A vacuum low-temperature continuous drying method and equipment for municipal sludge

A municipal sludge, vacuum and low temperature technology, applied in separation methods, sludge treatment, chemical instruments and methods, etc., can solve the problems of inability to realize green production, low drying efficiency, high heat source cost, etc., and achieve simple structure and high drying efficiency High, uniform cloth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

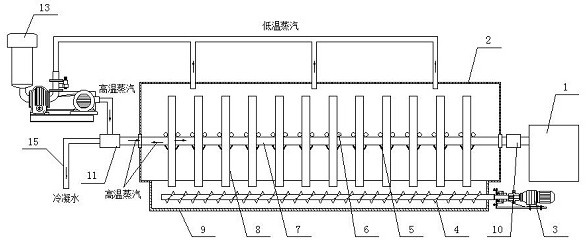

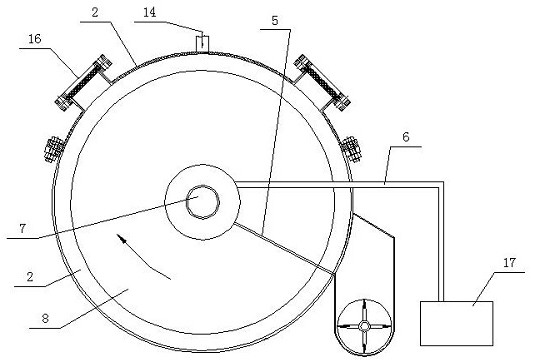

[0048] as attached figure 1 , 2 , 7, a kind of municipal sludge vacuum low-temperature continuous drying equipment of the present invention, its structure includes a relatively sealed drying shell 2, the drying shell 2 is provided with a horizontal rotating shaft 7, and a heating plate 8 is installed on the horizontal rotating shaft 7 , the heating plate 8 has a certain roughness, which is convenient for municipal sludge distribution. The side of the heating plate 8 is provided with a cloth assembly 6 and a scraper 5. The cloth assembly 6 and the scraper 5 are fixed on the drying shell 2. The inlet of the cloth assembly 6 is The pipe section is connected to the municipal sludge silo, and the outlet pipe section is provided with a municipal sludge outlet. Driven by the horizontal rotating shaft 7, the relative rotation occurs between the heating plate 8 and the cloth assembly 6 to lay the municipal sludge on the heating plate 8. on the disk;

[0049] The horizontal rotating s...

Embodiment 2

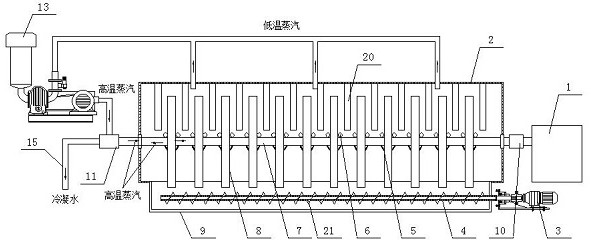

[0064] as attached Figure 1-4 , 7, on the basis of Embodiment 1, a semicircular heat radiation plate 20 is provided on the left and right sides of the upper half of the heating plate 8, the heat radiation plate 20 is a hollow structure, and the heat radiation plate 20 The arc surface is arranged on the inner wall of the arc drying shell 2 . The screw seal discharge assembly includes a U-shaped discharge casing 9, a discharge motor 3 and a discharge screw shaft 4 that is arranged in the U-shaped discharge casing 9 and connected with the discharge motor 3, and the discharge screw shaft 4 is provided with There are helical blades 21 . One or more of the discharge screw shaft 4, the screw blade 21 or the U-shaped discharge shell 9 is a hollow structure, and a heating medium passes through it.

Embodiment 3

[0066] as attached figure 1 , 2 , 4, 5, and 7, with reference to Embodiment 1 and Embodiment 2, only a semicircular heat radiation plate 20 is provided on the left and right sides of the upper half of the heating plate 8, and the heat radiation plate 20 is hollow structure, the arc-shaped surface of the heat radiation plate 20 is arranged on the inner wall of the arc-shaped drying shell 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com