Overall overhead structure of fabricated ground

An overhead structure, prefabricated technology, applied in the direction of floors, building structures, local raised floors, etc., can solve problems such as poor overall bearing capacity, easy tilting of brackets, damage to decorative panels, etc., to improve construction efficiency and improve integrity. And the effect of stability, easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

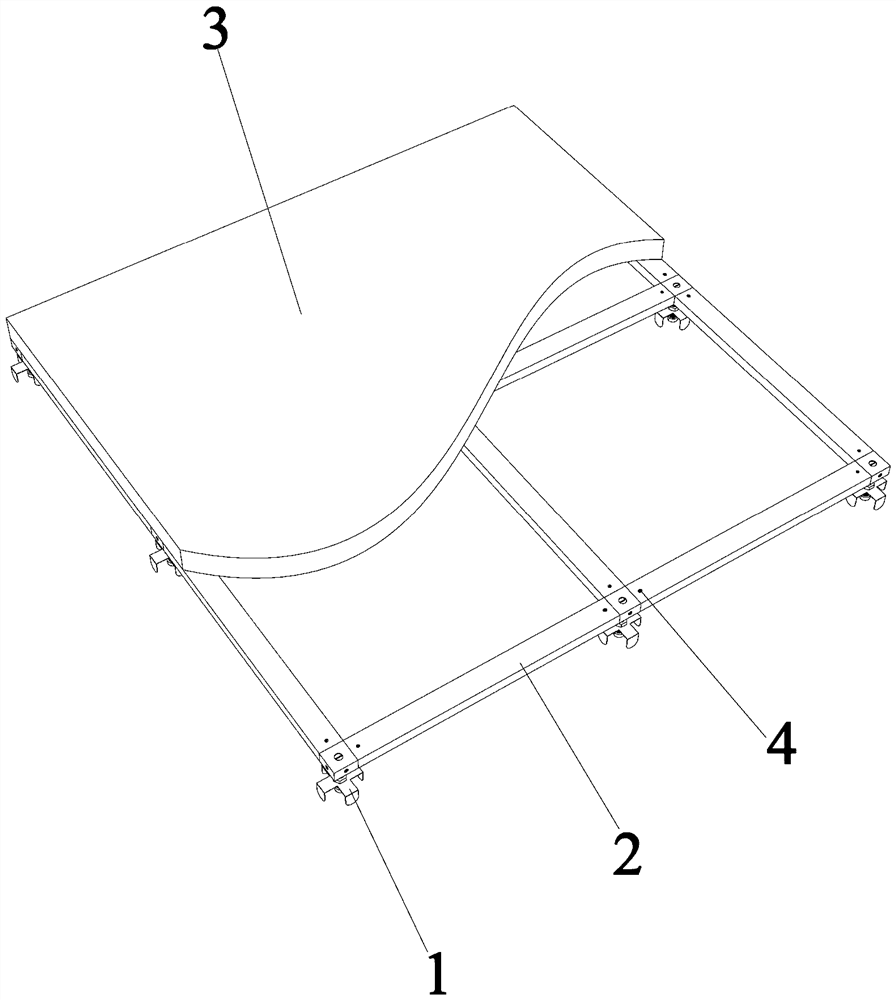

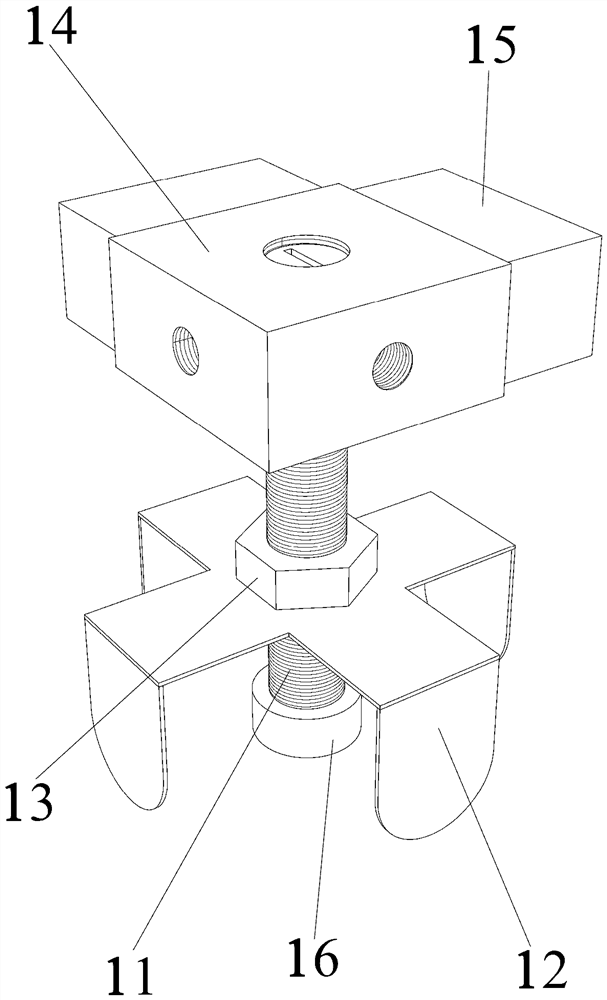

[0036] see figure 1 figure 2 , the figure shows an assembled ground overall overhead structure provided by Embodiment 1 of the present invention, including: a leveling load-bearing assembly 1, which includes an adjusting screw 11, which is sleeved on the adjusting screw 11 from bottom to top. The stabilizer 12, the fixing nut 13, the bearing platform 14 and the connecting piece 15 arranged on the side of the bearing platform 14; the frame keel 2, whose side is "C" shaped, and the end of the frame keel 2 is set on the connecting piece 15; leveling There are multiple load-bearing parts 1, multiple frame keels 2, multiple leveling load-bearing components 1 connect the frame keels 2 to form a closed frame structure; on the surrounding structural frame.

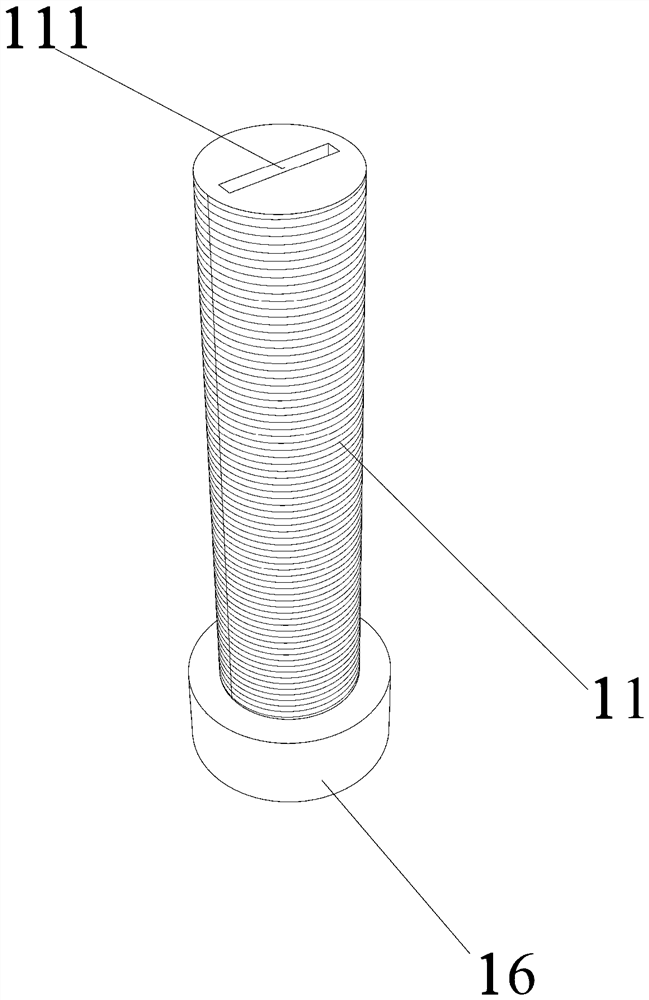

[0037] Wherein, the top of the adjusting screw 11 is provided with an adjusting groove 111, and a screwdriver is inserted into the adjusting groove 111 and rotated to adjust the vertical height of the whole overhead structure. ...

Embodiment 2

