A method for preparing cuprous oxide from scrap copper-tungsten alloy

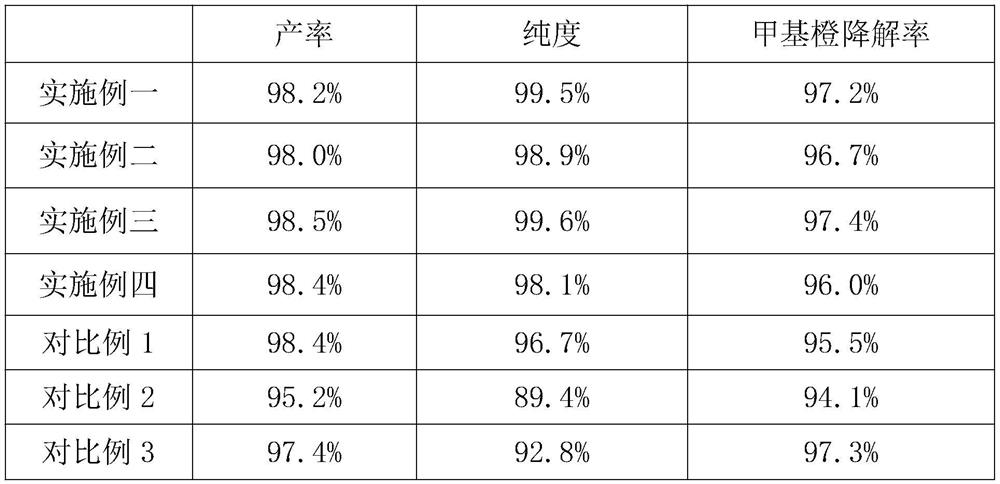

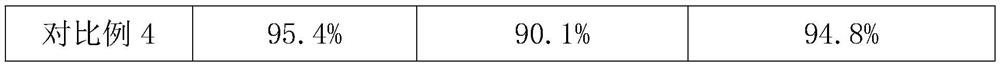

A technology of copper-tungsten alloy and cuprous oxide, which is applied in the direction of copper oxide/copper hydroxide, etc., can solve the problems of the influence of the reducing agent's reductive strength and concentration on the product purity and yield, the decrease in yield, and the decrease in the purity of cuprous oxide. Achieve the effect of simple and time-saving preparation process, increase yield and improve purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The present invention provides a method of preparing an oxide apron based on a scrap copper tungsten alloy comprising the steps of:

[0036] (1) First ground the scrap copper tungsten alloy into a micron granulation, and then poured into a concentration of 2 mol / L nitric acid solution for 50 min, and the reaction process continued to be stirred to ensure sufficient reaction, and the reaction was filtered and the reaction was completed. Remove the copper nitrate solution, spare;

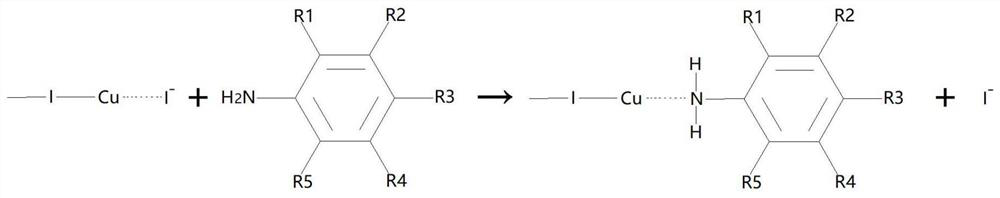

[0037] (2) Mix the copper nitrate solution to an excess iodine salt solution, and then add a reductant solution having a concentration of 1 mol / L to reduce the reaction for 2 h. The reaction process is continuously stirred, and the reaction is completed to obtain a complexion ion [Cui 2 ] - Mixed solution; add an aniline compound C to the mixed solution C 6 NH 2 R1R2R3R4R5 was stirred for 60 min to form flocculation, filtered flocculation and washed clean and spare by water.

[0038] (3) Pour t...

Embodiment 2

[0041] The present invention provides a method of preparing an oxide apron based on a scrap copper tungsten alloy comprising the steps of:

[0042] (1) First ground the waste copper tungsten alloy into a micron granulation, and then poured into a concentration of 5 mol / L nitric acid solution for 50 min, and the reaction process continued to be stirred to ensure sufficient reaction, and the reaction was filtered and the reaction was completed. Remove the copper nitrate solution, spare;

[0043] (2) Mix the copper nitrate solution with an excess iodine salt solution, then adding a reductant agent solution having a concentration of 4 mol / L for reduction reaction for 1 h, the reaction process continues to stir, and the reaction is completed to obtain a complexion ion [Cui 2 ] - Mixed solution; add an aniline compound C to the mixed solution C 6 NH 2 R1R2R3R4R5 was stirred for 80min to form flocculation, filtered flocculation and washed clean and spare by water.

[0044] (3) Pour t...

Embodiment 3

[0047] The present invention provides a method of preparing an oxide apron based on a scrap copper tungsten alloy comprising the steps of:

[0048] (1) First ground the waste copper tungsten alloy into a micron granulation, and then poured into a concentration of 3 mol / L nitric acid solution for 60 min, and the reaction process continued to be stirred to ensure sufficient reaction, and the reaction was filtered and the reaction was completed. Remove the copper nitrate solution, spare;

[0049] (2) Mix the copper nitrate solution with an excess iodide solution, and then add a concentration of 2 mol / L to a reducing agent solution for reduction reaction 1.5H, and the reaction process is continuously stirred, and the reaction is completed to obtain a complex ion [Cui 2 ] - Mixed solution; add an aniline compound C to the mixed solution C 6 NH 2 R1R2R3R4R5 is stirred for 70min to form flocculation, filtrate flocculation and clean it with water;

[0050] (3) Pour the cleansing floc ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com