Building steel pipe derusting device

A technology for steel pipes and construction, applied in the field of construction steel pipe rust removal devices, can solve problems such as wasting energy, and achieve the effects of reducing wear, increasing applicability, and increasing practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

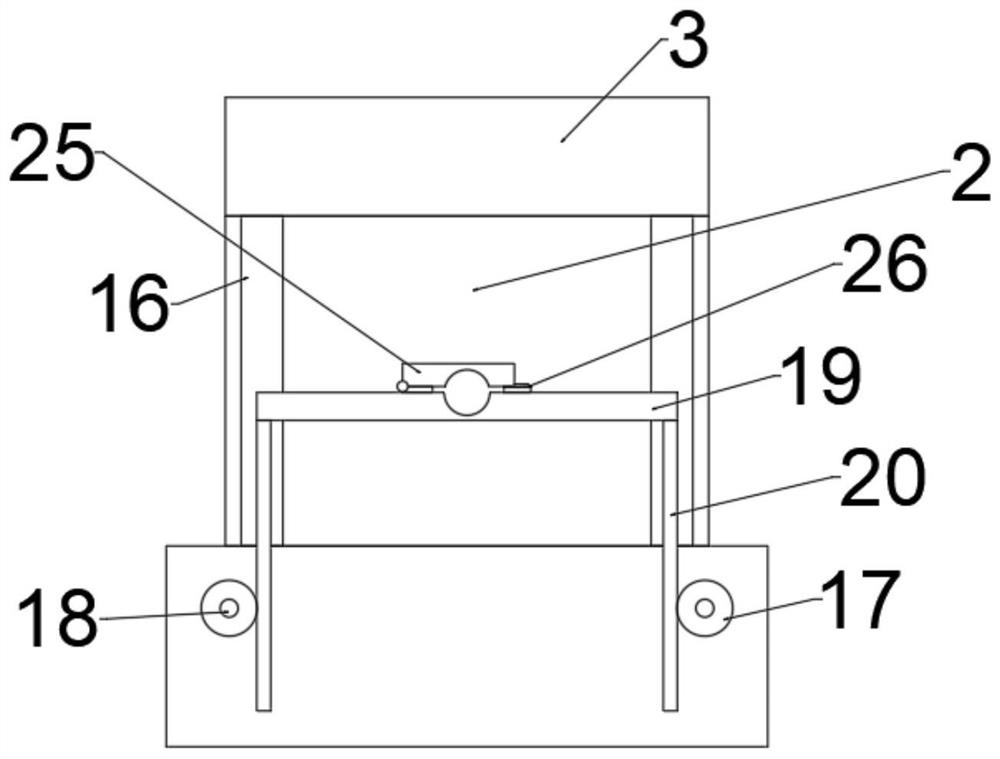

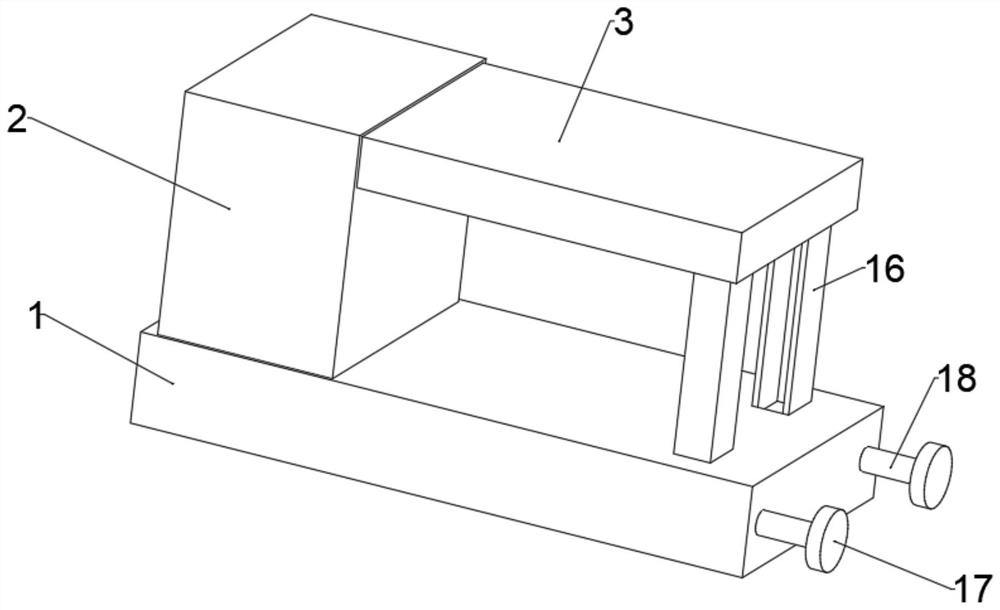

[0033] refer to Figure 1 ~ Figure 3, a construction steel pipe derusting device, comprising a bottom plate 1, a support box 2 is connected with bolts on the upper left side of the bottom plate 1, a top box 3 is connected with bolts on the upper right side of the support box 2, and the top box 3 is far away from the bottom of one end of the support box 2 There are several support columns 16 connected by bolts, and a placement plate 19 is arranged between the two support columns 16. One end of the support columns 16 away from the top box 3 is fixedly connected to the bottom plate 1, and the bottom left side of the support box 2 is bolted to a first The fixed plate 4, the upper bolt of the first fixed plate 4 is connected with the rotating motor 5, the output end shaft of the rotating motor 5 is connected with the rotating shaft 6, the upper axis of the rotating shaft 6 is fixed with the first driving gear 7, and the rotating shaft 6 runs through the support box 2, the end of th...

Embodiment 2

[0041] refer to Figure 4 ~ Figure 5 , a construction steel pipe derusting device. Compared with Embodiment 1, this embodiment is provided with a clamping mechanism in the clamping block 15. The clamping mechanism includes an adjusting shaft 32, a driving helical gear 33, a driven helical gear 34, a second Two power transmission shafts 35, the second driving gear 36, the second driven gear 27, the third screw mandrel 28, the third bearing seat 37, the fifth fixed plate 38 and the clamping plate 39, the surface of the clamping block 15 is rotatably connected with Several adjusting shafts 32, the lower shaft of the adjusting shaft 32 is fixed with a driving helical gear 33, the right side of the driving helical gear 33 is meshed with a driven helical gear 34, and the central axis of the driven helical gear 34 is fixed with a second transmission shaft 35 , the middle part of the second transmission shaft 35 is provided with a threaded structure, the second transmission shaft 35 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com