Wharf intelligent point inspection method and system based on unmanned aerial vehicle robot

A technology of unmanned aerial vehicles and robots, which is applied in the field of dock inspection, can solve problems such as equipment safety hazards, reduce equipment reliability, and damage to motor gearboxes, and achieve the effects of ensuring integrity, ensuring life, and reducing wireless signal interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

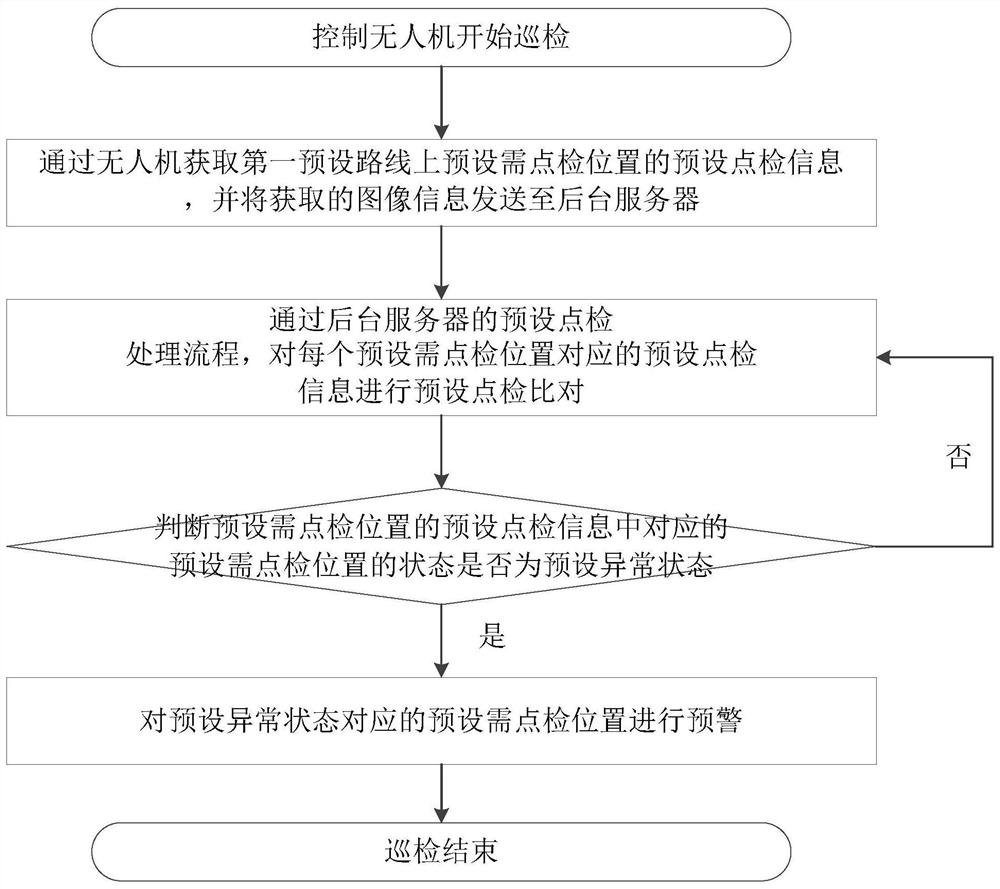

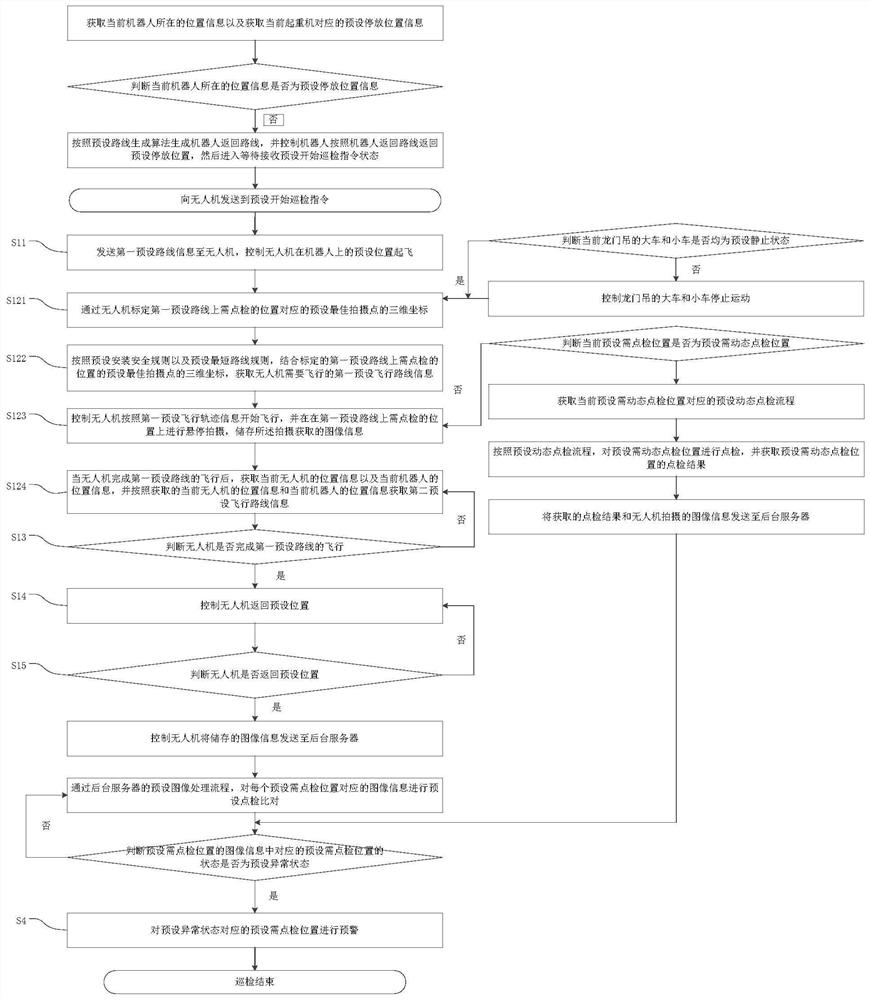

[0061] This embodiment provides a kind of dock intelligent inspection method based on unmanned aerial vehicle robot, such as Figure 1 to Figure 2 as shown,

[0062] The drone robot includes a drone and a robot, the drone is carried on the robot, the robot includes a body, a first wireless communication device, and the drone includes a fuselage, a control component and a second wireless communication device. Communication equipment; the method comprises the steps of:

[0063] S1: Obtain the preset check information of the preset position to be checked on the first preset route through the drone, and send the acquired preset check information to the background server, the preset check information includes preset The image information, sound information, temperature information of the location to be checked, and the stress, vibration and other information of the current equipment sent by the preset IoT sensor set on the equipment;

