Auxiliary curing device for epoxy floor laying

A curing device and epoxy floor technology, applied in the direction of drying solid materials, drying gas arrangement, lighting and heating equipment, etc., can solve the problem of not speeding up the drying time of the ground, reducing the efficiency of epoxy floor laying, and affecting the efficiency of epoxy floor Curing and other issues to achieve the effect of improving laying efficiency, speeding up drying time, and saving time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

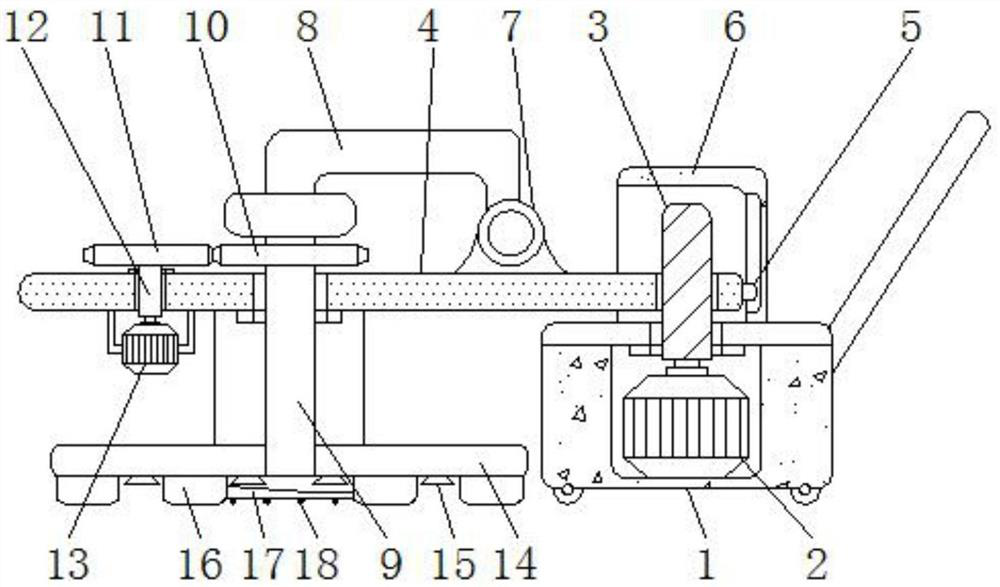

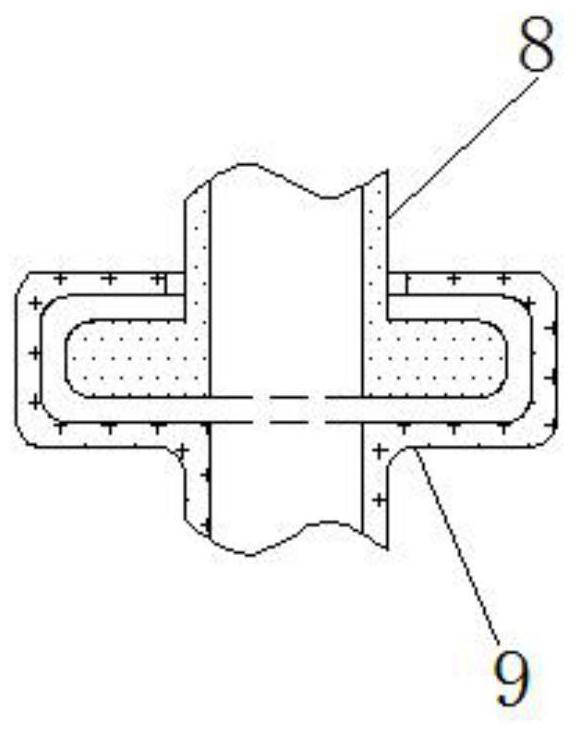

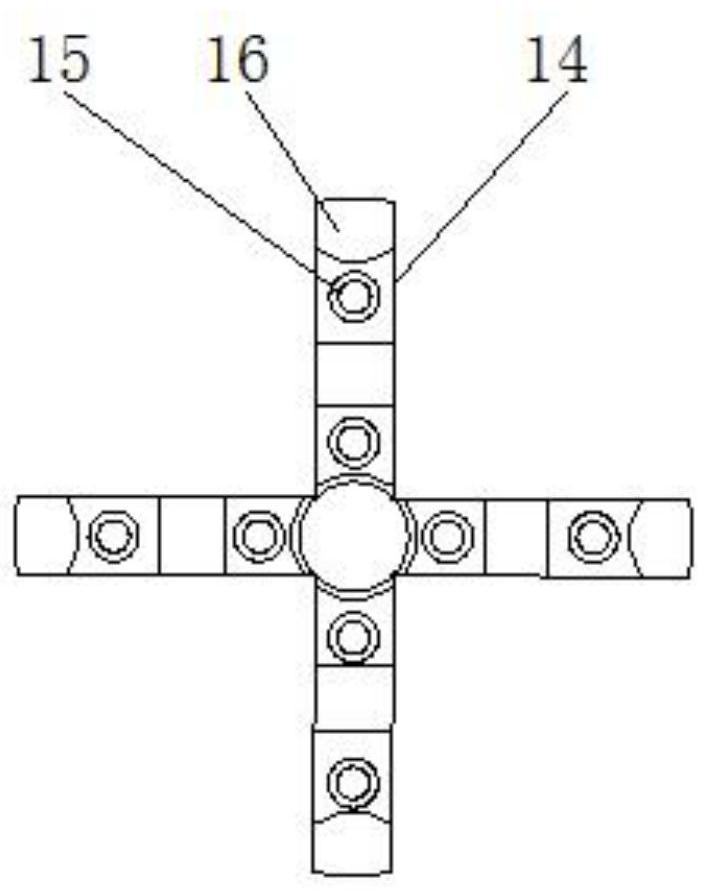

[0028] from Figure 1-6 It can be seen that a kind of auxiliary curing device for epoxy floor laying in this embodiment includes a base 1, a blower 7 and a drive motor 13, the inside of the base 1 is fixed with a servo motor 2 by bolts, and the output end of the servo motor 2 Connected to the screw rod 3, the outer threaded end of the screw rod 3 is connected to the mounting plate 4, the right side of the mounting plate 4 is welded to the limit block 5, the upper side of the base 1 is installed with a protective frame 6, and the blower 7 is fixedly installed on the mounting plate 4, the output end of the blower 7 is provided with an air delivery pipe 8 and a connecting pipe 9 in turn, the blower 7 communicates with the connecting pipe 9 through the air delivery pipe 8, and one end of the connecting pipe 9 runs through the mounting plate 4 and is connected with a cleaning plate 14, The bottom of the cleaning plate 14 is provided with an air spray head 15 and cleaning cotton 16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com