Chemical tail gas dedusting spraying device

A technology of spraying device and chemical tail gas, which is applied in the direction of transportation and packaging, chemical instruments and methods, and filtration of dispersed particles, which can solve the problems of low flue gas treatment efficiency and inability to remove dust, and achieve high-efficiency absorption and ensure network The effect of unimpeded board and efficient dust filtration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

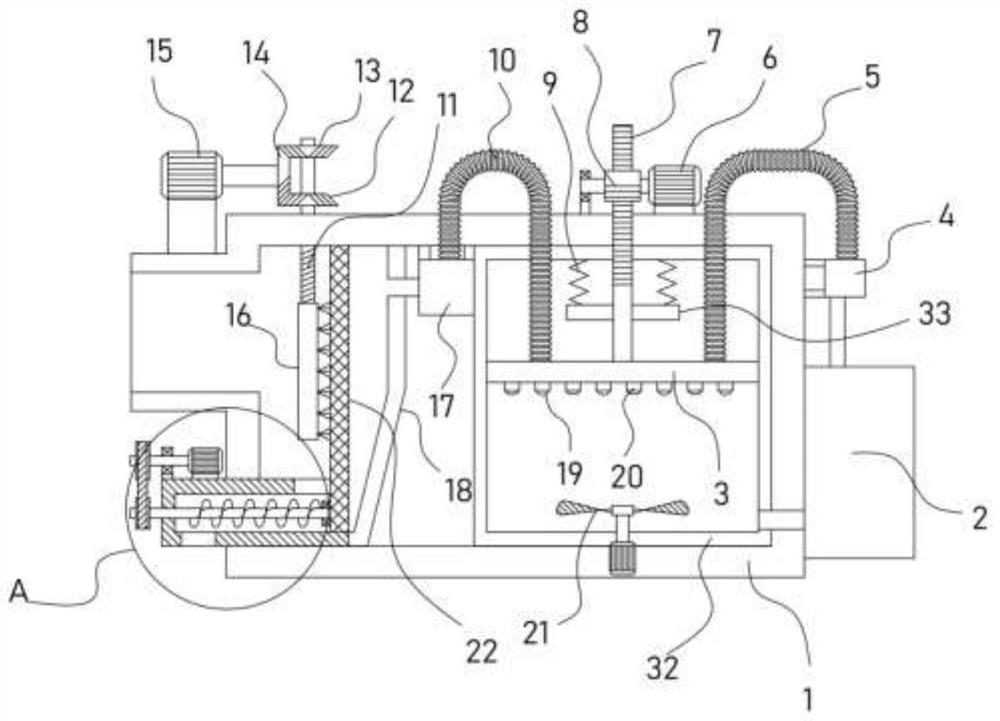

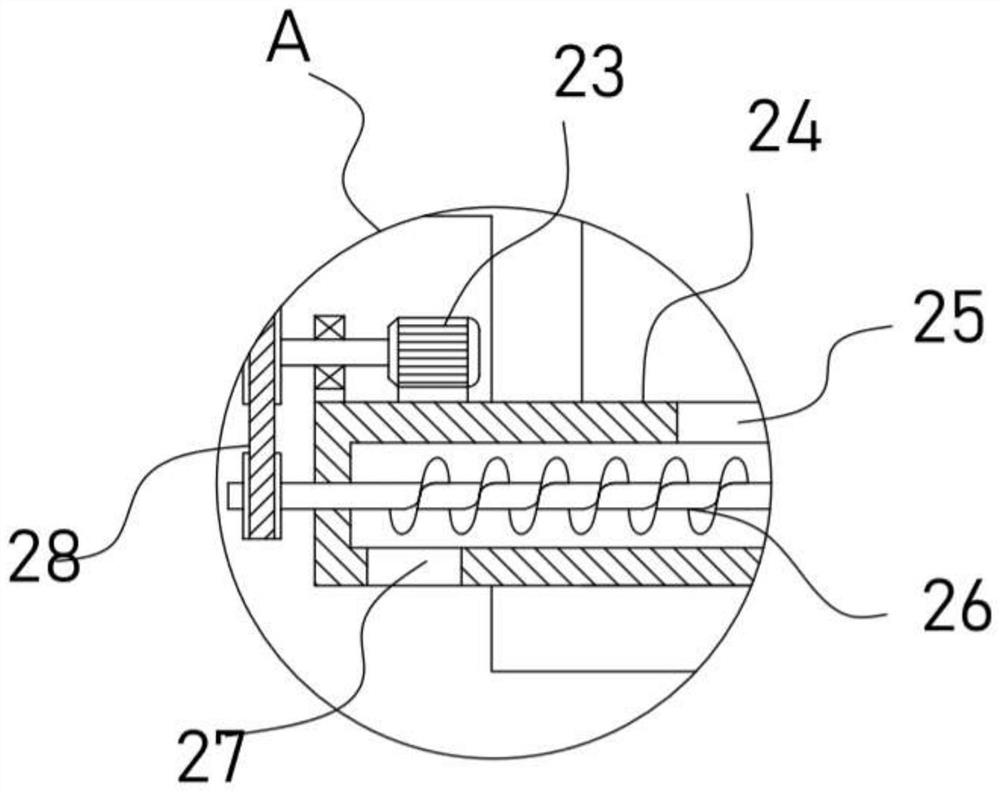

[0023] see Figure 1-4 , a chemical tail gas dedusting spraying device, comprising a support frame 1, a dust removal box 18 and an absorption box 32 are arranged in the support frame 1, a dust filter screen 22 is vertically fixed in the dust removal box 18, and a dust filter screen 22 is fixed on the top of the support frame 1 The motor II15 is driven and connected with a cleaning mechanism for cleaning the dust filter screen 22. The dust removal box 18 is provided with a conveying mechanism for conveying the dust. The top of the support frame 1 is fixed with a motor I6 and a motor I6. The upper drive is connected with a vertical reciprocating mechanism, and the vertical reciprocating mechanism is driven and connected with an air jet disc 3 