Garbage can

A technology for garbage cans and garbage bags, applied in the field of garbage cans, can solve the problems of poor user experience, tearing garbage bags, and high requirements, and achieve the effects of good user experience and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

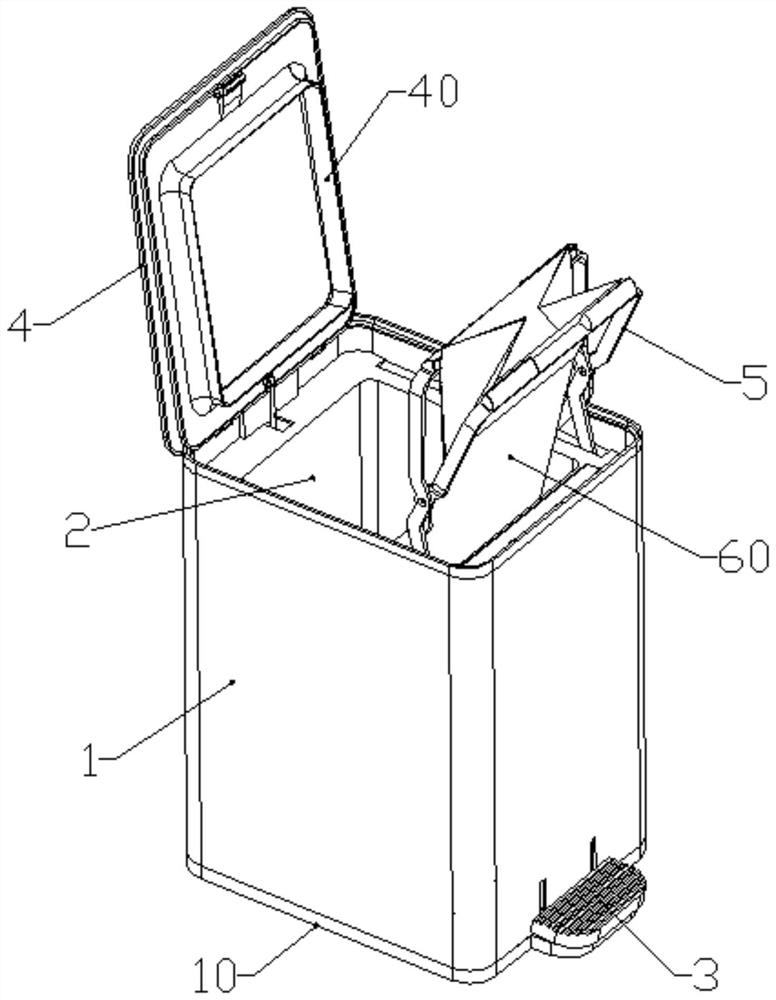

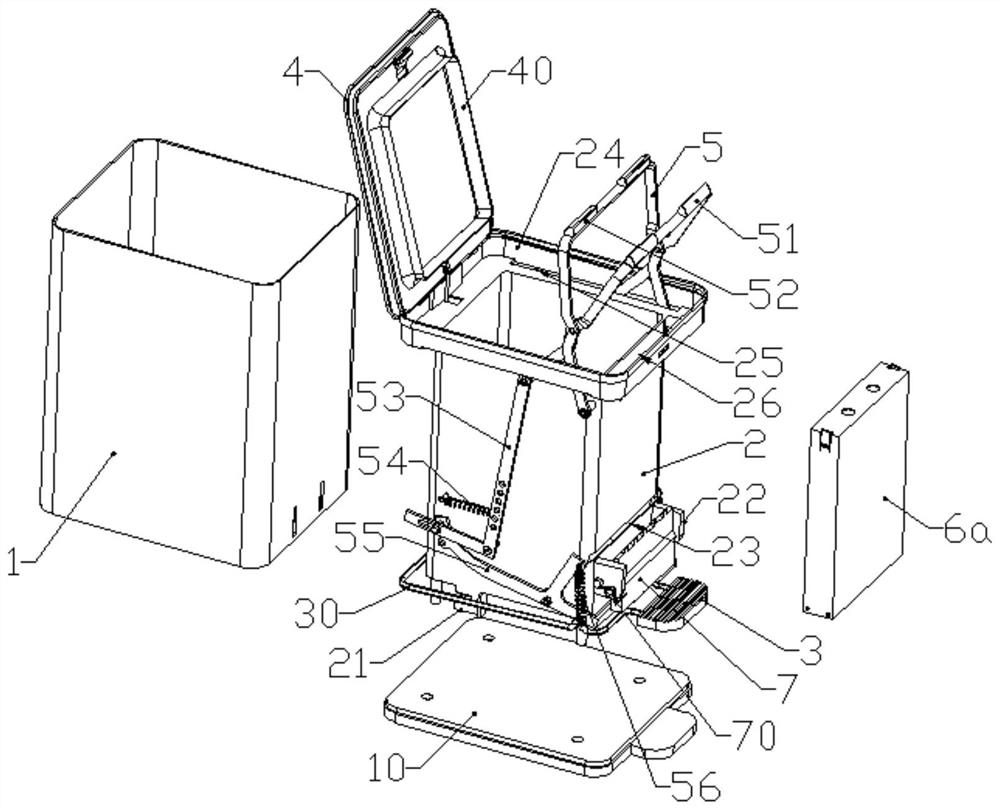

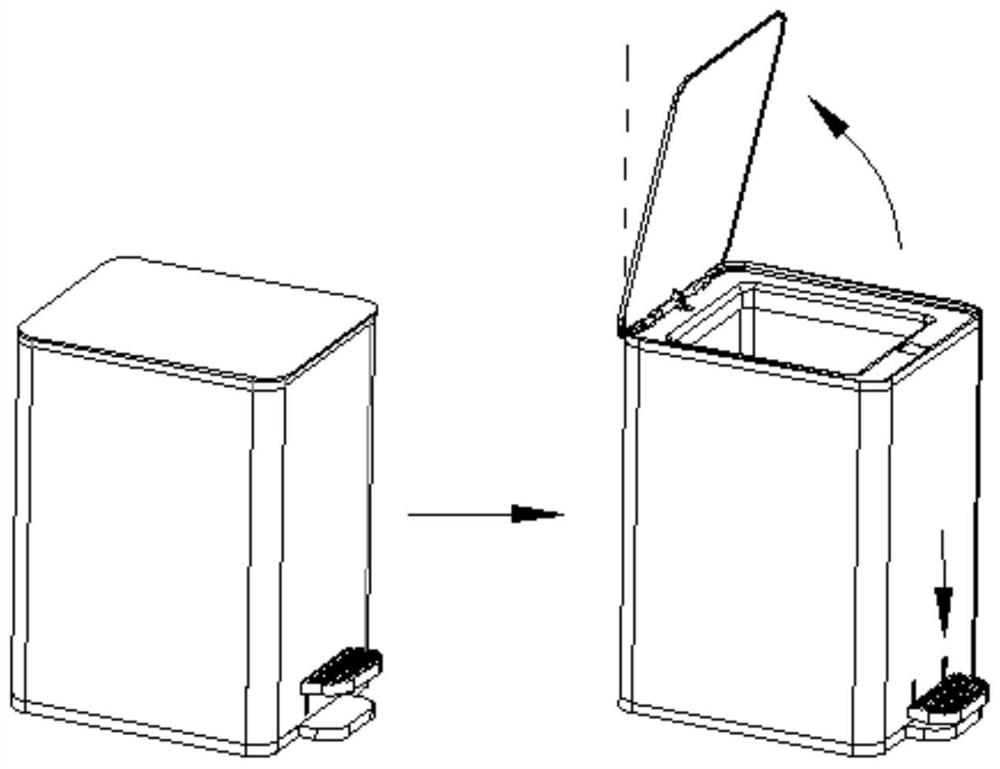

[0051] according to Figure 1 to Figure 12 As shown, a trash can in this embodiment includes: an outer bucket 1 and an inner bucket 2 , and the inner bucket 2 is fixedly or detachably installed in the outer bucket 1 . The trash can also includes a bung 4, which is rotatably mounted on the rear side of the upper end of the inner bucket 2, and a cover opening strut 41 is rotatably connected to the bung 4 near the rotating shaft, and the bung 4. There is a strut seat that is rotatably connected with the lid-opening strut 41 on the inner side; when the lid-opening strut 41 moves upwards, it drives the bucket lid 4 to rotate upwards. Further, the connecting position between the inner bucket 2 and the bung 4 can be provided with a limiting part that limits the rotation range of the bung 4, such as limiting the rotation range of the bung 4 to 0-120 degrees (0 degrees is the position where the bung 4 is closed. level status).

[0052] In order to make the opening action of the trash...

Embodiment 2

[0086] The difference between this embodiment and embodiment 1 is that the structure of the garbage bag is modified. Specifically, such as Figure 17 As shown, the garbage bag 60 is provided with a first welding line 603a along the width direction near the bottom, and the second broken line 604b is located