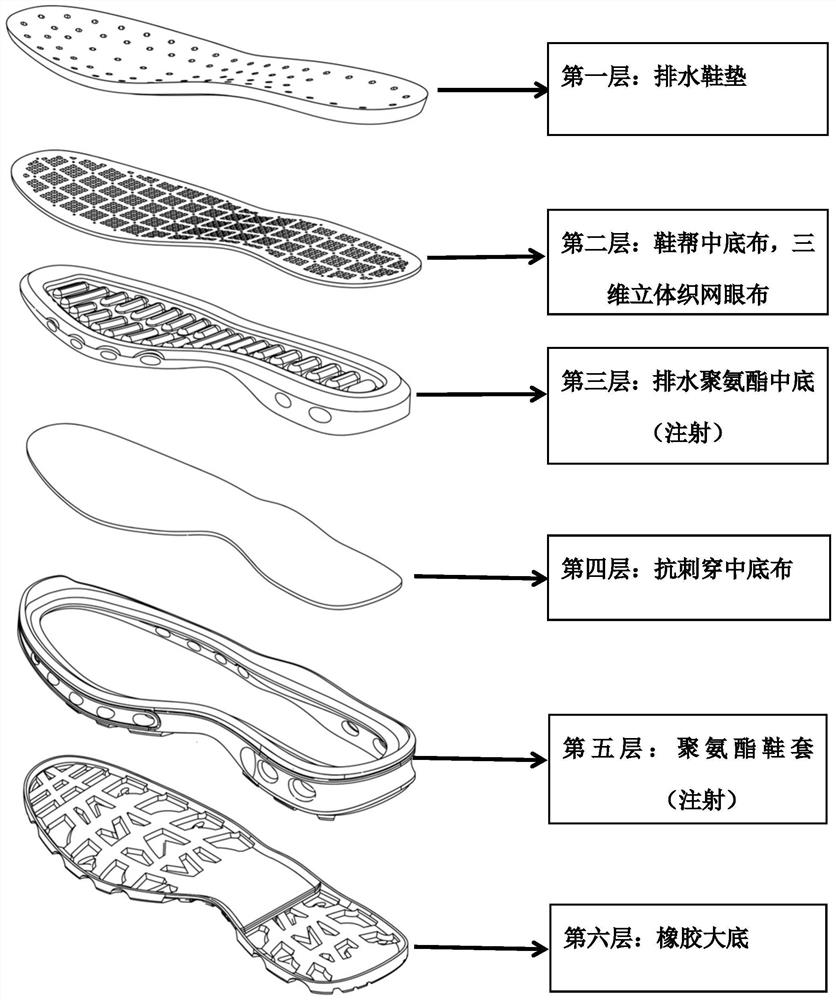

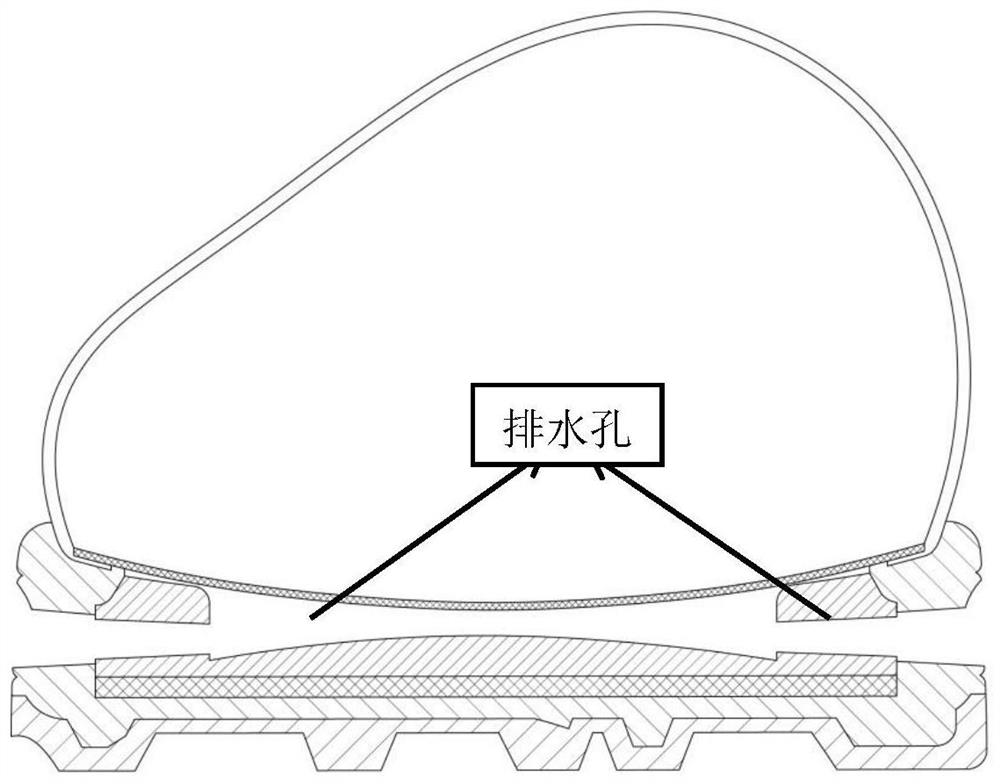

Functional protective boots with drainage and anti-puncture functions and manufacturing method thereof

A production method and anti-puncture technology, applied to soles, clothing, footwear, etc., to achieve comfortable wearing and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The experimental methods used in the following examples are conventional methods unless otherwise specified.

[0026] The materials and reagents used in the following examples can be obtained from commercial sources unless otherwise specified.

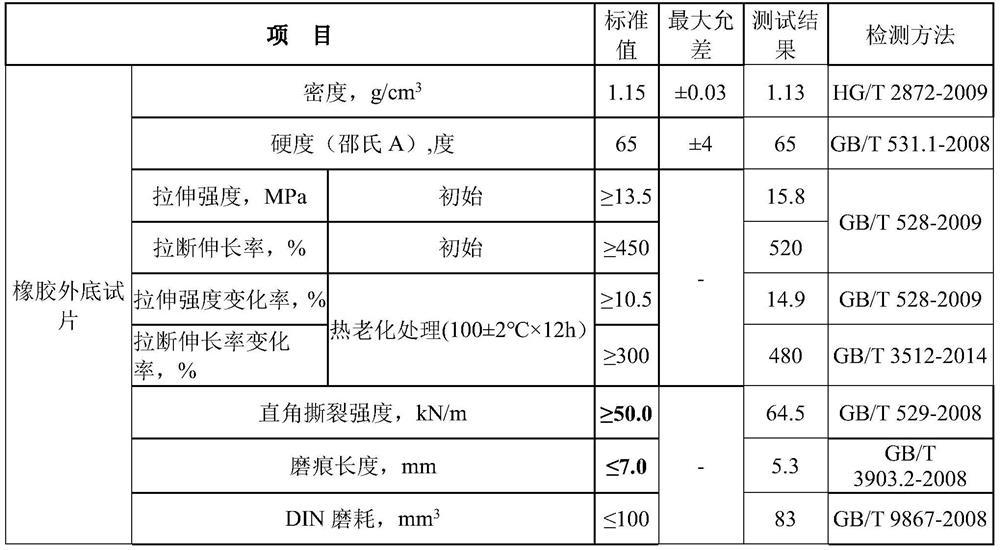

[0027] The formula of the rubber outsole that the present invention adopts is as follows:

[0028] 60-70 parts of nitrile rubber, 20-30 parts of natural rubber, 15-20 parts of butadiene rubber; 35-40 parts of precipitated white carbon black, 5 parts of naphthenic oil, 3 parts of SI-69 silane coupling agent, hard 1 part of fatty acid, 1 part of anti-aging agent trimethyldihydroquinoline polymer + 1 part of 2-mercaptobenzimidazole MB, 5-10 parts of active zinc oxide, polyethylene glycol PEG-4000 white carbon black active agent 3.5 servings.

[0029] Specifically, test the performance of the rubber outsole test piece made by following formula below:

[0030] 60 parts of nitrile rubber, 22 parts of natural rubber, 18 parts of but...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com