Online cleaning device for vertical well oil pumping pipe

A technology for cleaning devices and oil sucking pipes, which is applied to drill pipes, casings, cleaning appliances, etc., can solve the problems of damage to the inner wall of oil sucking pipes, time-consuming and labor-intensive transportation of oil sucking pipes, and high cleaning costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

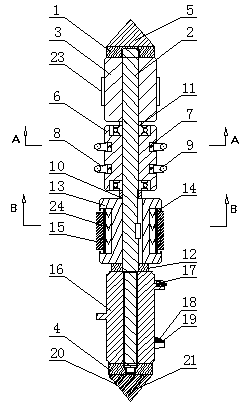

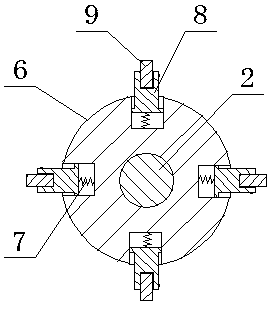

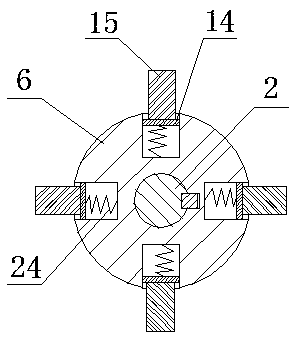

[0026] The on-line cleaning device for the oil extraction pipe of a vertical well is composed of an upper end cover 1, a central shaft 2, a counterweight 3, a centralizing mechanism, a cleaning mechanism, a transmission mechanism and a lower end cover 4; 1. The upper guide head 5 is fixedly installed on the upper end cover 1. The upper guide head 5 is in the shape of a pointed cone. The oil in the oil pipe acts as a shunt to reduce the resistance of the oil to the device. In operation, when the central shaft 2 rotates, the upper end cover 1 drives the upper guide head 5 to rotate.

[0027] The central shaft 2 below the upper end cover 1 is fitted with a counterweight 3 through the shaft shoulder 11, the counterweight 3 is cylindrical, and the traction ring 23 is symmetrically arranged on the counterweight 3, through the upper end cover 1 and the central shaft 2 The shaft shoulders 11 cooperate with each other to form a limit on the counterweight 3. The purpose of the counterw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com