below the first welding line; the garbage bag 60 is located in the range of the first welding line 603a A plurality of unlocking holes 605 are arranged inside along the width direction, and at least one of the unlocking holes 605 serves as the unlocking portion.

[0087] Such as Figure 18 As shown, the garbage bag 60 is provided with a first welding line 603a along the width direction near the bottom, and the second broken line 604b is located below the first welding line; the garbage bag 60 is provided with a handle near the mouth of the bag. The hole 606, the handle hole 606 also serves as the unlocking part.

[0088] Figure 18 The handle hole 606 shown is in the sha...

Embodiment 3

[0091] The difference between this embodiment and Embodiment 1 is that the first bag box 6a is replaced by the second bag box 6b: the same parts in the second bag box 6b as the first bag box 6a are denoted by the same reference numerals. Specifically, combine Figure 22 As shown, the second bag box 6b of this embodiment is loaded into the trash can from the front side of the outer bucket 1. Compared with the way of loading from the top of the inner bucket 2, the way of loading from the front side of the outer bucket 1 avoids bag opening clips. 5 possible obstacles.

[0092] Further, combine Figure 23 , Figure 24 As shown, the box body includes an outer box 61 with a side opening, and an inner box 62 with an upper end opening, and a plurality of garbage bags connected by dotted lines are installed in the inner box and along the height direction of the inner box 62 stack.

[0093] A bag channel 63 for the garbage bag 60 to pass through from top to bottom is formed between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com