Drilling device for coal mine underground gas extraction

A gas extraction and drilling device technology, which is applied to supporting devices, drilling equipment and methods, and earth-moving drilling, etc., can solve the problems of inconvenient handling of mud, inconvenient mud collection, and large shaking of drill pipe. Perfect function, improve cleaning effect, reduce the effect of shaking amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

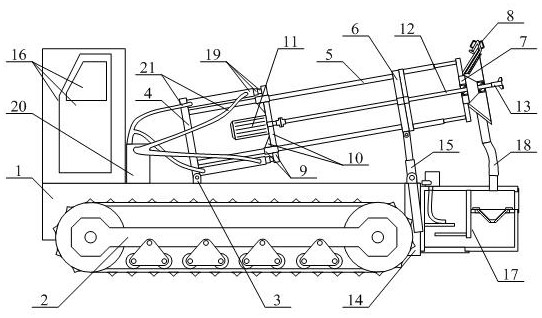

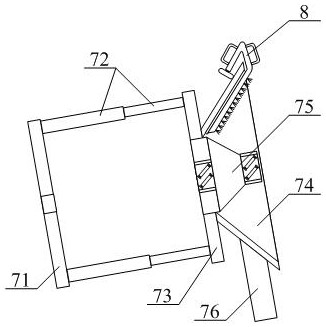

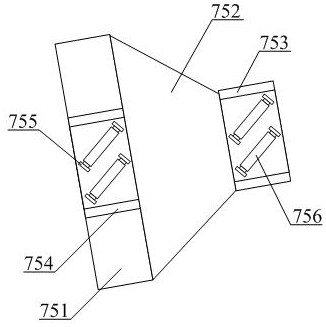

[0035] as attached figure 1 and attached figure 2 As shown, a drilling device for underground gas drainage in coal mines includes a drilling vehicle frame 1, a drilling vehicle crawler 2, a lug plate 3, a mounting seat 4, a support column 5, a top mounting plate 6, a telescopic Mud collection rack structure 7, mud cleaning rack structure 8, moving pipe 9, sliding mounting plate 10, drilling motor 11, rotary drill pipe 12, drill bit 13, installation groove 14, adjusting cylinder 15, cockpit 16, mud filter sedimentation box Structure 17, connecting hose 18, hydraulic cylinder 19, hydraulic pump station 20 and oil inlet and outlet pipes 21, the drilling truck crawler 2 is respectively installed on the lower front and rear ends of the drilling truck frame 1; the lug plate 3 The bolts are respectively connected to the upper right side of the drilling vehicle frame 1 and the upper left position of the drilling vehicle frame 1 and the lower part of the top mounting plate 6; the mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com