Radiation protection structure for spent fuel transport ship

A technology for radiation protection and transportation of ships, which is applied to ship accessories, transportation and packaging, reactors, etc., and can solve the problems of increased radiation exposure levels of crew members and high radiation levels of ships

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

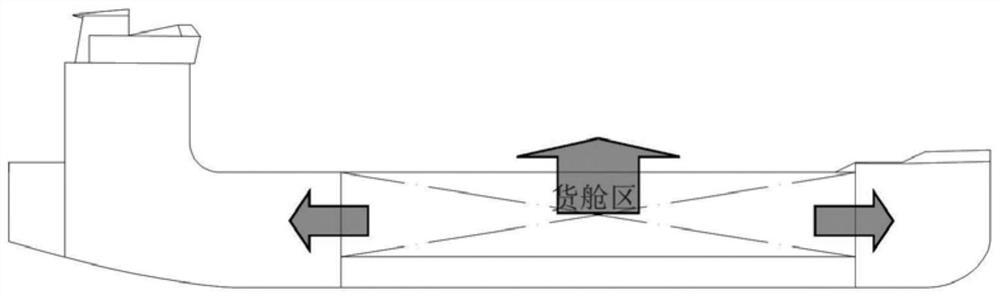

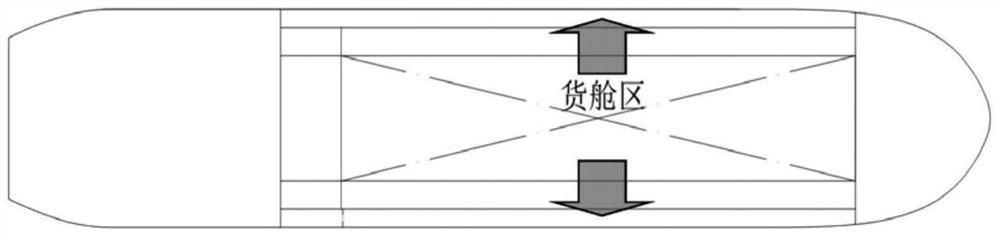

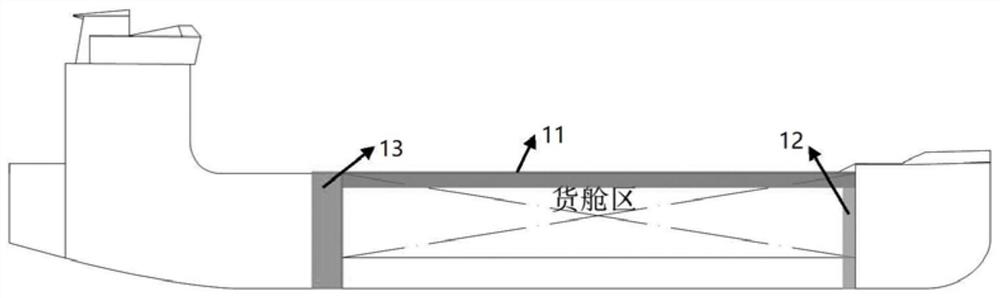

[0041] Such as figure 2 As shown, the radiation protection structure of the spent fuel transport ship of the present invention includes a cargo hold area, the cargo hold area has at least one cargo hold 10 capable of carrying one or more spent fuel packages, the cargo hold hatch cover of the hold 10, and the bow transverse bulkhead 1. The cargo hold near the stern bulkhead and the bulkheads on both sides of the cargo hold are provided with a shielding body, which is composed of one or more shielding materials of steel, concrete, polyethylene and fresh water in a layered combination.

[0042] refer to figure 1 with figure 2 As shown, the spent fuel transport ship is provided with a cargo hold 10 for loading spent fuel packages, and there may be one or more cargo holds 10, which can carry one or more spent fuel packages. Radioactive particles penetrate the cargo package and reach the interior area of the cargo hold, and further reach other areas of the ship through the hat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com