[0064] S2: Through the preset check processi...

Embodiment 2

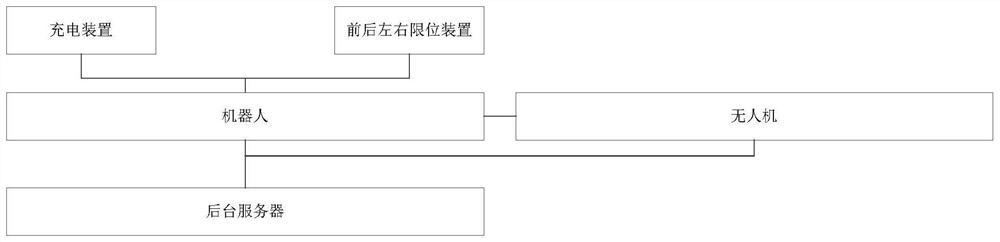

[0124] This embodiment provides a kind of terminal intelligent inspection system based on unmanned aerial vehicle robot, such as image 3 As shown, the system includes:

[0125] An unmanned aerial vehicle robot, the unmanned aerial vehicle robot includes an unmanned aerial vehicle and a robot, the unmanned aerial vehicle is carried on the robot, the robot includes a body, a first wireless communication device, and the unmanned aerial vehicle includes a fuselage, a control Components and a second wireless communication device; the UAV is used to obtain the preset check information of the preset position to be checked on the first preset route, and send it to the background server through the preset information sending method, and the preset The information sending method includes the preset wireless communication method of the UAV and the preset indirect communication method of the robot;

[0126] Further, the robot is not only the current artificial intelligence robot, but al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com