Production equipment and production method of melaleuca alternifolia leaf oil antibacterial wet tissues

A technology of Melaleuca alternifolia and production equipment is applied in the field of production equipment for antibacterial wet wipes with Melaleuca alternifolia oil, which can solve uneven soaking of non-woven fabrics, reduce the antibacterial effect of wet wipes, and affect the overall quality of wet wipes, etc. problems, to achieve the effect of improving the antibacterial effect and overall quality, improving the quality of wet wipes, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

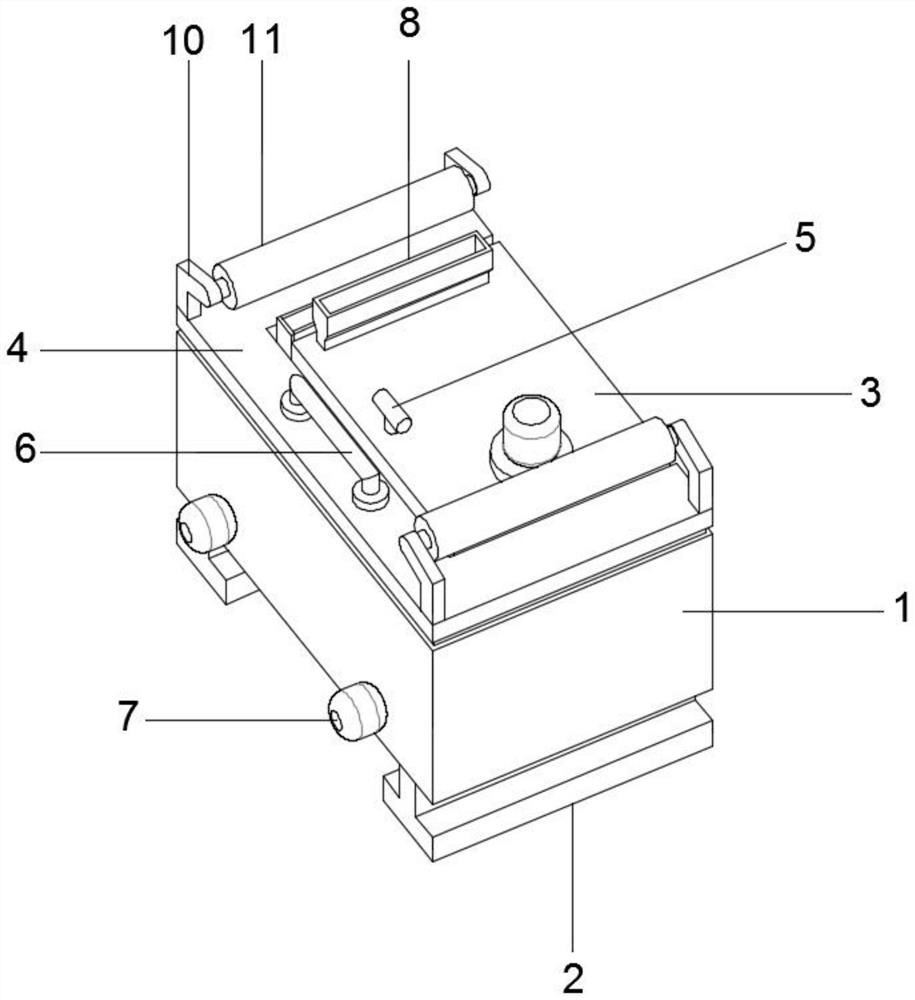

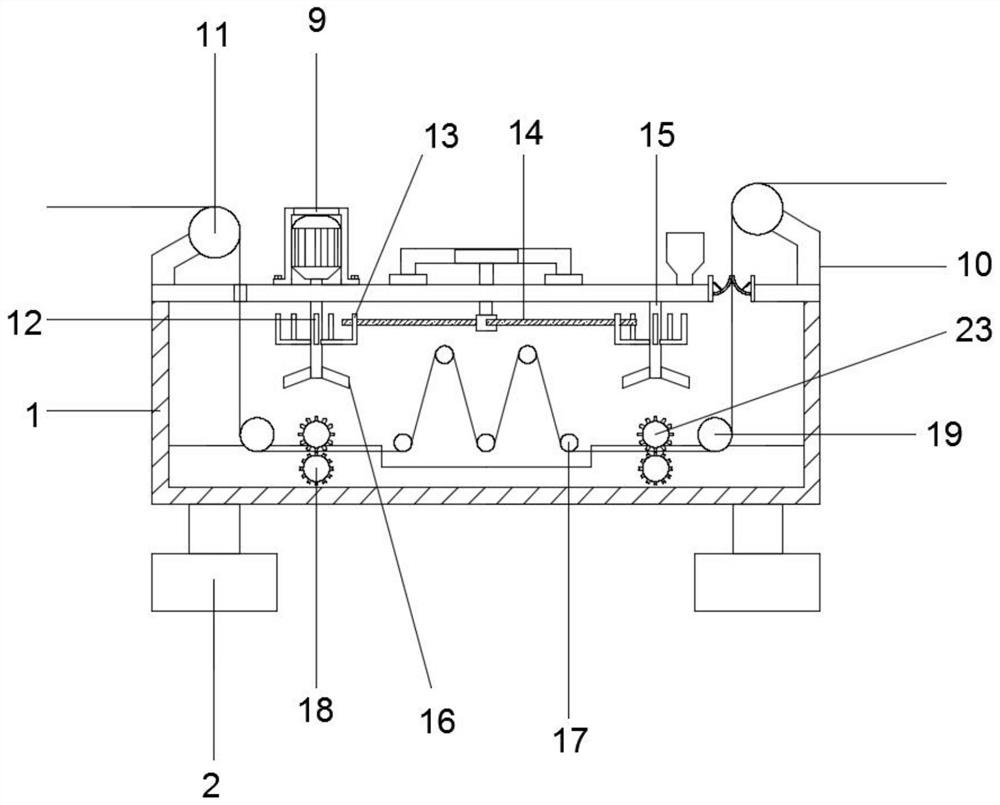

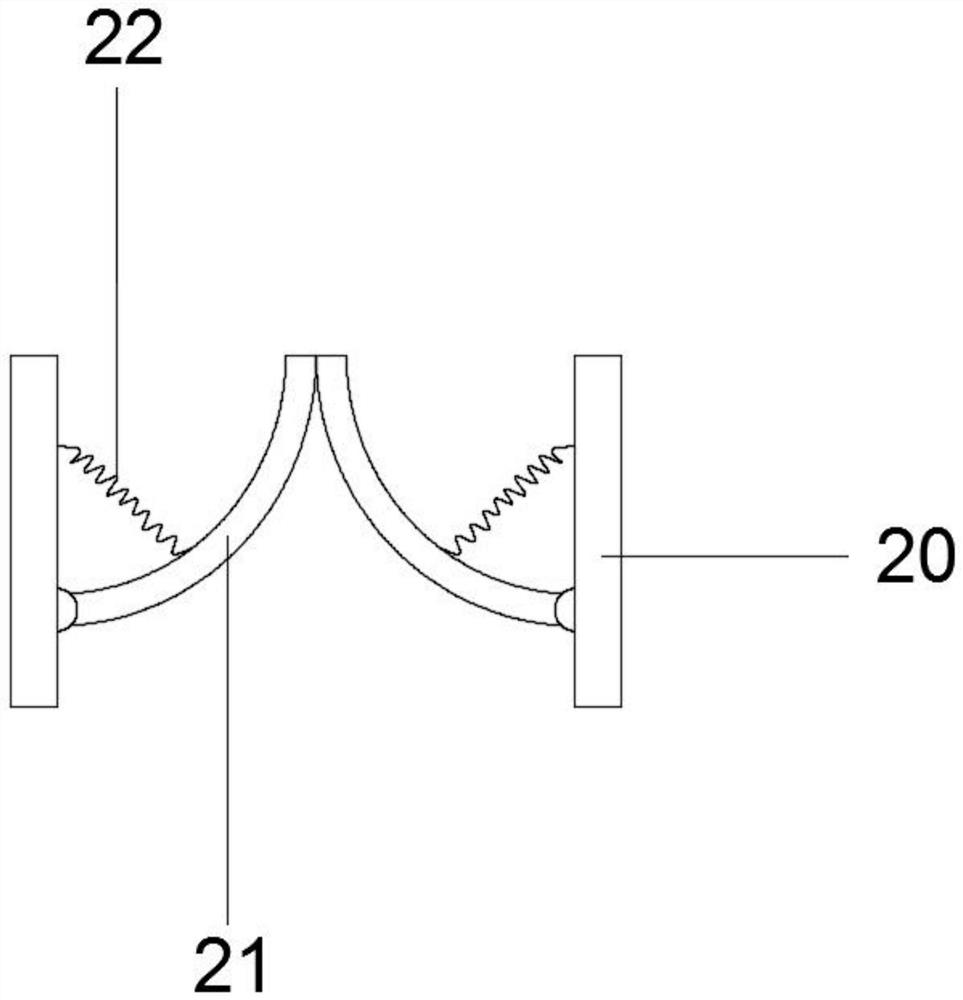

[0030] refer to Figure 1-5 , a production equipment and production method of Melaleuca alternifolia oil antibacterial wet wipes, comprising soaking box 1 and support 10, the components of a kind of Melaleuca alternifolia oil antibacterial wet wipes and the mass parts of each component are respectively : Water (up to 100%), Melaleuca alternifolia oil (0.1-0.5%), glycerin (0.5-2%), Tween-20 (0.1-2%), benzalkonium chloride (0.05-0.1%) ), polyurethane biguanide (0.05~0.1%); one side of the top outer wall of the soaking tank 1 is connected with a case cover 3 by a hinge, and the top outer wall of the case cover 3 is fixed with a disturbance motor 9 by screws, and the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com