communicating with the inside of the dust removal box 18. The side wall of the support frame 1 is fixed with a liquid medicine tank 2, which is connected to a The spray mechanism in the absorption box 32.

[0024] The exhaust gas of chemic...

Embodiment 2

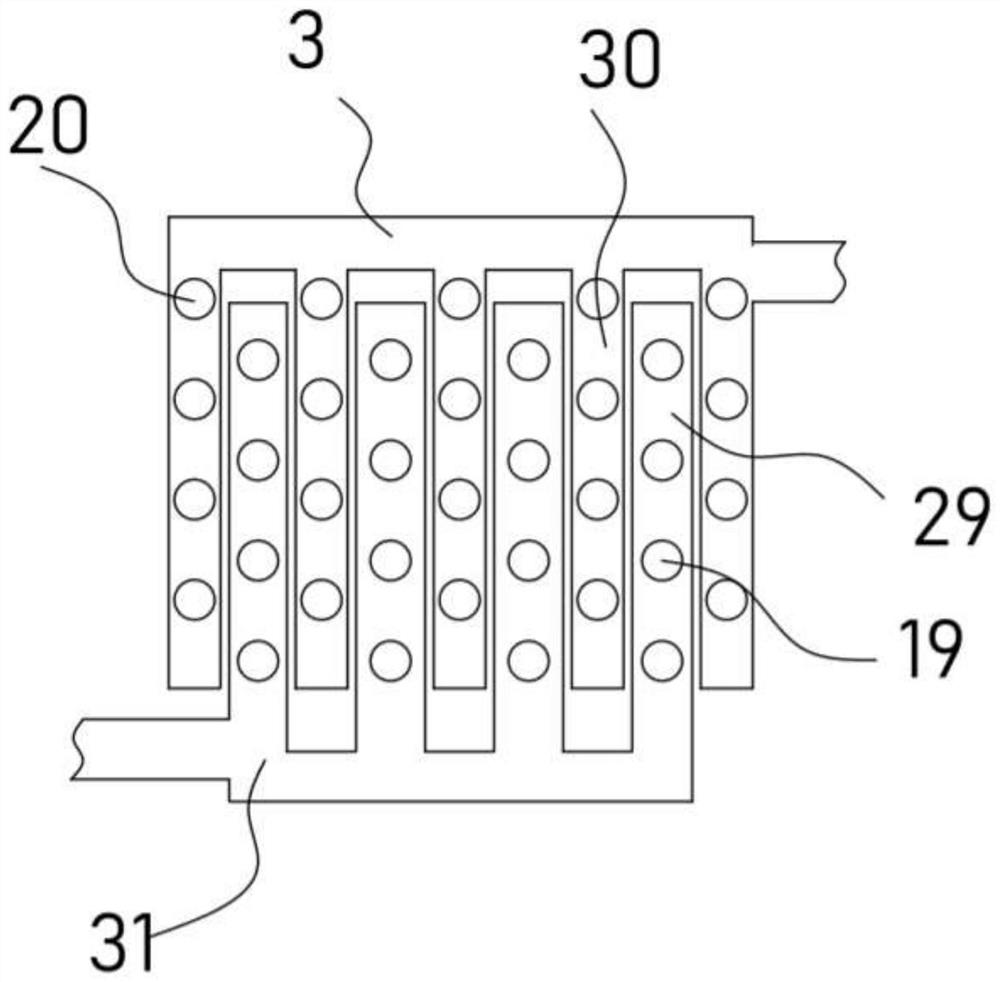

[0030] On the basis of Embodiment 1, in addition, the delivery pump 17 communicating with the dust removal box 18 is fixed on the support frame 1, and the bellows II10 communicating with the air injection disc 3 is installed at the outlet end of the delivery pump 17, and the equal intervals on the delivery air injection disc 3 Several extension pipes II30 are installed, and several smoke nozzles 20 are evenly installed on the extension pipes II30.

[0031] The conveying pump 17 pumps the exhaust gas in the dust removal box 18, and the exhaust gas enters the interior of the gas injection plate 3 along the bellows II10, and finally sprays out from the smoke nozzle 20. The spray mechanism includes a lift pump 4 connected to the liquid medicine tank 2 , a bellows I5 is installed on the lifting pump 4, a liquid medicine spray plate 31 is installed on the bellows I5, and several extension pipes I29 interlaced with the extension pipe II30 are installed on the liquid medicine spray pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com