Automatic pin inserting device for transformer shell

A technology of pin insertion device and transformer, which is applied in the direction of inductance/transformer/magnet manufacturing, electrical components, circuits, etc., can solve the problems of energy consumption, low efficiency, and low yield, so as to reduce manpower input, improve efficiency, Health damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the technical solutions and beneficial effects of the present invention clearer, the implementation manners of the present invention will be further explained in detail below.

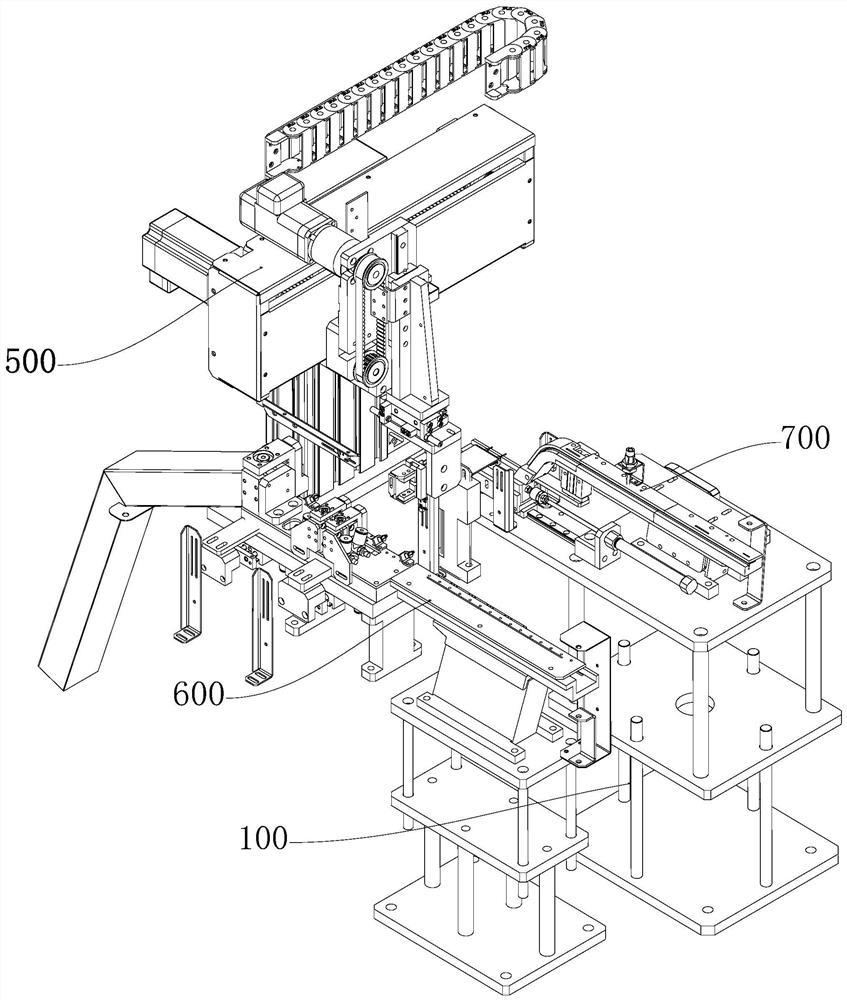

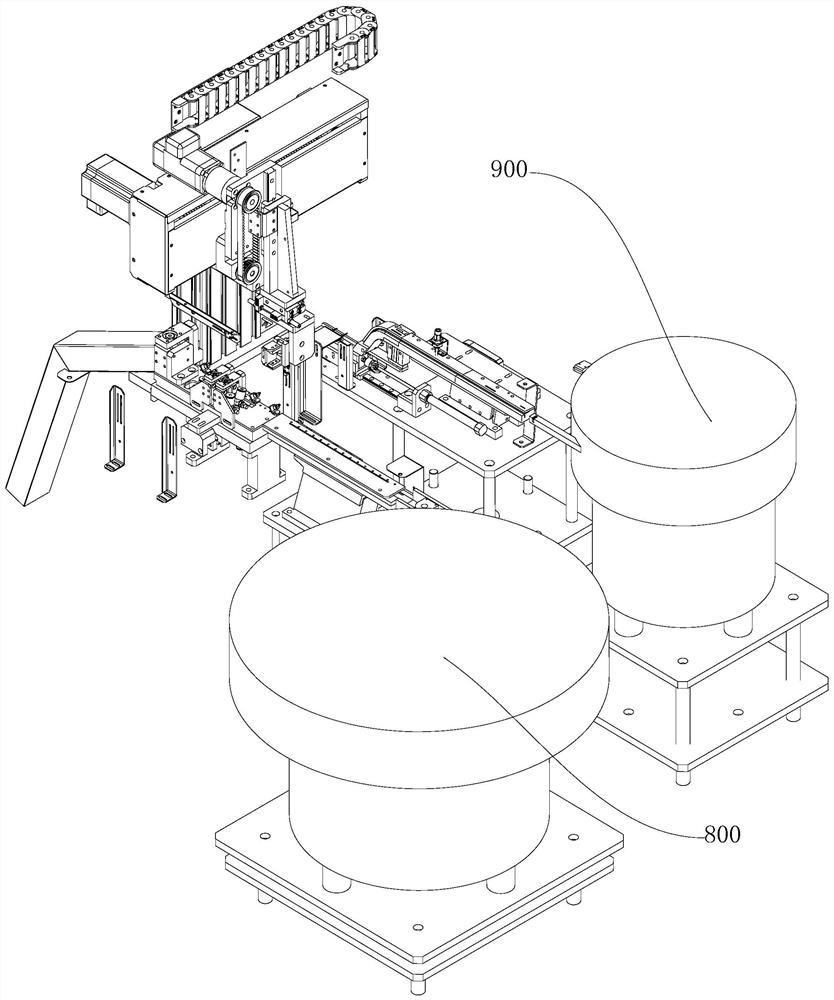

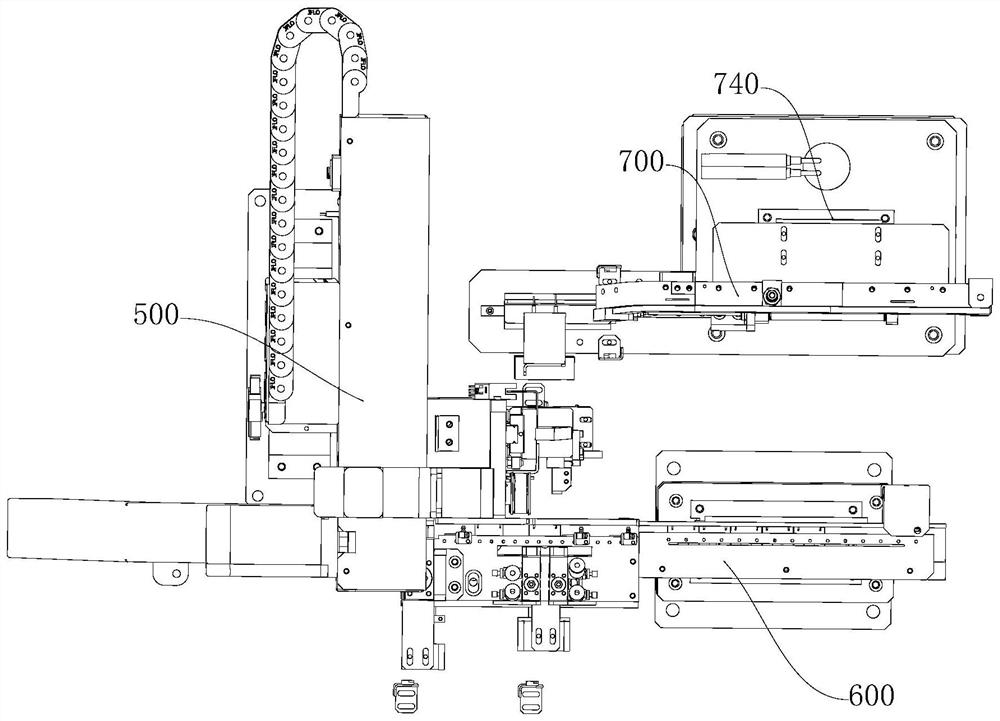

[0049] Such as figure 1 As shown, the automatic pin insertion device for the transformer housing includes a frame body 100 , a pin vibrating plate 900 and a shell vibrating plate 800 . The frame body 100 is used to realize the installation of various components, and can be constructed by using aluminum-plastic profiles. Vibrating plate, also known as rotating vibrating plate, is an auxiliary equipment for automatic assembly machinery, which can discharge various products in an orderly manner. It can cooperate with automatic assembly equipment to assemble all parts of the product into a complete product. In the present invention, the rotation of the vibrating plate is used to realize the sorting of the pins and the housing, and then input to the pin track 700 and the shell trac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com