Perforating device and method for circuit board production

A technology of punching device and circuit board, applied in the field of wave recorder, can solve the problems such as inability to clamp and punch the circuit board, inconvenient adjustment of the distance between the drilling shafts, and long time for punching, so as to save the punching time. Time, wide application range, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

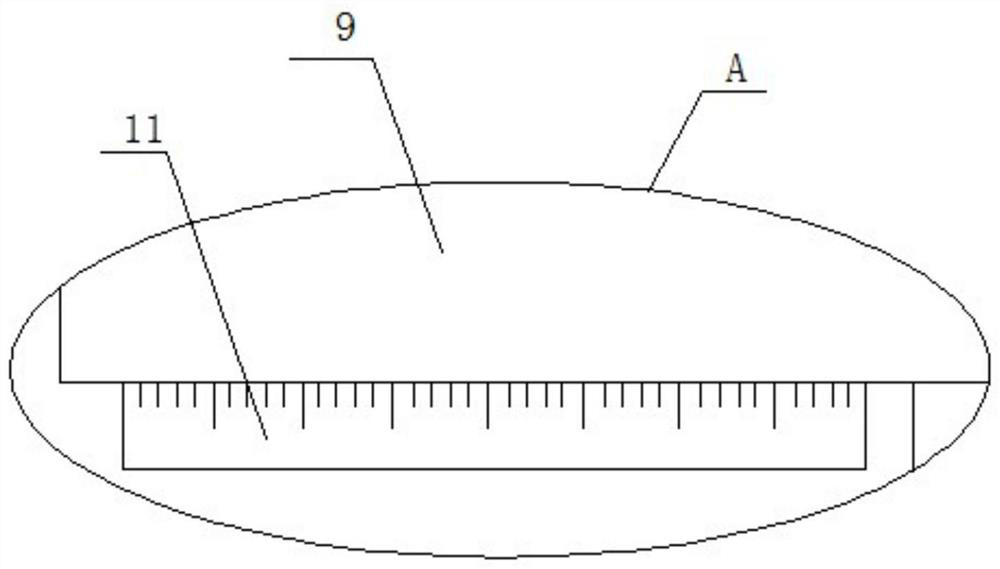

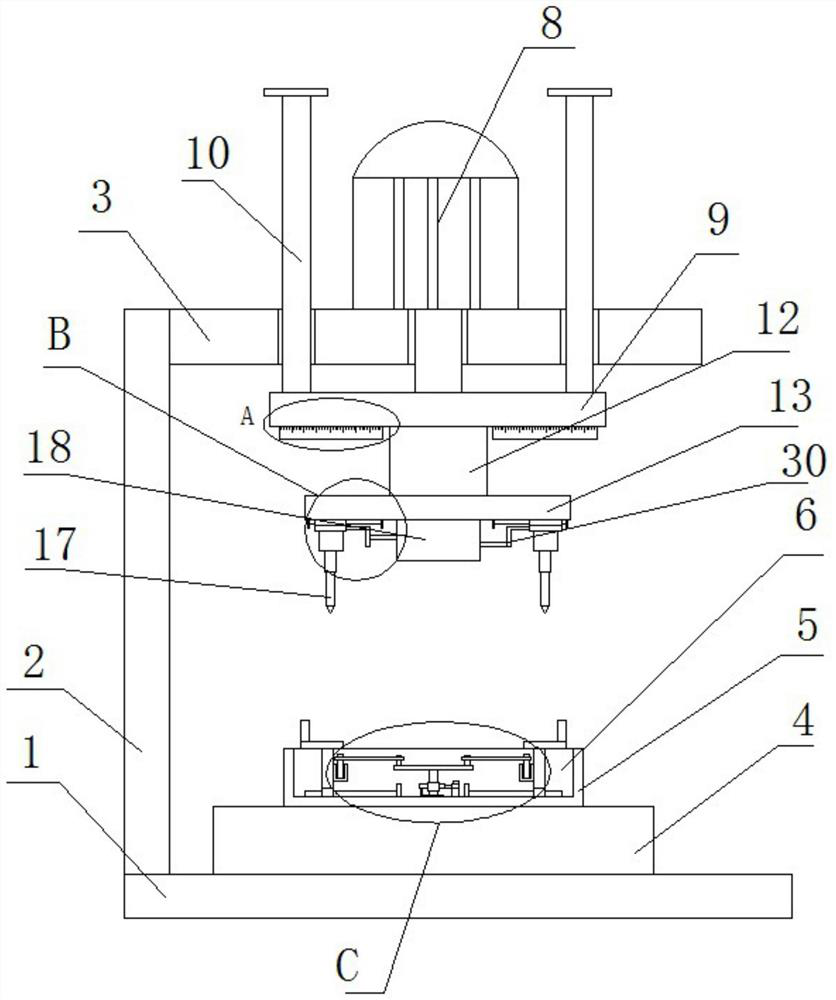

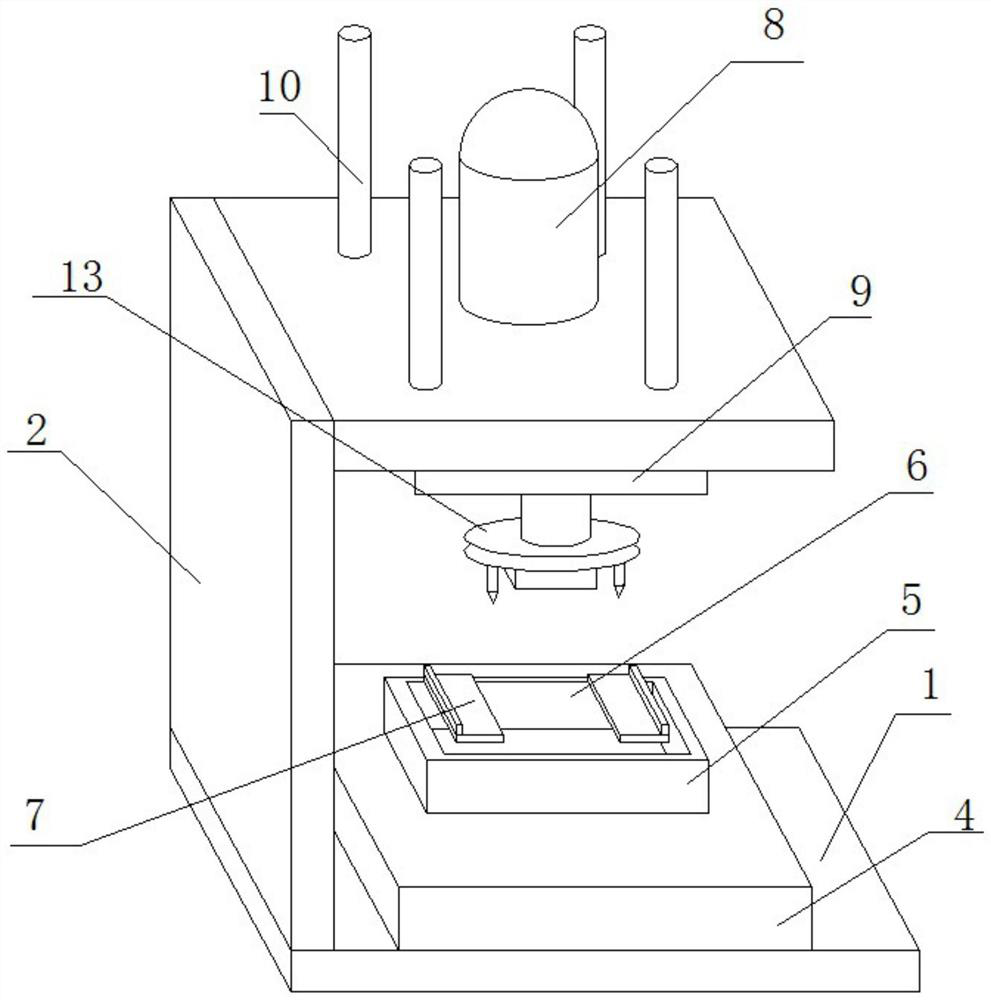

[0030] see Figure 1-6, the present embodiment provides a punching device for circuit board production, comprising a base 1, a vertical plate 2 is fixedly mounted on one side of the top of the base 1, and a mounting plate 3 is fixedly mounted on one side of the vertical plate 2, and the mounting plate 3 A platform 9 is slidingly installed at the bottom of the platform 9, and a lowering assembly is provided on the platform 9, a workbench 4 is fixedly installed on the top of the base 1, a placement block 5 is fixedly installed on the top of the workbench 4, and a rotating motor 12 is fixedly installed on the bottom of the platform 9. , the bottom of the output shaft of the rotating motor 12 is fixedly equipped with a disc 13, and the bottom of the disc 13 is fixedly equipped with an adjustment block 18, and the adjustment block 18 is provided with a chamber 19, and the bottom inner wall of the chamber 19 is rotatably installed with two Driven shafts 23, two driven shafts 23 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com