Yarn fixing device and method for warping machine

A fixing device and warping machine technology, which is applied in the field of warping machines, can solve the time-consuming and labor-intensive problems of adjusting the tension force of multiple yarns, and achieve the effect of maintaining parallel movement, convenient control, and improving time-consuming and labor-intensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

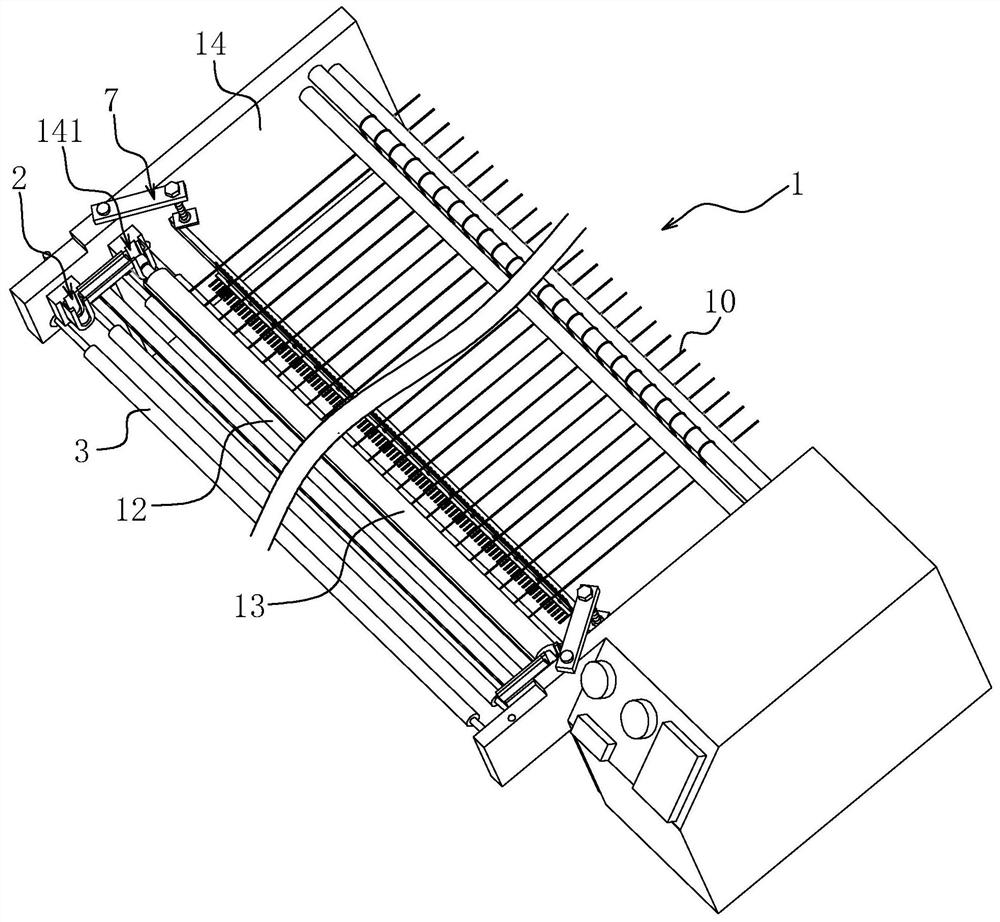

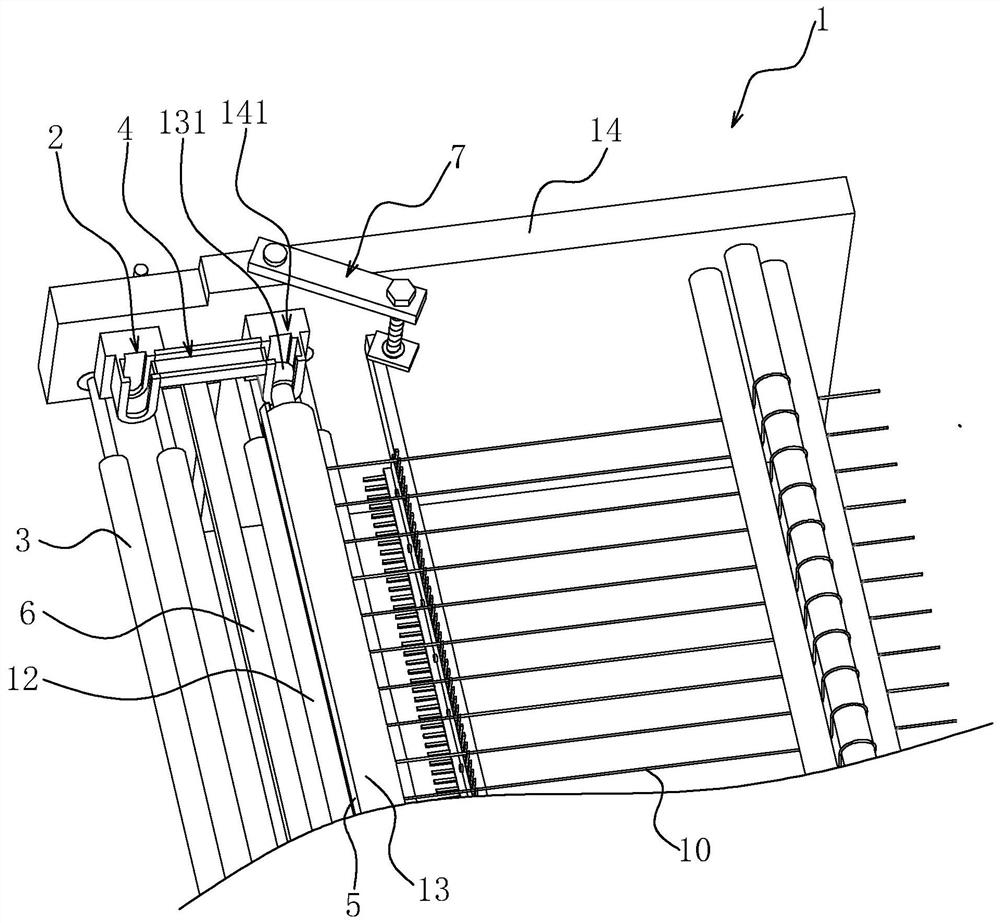

[0046] The following is attached Figure 1-7 The application is described in further detail.

[0047] The embodiment of the present application discloses a yarn fixing device for a warping machine. refer to figure 1 and figure 2 , applied to the warping machine 1, the warping