[0046] see Figure 2 to Figure 3 , the figure shows a prefabricated ground overall overhead structure provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following improved technical solutions: leveling the load-bearing components 1 also includes a support block 16, which is arranged at the bottom of the adjustment screw 11; the adjustment screw 11 is provided with an external thread, and the top of the adjustment screw 11 is provided with a "one"-shaped adjustment groove 111. Through the setting of the above structure, the "one"-shaped adjusting groove 111 is exposed on the top of the adjusting screw 11. When installing, use a screwdriver to align with the adjusting groove 111 on the top of the adjusting screw and rotate to achieve the purpose of leveling the overall overhead structure.

Embodiment 3

[0048] see Figure 2 to Figure 5, the figure shows a prefabricated ground overall overhead structure provided by Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following improved technical solutions: the stabilizer 12 includes A cross-shaped bottom plate 121 and a "U"-shaped support plate 122, the four ends of the cross-shaped bottom plate 121 extend vertically downward to form a support plate 122; the center of the bottom plate 121 is provided with a circular limiting hole 123, and the inner diameter of the limiting hole 123 It matches the outer diameter of the leveling screw rod 11; the center of the carrying platform 14 is provided with an adjusting hole 141, and the adjusting hole 141 is provided with an internal thread matched with the adjusting screw rod 11; the adjusting hole 141 is a through hole; the carrying platform 14 is square as a whole. type, the central position of its side is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com