Chemical mechanical polishing equipment and application method

A technology of chemical machinery and equipment, which is applied in the field of chemical mechanical polishing equipment, can solve the problems of changing the ejection amount of polishing liquid and low polishing efficiency, and achieve the effects of improving practicability, improving polishing efficiency, and increasing ejection amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

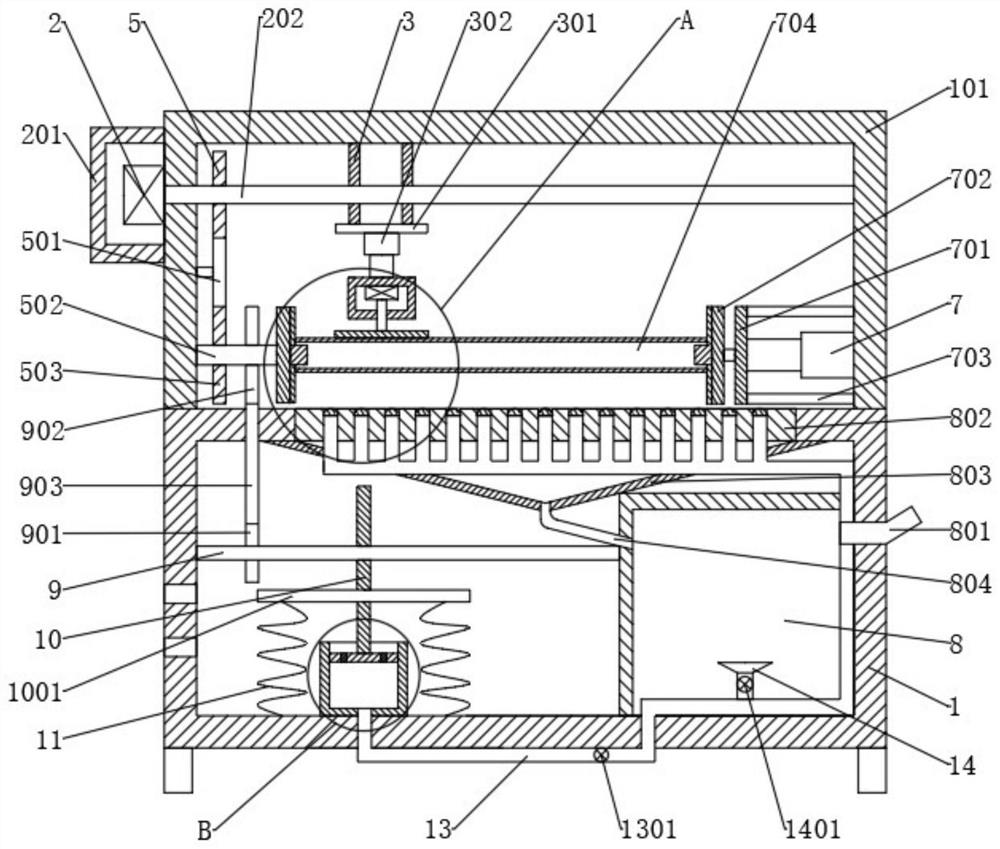

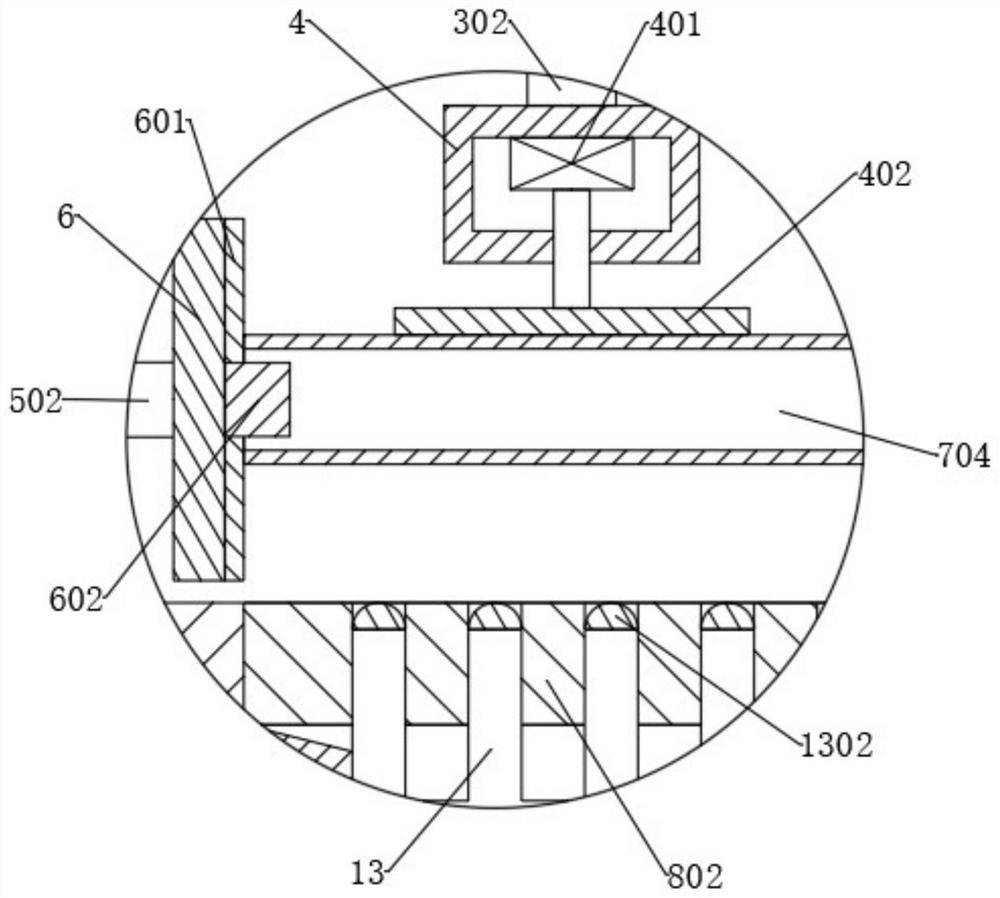

[0030] refer to Figure 1-4 , a kind of chemical mechanical polishing equipment, comprising a first box body 1, a support cover 101 and a part body 704, a moving mechanism is provided on the support cover 101, a lifting mechanism is provided at the bottom of the moving mechanism, and a second motor 401 is arranged in the lifting mechanism, The output end of the second motor 401 is provided with a polishing disc 402 that cooperates with the part body 704. The side wall of the support cover 101 is rotatably connected with a first rotating shaft 502, and the end of the first rotating shaft 502 away from the support cover 101 is fixedly connected with a second support plate. 6. The side wall of the support cover 101 is also fixedly connected with the second cylinder 7, the output end of the second cylinder 7 is connected with the third support plate 701, the third support plate 701 is rotatably connected with the rotation plate 702, and the part body 704 is fixed on the rotation B...

Embodiment 2

