Rotatable mechanical jaw for visual sorting system

A sorting system and rotating machinery technology, applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve the problems of troublesome use, low applicability, complex structure, etc., and achieve the effects of high flexibility, reduced labor intensity, and ingenious ideas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

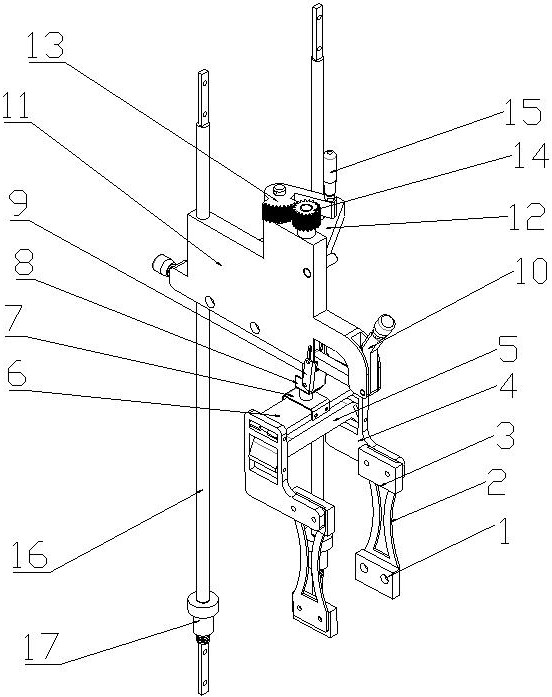

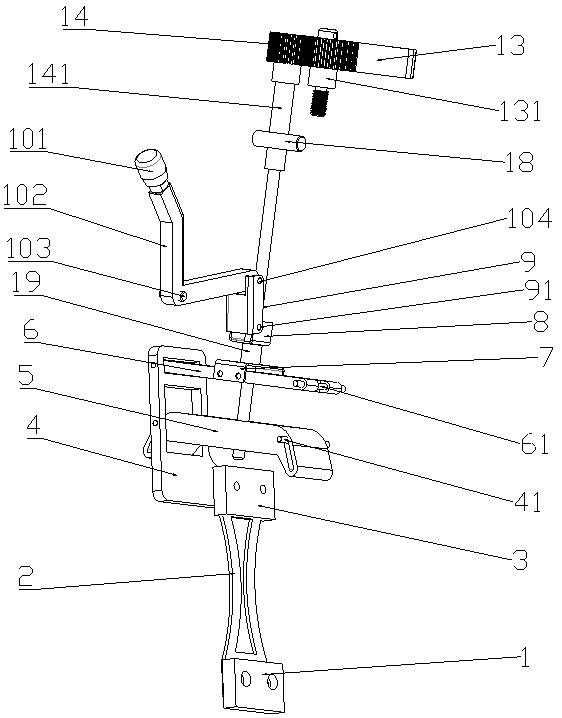

[0018] Embodiment 1: as Figure 1-6 As shown, a rotatable mechanical gripper used in a visual sorting system is mainly used to realize the automatic clamping of fresh cut flowers, including the lower rubber layer 1, the glass splint 2, the upper rubber layer 3, the side plate 4, the angle Adjusting plate 5, bearing plate 6, pull seat 7, pull seat set 8, upper pull block 9, buckle handle 10, main board 11, bottom plate 12, driving gear 13, driven gear 14, adjusting end cap 15, guide rod 16 , guide rod seat 17; limit shaft 18, pull shaft 19, side plate pin shaft 41, bearing plate pin shaft 61, upper pull block pin shaft 91, rotating handle 101, buckle hand connecting rod 102, buckle hand pin shaft I103, Buckle pin shaft II104, driving gear shaft 131, driven gear shaft 141.

[0019] The upper and lower ends of the inner side of the glass splint 2 are respectively equipped with an upper rubber layer 3 and a lower rubber layer 1 . The glass splint 2 is assembled on the side plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com