Ship floating body device with high seakeeping performance

A high seakeeping and ship technology, applied in the direction of hull, hull design, ship construction, etc., can solve the problems of long design and construction period, complex structure form, waste of materials, etc., achieve fast, stable and safe navigation, reduce wave resistance, reduce The effect of small waterplane area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

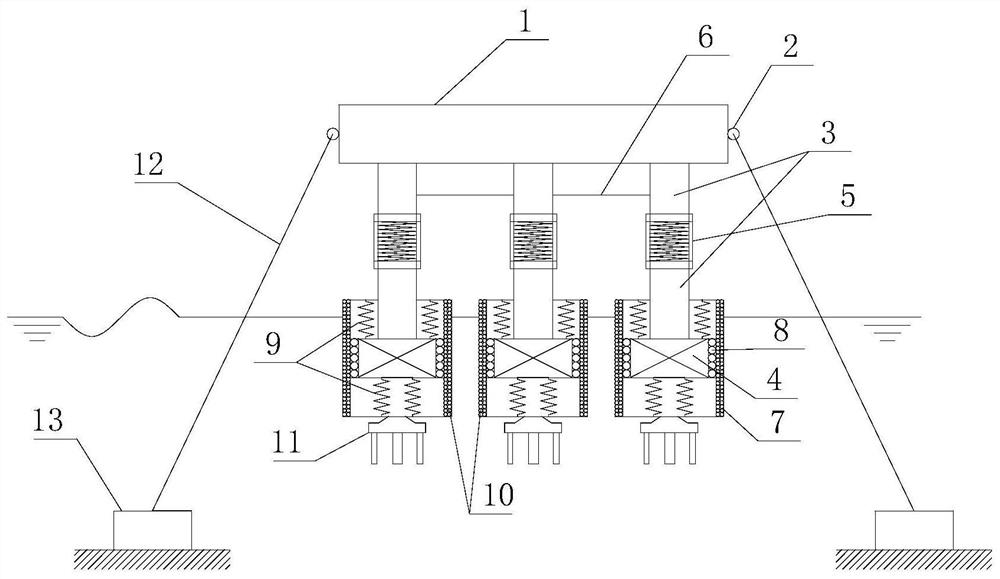

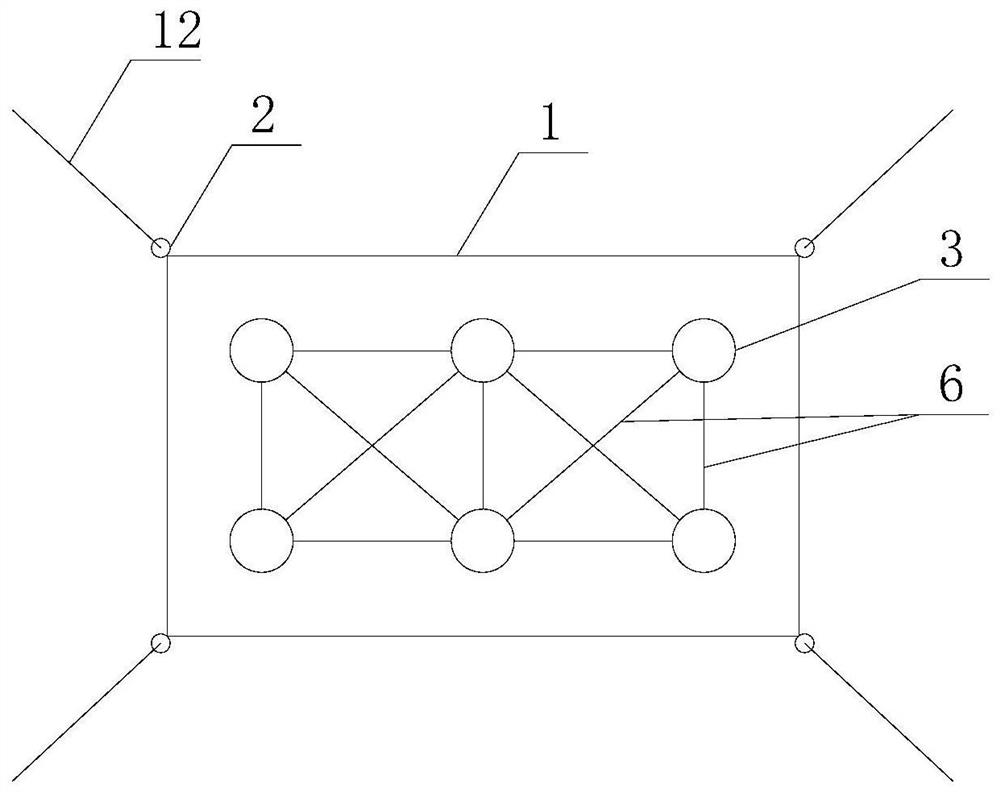

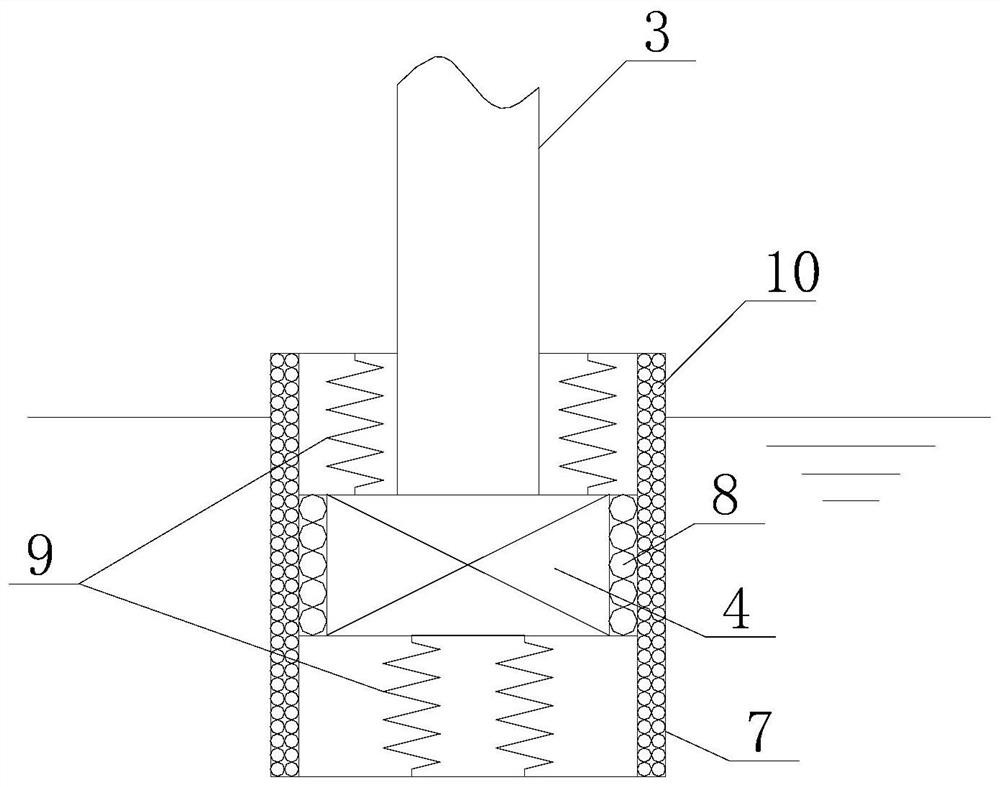

[0026] Such as figure 1 As shown, a high seakeeping ship floating body device, including superstructure, columns, buoys and mooring system.

[0027] The superstructure is a box-shaped structure, and several holes are arranged at the bottom thereof, and each hole is used to connect and fix with the upper end of each column. There are hanging rings at the four corners of the superstructure box body, and the hanging rings are used to connect anchor chains, so as to moor and fix the floating body device of the ship. Multiple cabins are set in the superstructure for carrying passengers and cargo or as a production operation platform.

[0028] A total of six cylindrical columns are used, the upper end of each column is connected to the superstructure, and the lower end is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com