[0041] refer to Figure 1-4 , a kind of chemical mechanical polishing equipment, comprising a first box body 1, a support cover 101 and a part body 704, a moving mechanism is provided on the support cover 101, a lifting mechanism is provided at the bottom of the moving mechanism, and a second motor 401 is arranged in the lifting mechanism, The output end of the second motor 401 is provided with a polishing disc 402 that cooperates with the part body 704. The side wall of the support cover 101 is rotatably connected with a first rotating shaft 502, and the end of the first rotating shaft 502 away from the support cover 101 is fixedly connected with a second support plate. 6. The side wall of the support cover 101 is also fixedly connected with the second cylinder 7, the output end of the second cylinder 7 is connected with the third support plate 701, the third support plate 701 is rotatably connected with the rotation plate 702, and the part body 704 is fixed on the rotation B...

Embodiment 3

[0052] A method for using chemical mechanical polishing equipment, the following steps are used:

[0053] S1, start the second cylinder 7, and fix the part body 704;

[0054] S2, start the first motor 2, the first motor 2 drives the threaded rod 202 to rotate, the threaded rod 202 drives the component body 704 to rotate, and at the same time, the first rotating shaft 502 drives the second rotating shaft 9 to rotate;

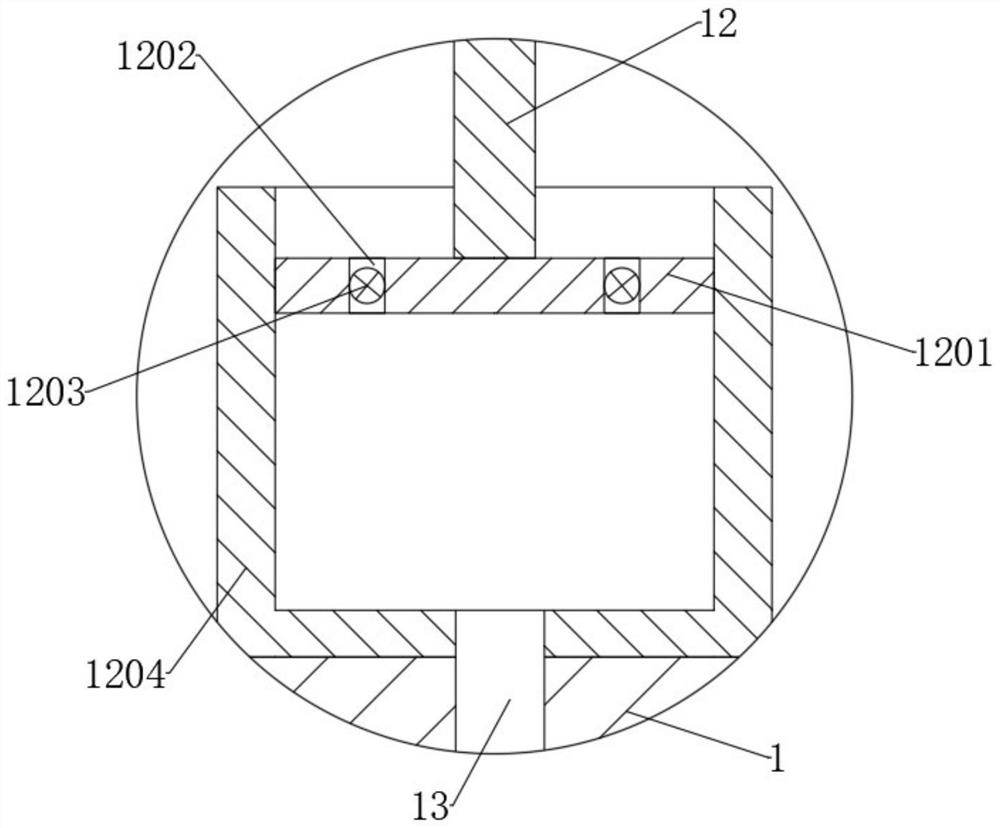

[0055] S3, the second rotating shaft 9 drives the piston plate 1201 to reciprocate through the cam 10, compressing the air in the piston barrel 1204 into the second hollow tube 13, so that the polishing solution in the second hollow tube 13 is sprayed from the nozzle 1302;

[0056] S4, start the first cylinder 302 and the second motor 401, make the polishing disc 402 contact with the part body 704, and polish the part body 704.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com