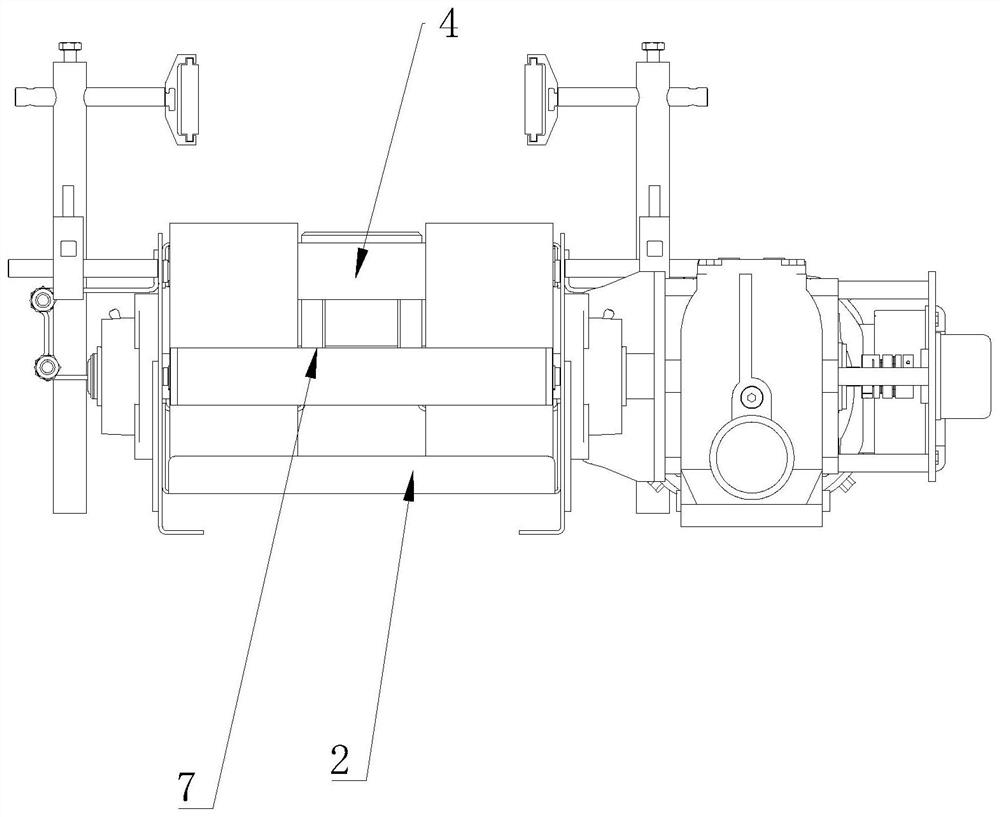

[0015] Such as figure 1 As shown, an outlet conveyor belt assembly of a tape sticking machine includes two side plates 1, the two side plates 1 are fixedly connected by connecting the fixing plate 2, and a bottom supporting plate is also arranged between the two side plates 1 3. The driven rollers 4 arranged at both ends of the bottom support plate 3 and the power assembly arranged under the bottom support plate 3, the power assembly includes a motor 5 arranged on the side plate 1, and a motor 5 arranged between the two side plates 1 The driving shaft of the drive shaft and the bearing housing 6 arranged on the two side plates 1, several mesh pulleys 7 are arranged on the intermediate shaft, two driven rollers 4 and mesh pulleys 7 are provided with two Mesh belt 8, said bottom support plate 3 is provided with the through groove 9 that stretches out for tape sticking mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com