Continuous vertical automatic conveying device

A conveying device and automatic technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of discontinuous conveying, labor-intensive, work efficiency and work safety are easily affected by human factors, etc., to improve work efficiency. Efficiency and work safety, reduce labor cost and labor intensity, and improve the effect of goods delivery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

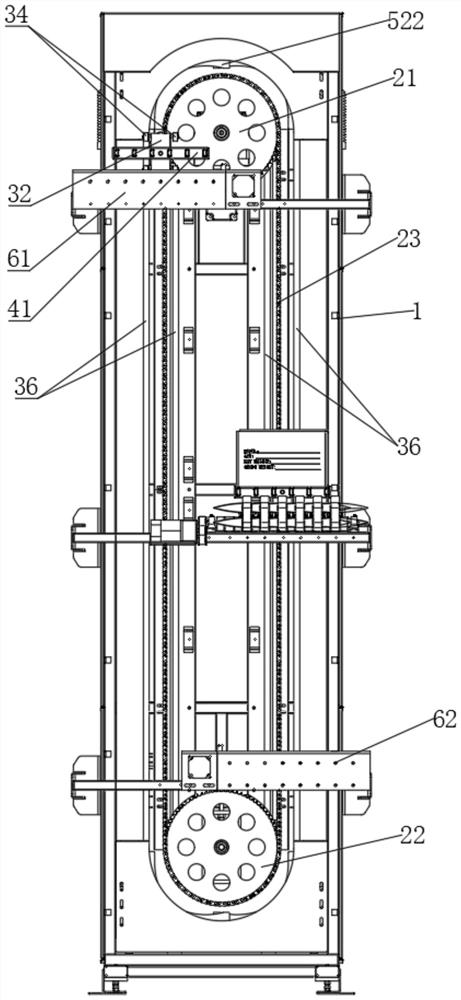

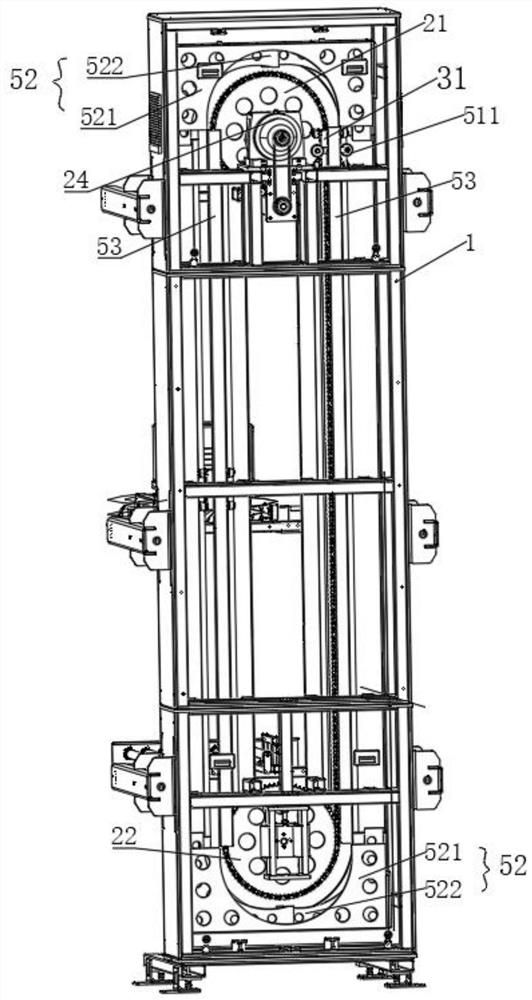

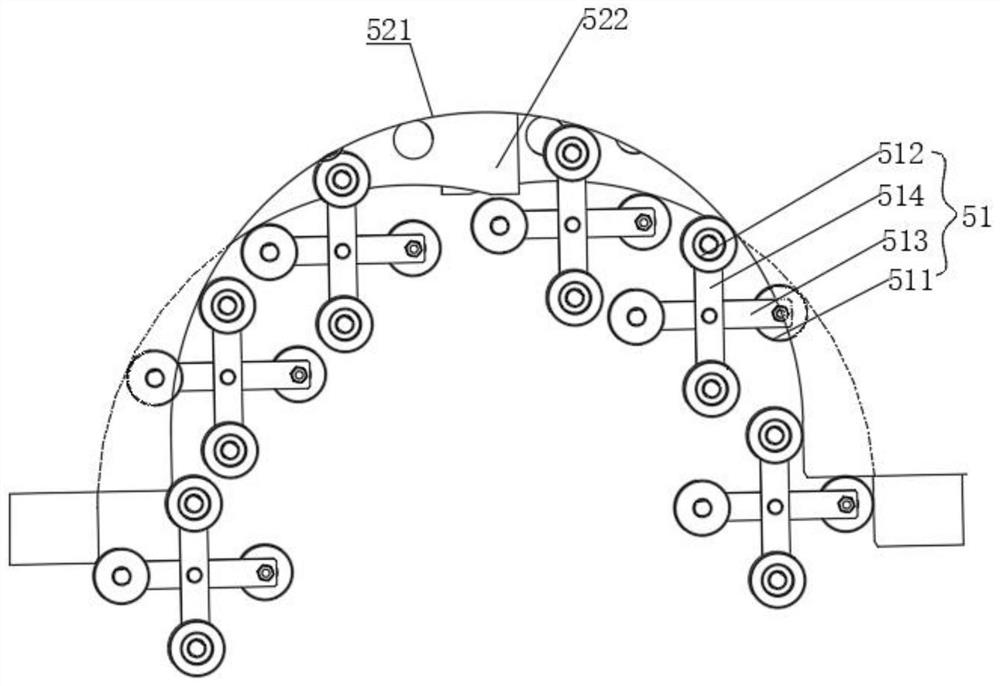

[0024] See figure 1 with figure 2 , This embodiment provides a continuous vertical automatic conveying device, which includes a frame 1, a drive mechanism arranged on the frame 1, a predetermined number of load components, a balance guide, a predetermined number of connecting parts, An upper loading station 61 and a lower loading station 62.

[0025] A predetermined number of universal wheels (not shown in the figure) are provided at the lower end of the frame 1, and each universal wheel is provided with a braking mechanism. The driving mechanism includes a driving wheel 21, a driven wheel 22, a driving chain 23, and a first motor 24. The driving wheel 21 and the driven wheel 22 are respectively arranged at the upper and lower ends of the frame 1. , The drive chain 23 is connected to the driving wheel 21 and the driven wheel 22, the first motor 24 is arranged behind the driving wheel 21, drivingly connected to the driving wheel 21, and the first motor 24 drives the The driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com