area of the warping machine 1 is installed with two winding rollers 12 parallel to each other and a floral warp beam 13 for warping. When the flower warp shaft 13 is placed between the two rollers 12, the frame 14 of the warping machine 1 is fixedly connected with a limiting groove 141 for installing the first bearings 131 at both ends of the flower warp shaft 13, through the limiting groove 141 Make the floral warp beam 13 on the two winding rollers 12 not move horizontally during warping.

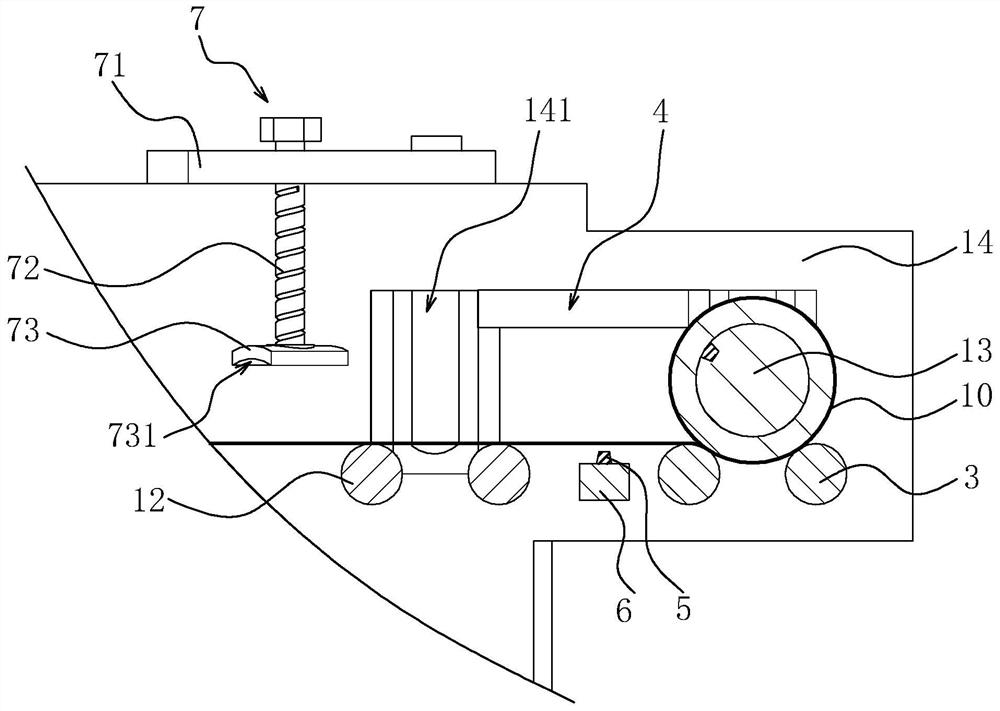

[0048] refer to figure 2 and image 3 , including a mounting groove 2 for installing the first bearing 131 of the warp beam 13, the mounting groove 2 is installed on the frame 14 of the warping machine 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com