Capsule type glue supply and control spray gun

A spray gun and capsule technology, which is applied in the field of capsule-type glue supply and control glue spray guns, can solve the problems of material leakage, air leakage, unreliable use, nozzle caking, etc. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

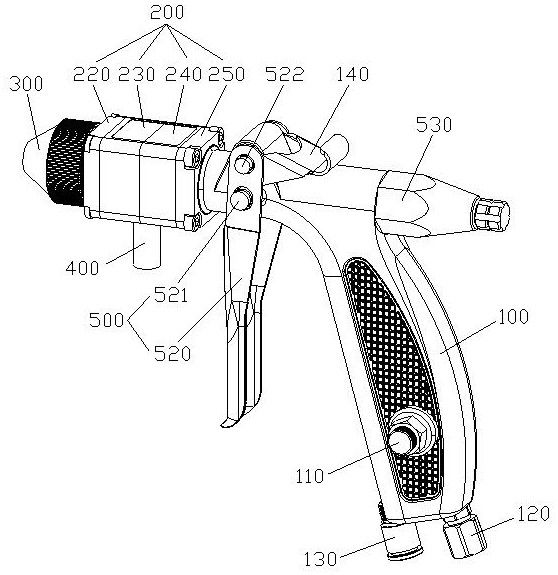

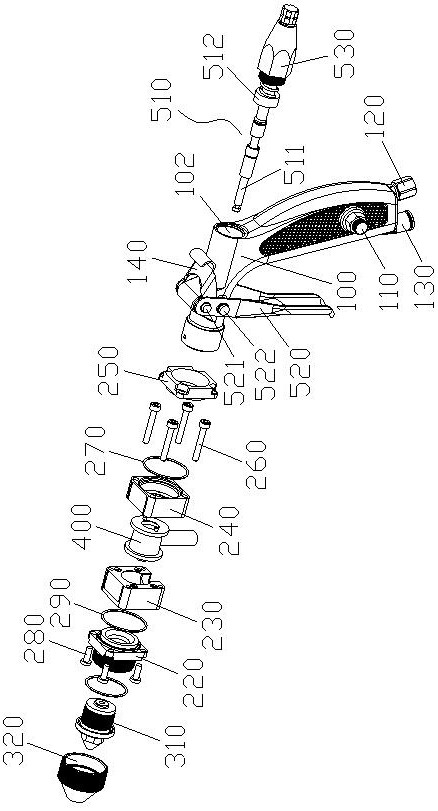

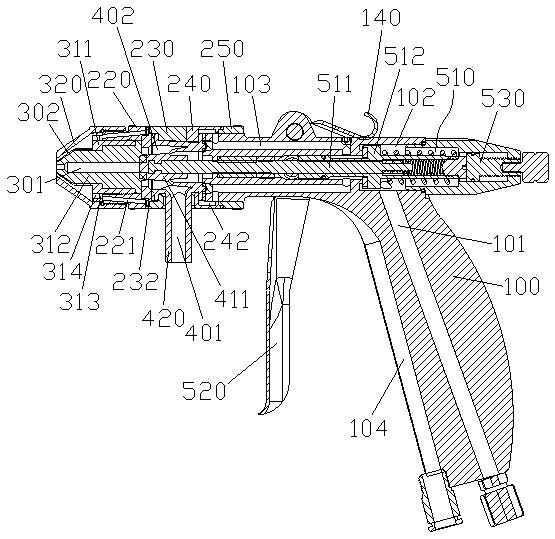

[0024] Embodiment one: if Figure 1~3 As shown, a capsule-type spray gun for glue supply and glue control includes a gun body 100 (the material is metal), and the gun body 100 is provided with an air inlet passage 101 and a valve chamber 102 (or air outlet chamber) connected in sequence. and the first air outlet channel 103, the air outlet end of the gun body 100 is connected with an atomizing device 300 through a fixing device 200, and the atomizing device 300 is provided with a hard plastic glue outlet channel 301 and a second air outlet channel 302, so The air outlet direction of the second air outlet channel 302 and the glue outlet direction of the hard plastic glue outlet channel 301 intersect in front of the atomizing device 300, and the fixing device 200 is provided with a first air outlet channel 103 and a second air outlet channel 302. The transitional air passage 201, the elastic plastic capsule 400 is installed in the fixing device 200, the elastic plastic capsule 4...

Embodiment 2

[0026] Embodiment two: if Figure 1~3 As shown, a capsule type spray gun for glue supply and glue control, the difference of the first embodiment is that: the glue inlet end of the glue inlet channel 401 is exposed outside the gun body 100, so that it is convenient to connect the glue delivery pipe through the pipe joint.

Embodiment 3

[0027] Embodiment three: as Figure 1~5 As shown, a capsule-type spray gun for glue supply and glue control, the difference between the first and second embodiments is that the fixing device 200 includes a front cover 220 (made of metal), a front fixing seat 230 (made of metal) , rear fixing seat 240 (its material is metal) and back cover 250 (its material is metal), and described back cover 250 is fixedly set on the gas outlet end of gun body 100, and the rear end of described rear fixing seat 240 is set on The air outlet end of the gun body 100 is fixedly and sealingly connected with the rear cover 250, the rear end of the front fixing seat 230 is fixedly and sealingly connected with the front end of the rear fixing seat 240, and the elastic plastic capsule 400 is fixedly installed on the front fixing seat 230 and the rear Between the fixing seats 240 , the front cover 220 is fixedly and sealingly connected with the front end of the front fixing seat 230 .

[0028]In this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com