Well point pipe structure and well point construction method

The technology of well point pipe and well point is applied in the field of well point pipe structure and well point construction, which can solve the problems of easy accumulation of filter material in the well point mouth part of the well point hole and inability to evenly fall into the well point hole, etc. To achieve the effect of improving the uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

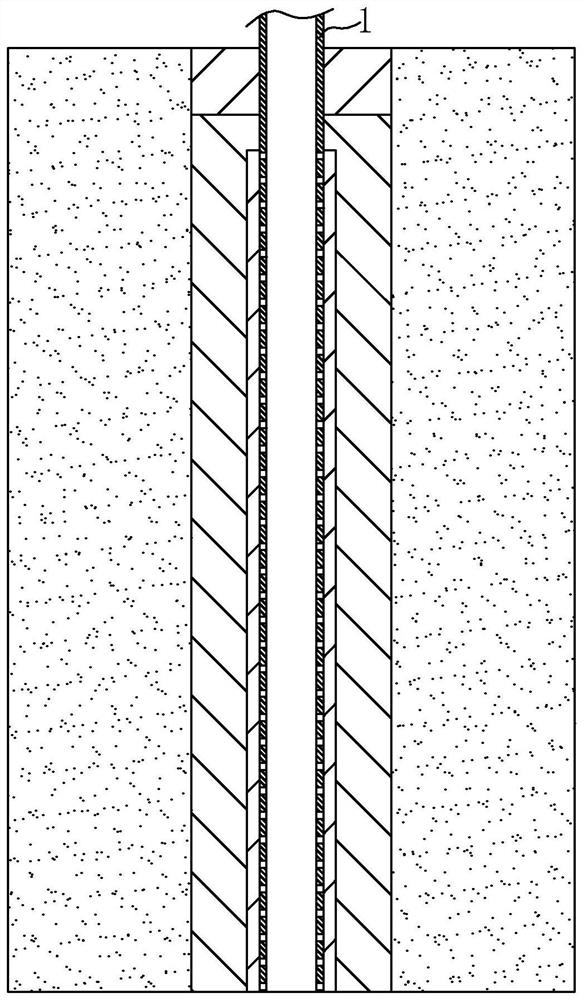

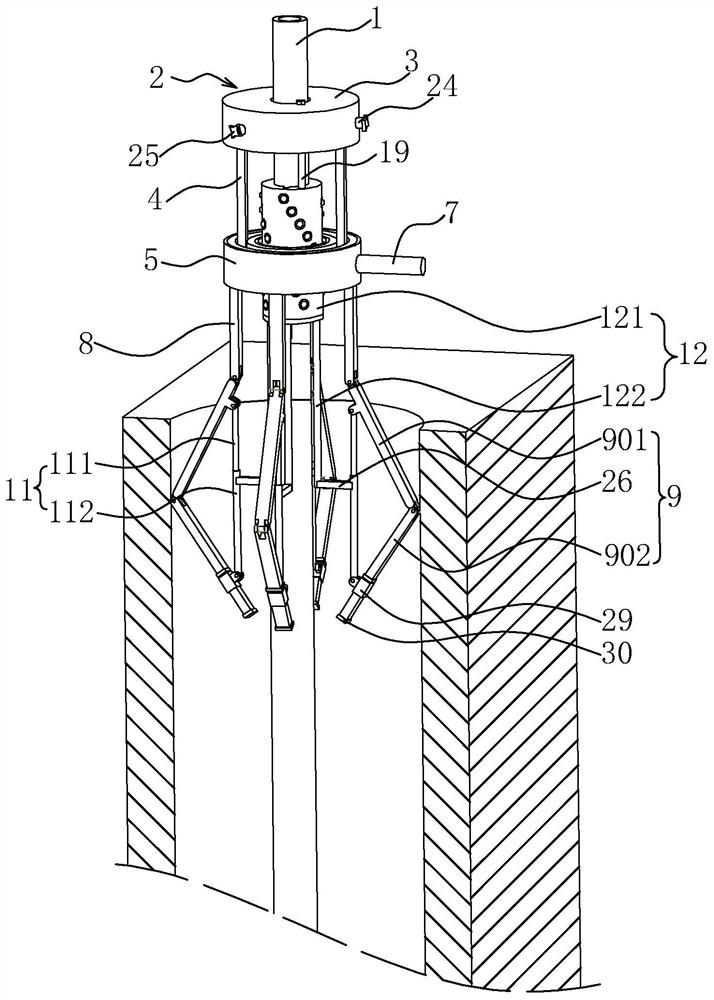

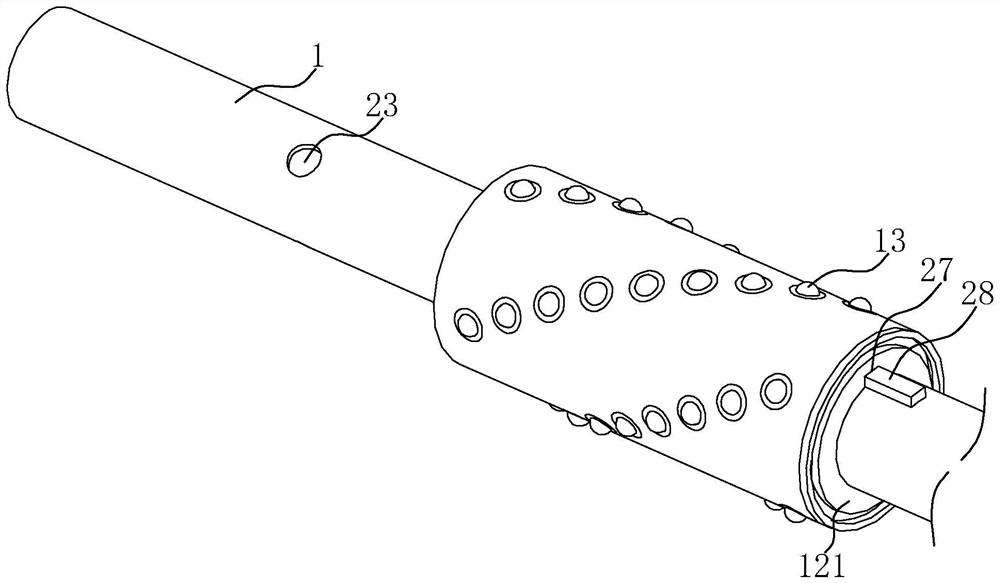

[0039] Contraction below Figure 2-7 Further detailed description of the present application.

[0040] See figure 2 For a well spot tube disclosed in the present application, including tubing 1 and agitation device 2. The agitation device 2 is disposed in the tubing body 1, first place the tube 1 into the well point hole, and then stir the filled filter material by agitation device 2, so that the filter material can be relatively uniformly removed into the well point hole, lowered filter. It is possible to stacked in the top of the well.

[0041] See figure 2 and Figure 3 The agitation device 2 includes a mount 3, and the mounting sleeve 3 is set in the outer peripheral side of the tube body 1 close to the top portion. The tubular body 1 is uniformly spaced apart from the outer peripheral side, and the mounting sleeve 3 is screwed with the screw 24, and the screw 24 is fixed to the tubular body 1 to secure the knob 25. When using the rotary knob 25, the drive screw 24 is inserted i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com